High-speed motor provided with variable air channel

A high-speed motor and air duct technology, applied in synchronous motors with stationary armatures and rotating magnets, mechanical equipment, electric components, etc., can solve the problems of high processing tolerance requirements, rising processing costs, and increasing the weight of the whole machine. Achieve the effect of reducing machining accuracy requirements, facilitating manufacturing and processing, and reducing the quality of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

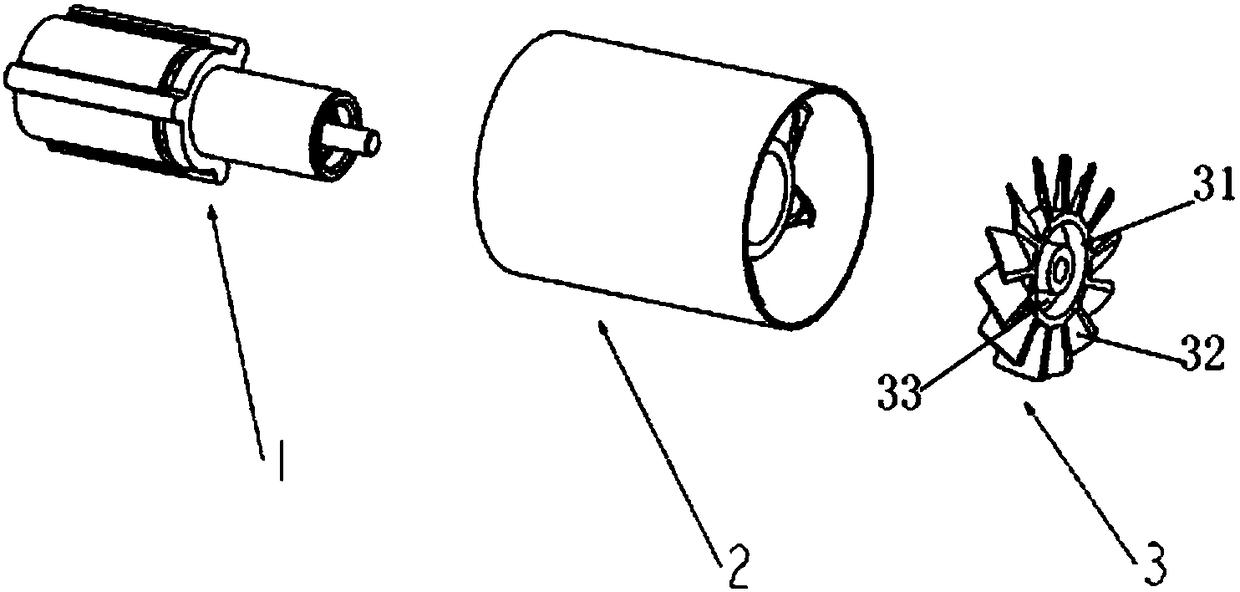

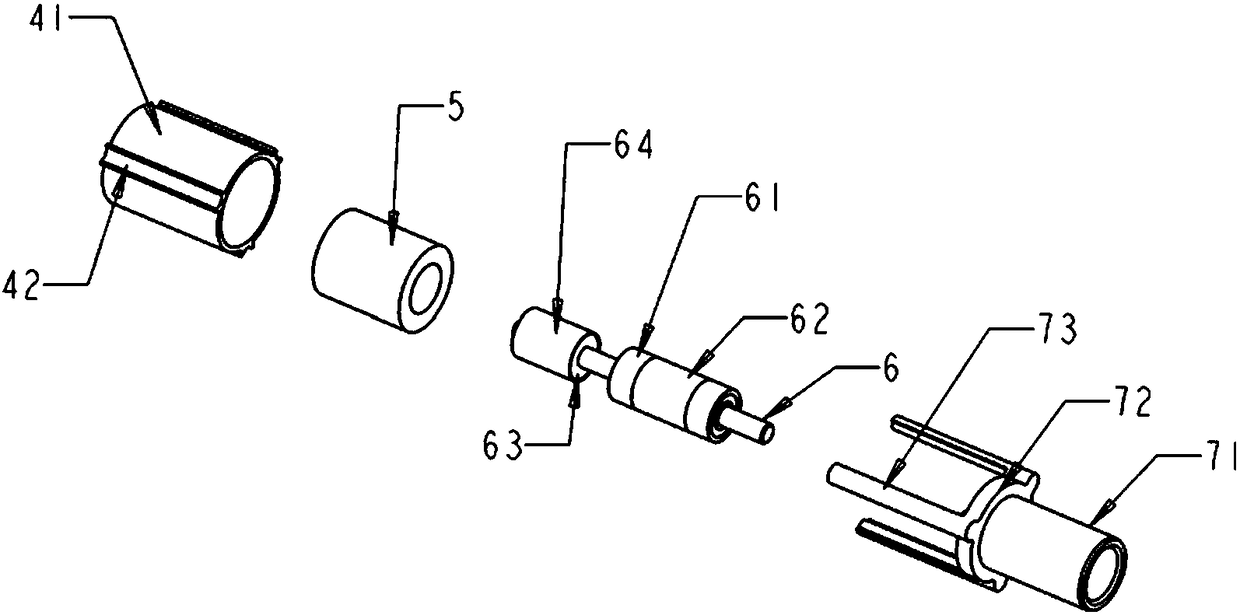

[0019] Such as Figure 1 to Figure 3 As shown, a variable air duct high-speed motor of the present invention includes a motor assembly 1, a hollow air duct 2 and an impeller 3, a hollow air duct 2 is provided outside the motor assembly 1, and one end of the motor assembly 1 is sleeved with the impeller 3; The motor assembly 1 is composed of a stator assembly, a rotor assembly and a casing 7; the casing 7 is used to connect and protect internal parts; the stator assembly includes a stator core 4 and a coil winding 5 arranged inside the stator core 4, and the rotor assembly includes There is a rotor core 6, and a bearing assembly is sleeved on the rotor core 6. The end of the rotor core 6 is sleeved with NdFeB permanent magnet salient poles 63 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com