Amplitude controllable material fretting wear test device

A fretting wear and test device technology, which is used in measuring devices, analyzing materials, testing wear resistance, etc., to achieve the effects of strong practicability, convenient operation, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

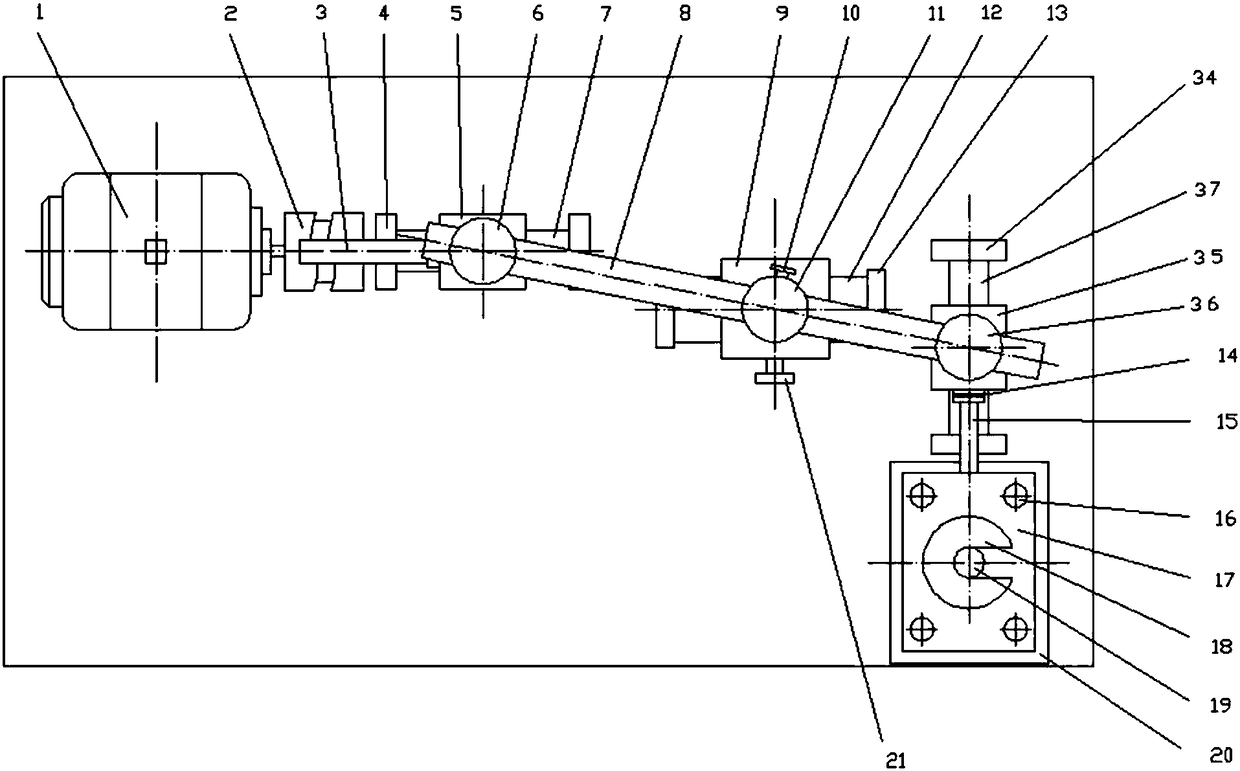

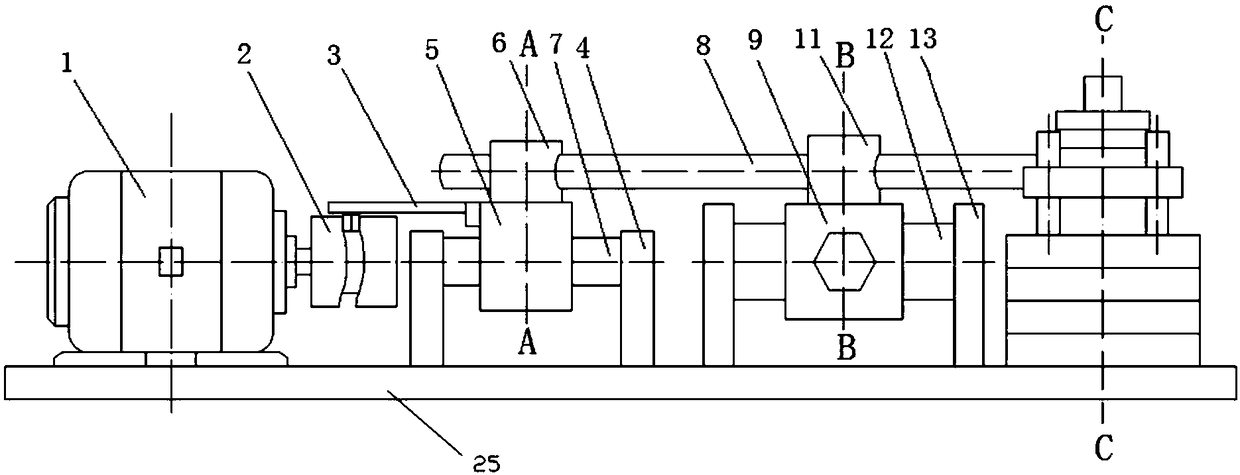

[0025] See attached figure 1 , 2 , a material fretting wear test device with controllable amplitude, comprising: a base 25 and a frequency modulation motor 1 mounted on the base 25, a first circular slide rail frame 4, a second circular slide rail frame 34, a square slide rail frame 13 and an oil tank 26.

[0026] See attached figure 1 , figure 2 and Figure 4 A cylindrical cam 2 is coaxially installed on the output shaft of the frequency modulation motor 1, and by adjusting the speed of the frequency modulation motor 1, the specimen can be subjected to wear tests at different frequencies. The axial ends of the first circular slide rail 7 are respectively affixed to the first circular slide rail frame 4, thereby being supported on the first circular slide rail frame 4; the first linear bearing 5 with one end connected to the cam push rod 3 is support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com