Pipeline Laying Method for Preventing Corrosion in Moisture Gathering Pipeline

A laying method and internal corrosion technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as poor anti-corrosion effect, prevent accidents, prevent internal corrosion, and maximize economic benefits. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

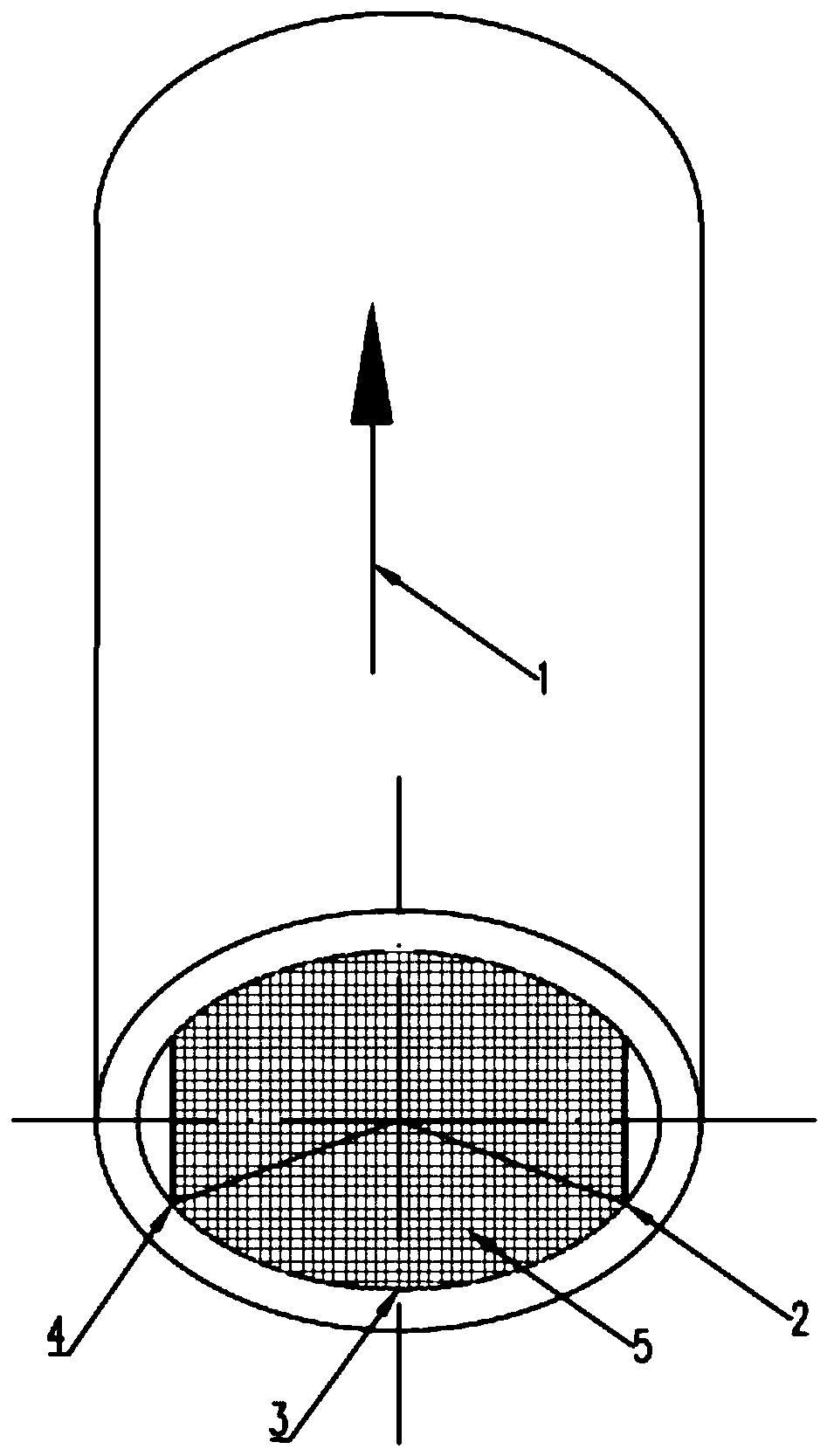

[0032] The invention provides a pipeline laying method for preventing internal corrosion of a moisture gathering pipeline, which specifically includes the following steps:

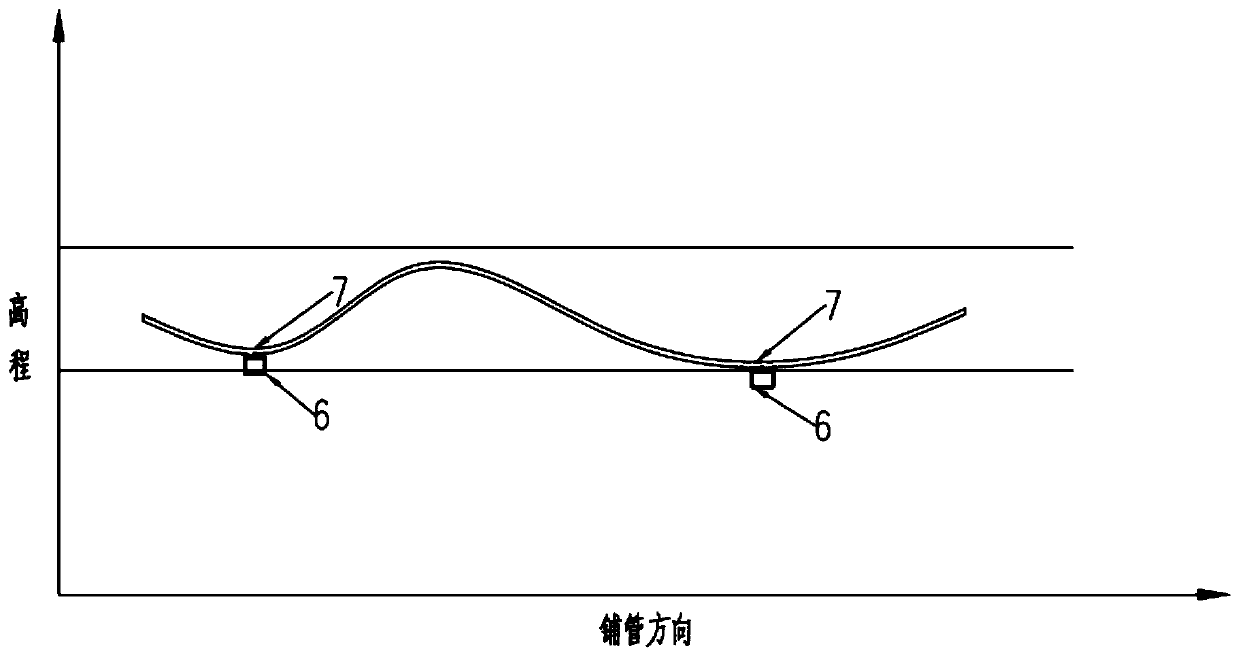

[0033] 1) Draw the pipeline elevation map;

[0034] 2) Collect low point position information in the pipeline elevation map;

[0035] 3) Calculate a low position M 0 and the nearest neighbor high point position M 1 elevation difference A 1 and the low point position M 0 and the second nearest neighbor high point position M 2 elevation difference A 2 ;

[0036] 4) Judging the elevation difference A 1 , Elevation difference A 2 with critical value A 0 The relationship between, modify the pipeline elevation map by raising the high point or lowering the low point, so that the low point position M 0 The elevation difference between the two neighboring high points is greater than or equal to the critical value A 0 ;Threshold A 0 The determination should take into account the characteristics of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com