A shift fork control method for engaging and removing gears of a single taper lock ring synchronizer

A technology of synchronizer and lock ring, which is used in transmission control, components with teeth, belt/chain/gear, etc., can solve the problems of car limp state, damage to the box, etc., to shorten the action time and reduce the number of synchronizers. The effect of action failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

[0034] The present invention can be implemented in many different forms, and should not be construed as being limited to the embodiments set forth herein. On the contrary, these embodiments are provided so that this disclosure will be thorough and complete. In the drawings, the sizes and relative sizes of structures and regions are exaggerated for clarity.

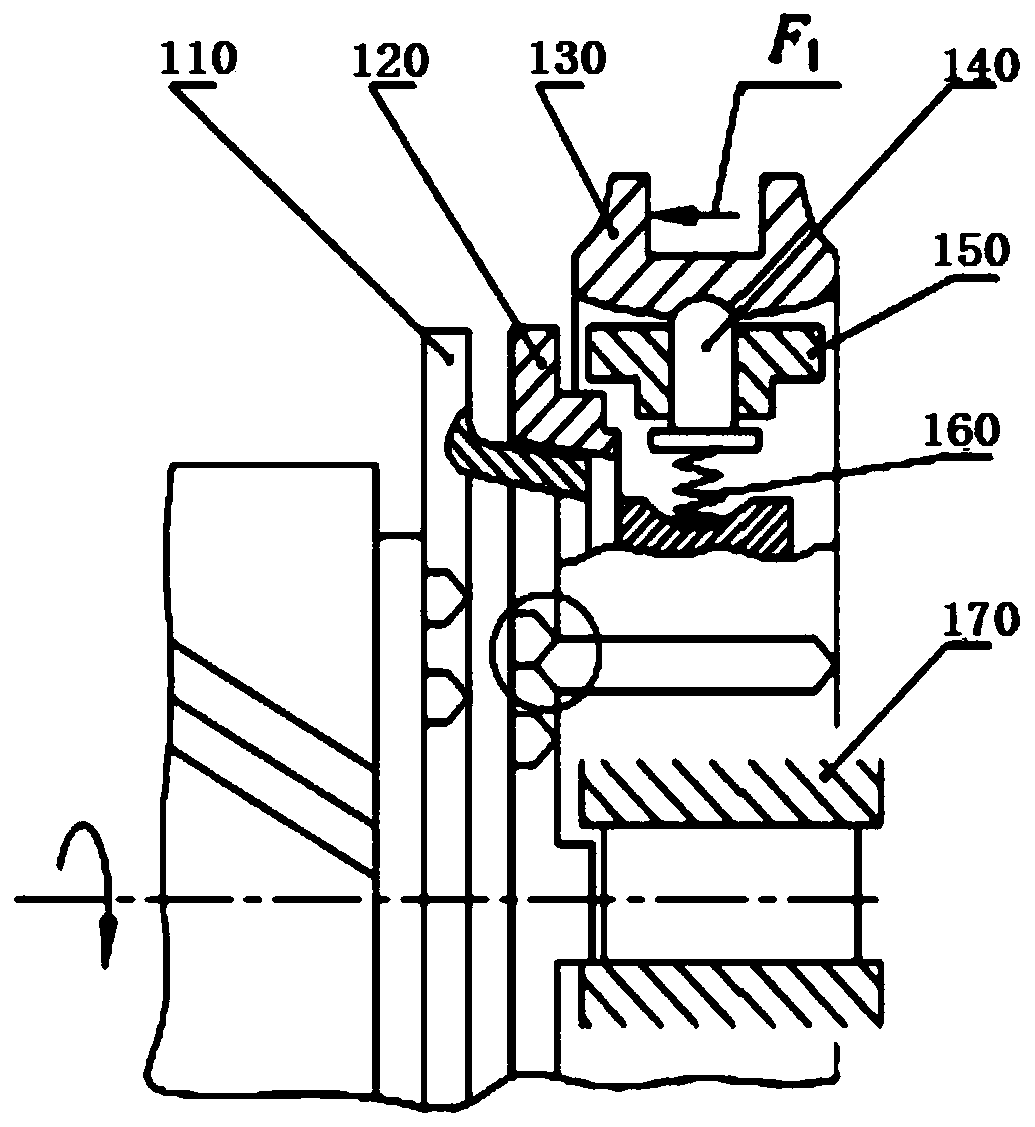

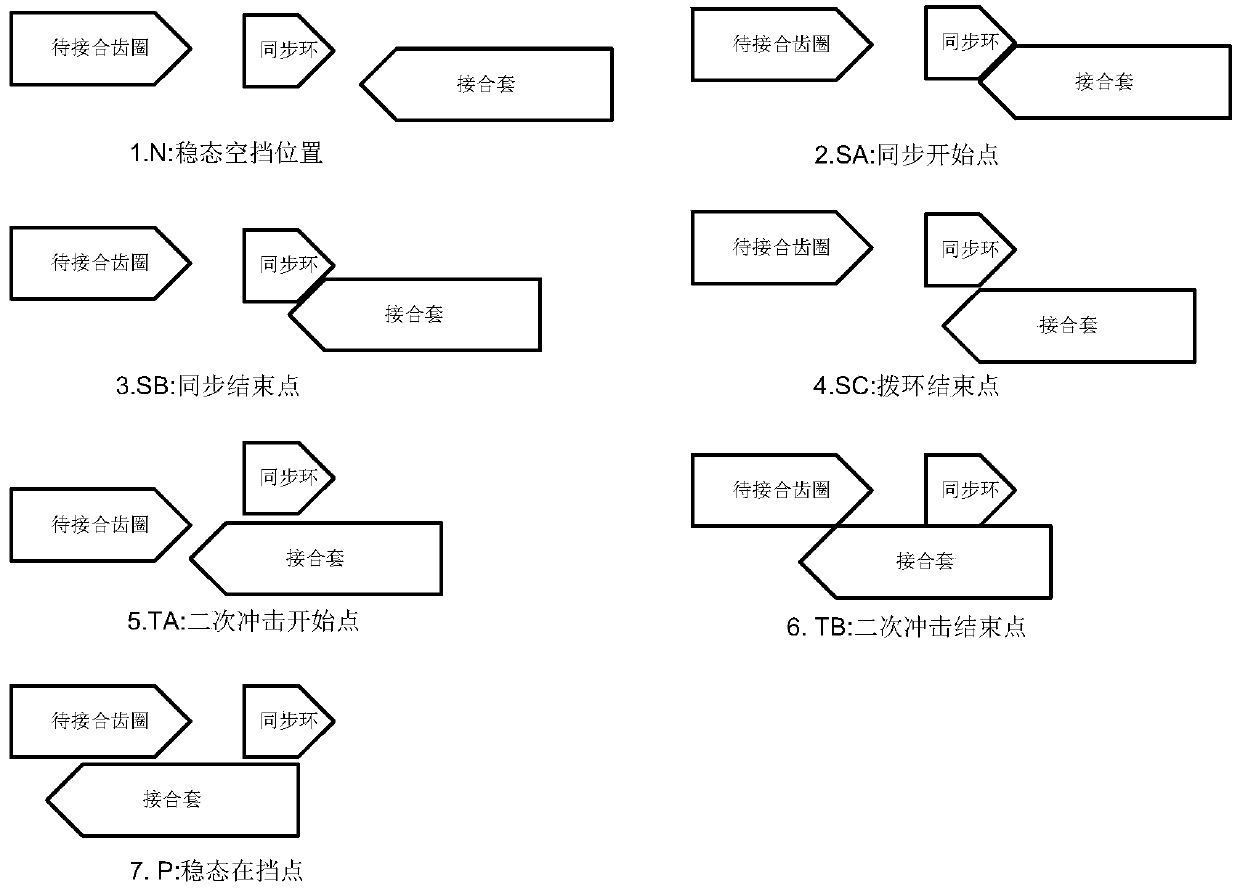

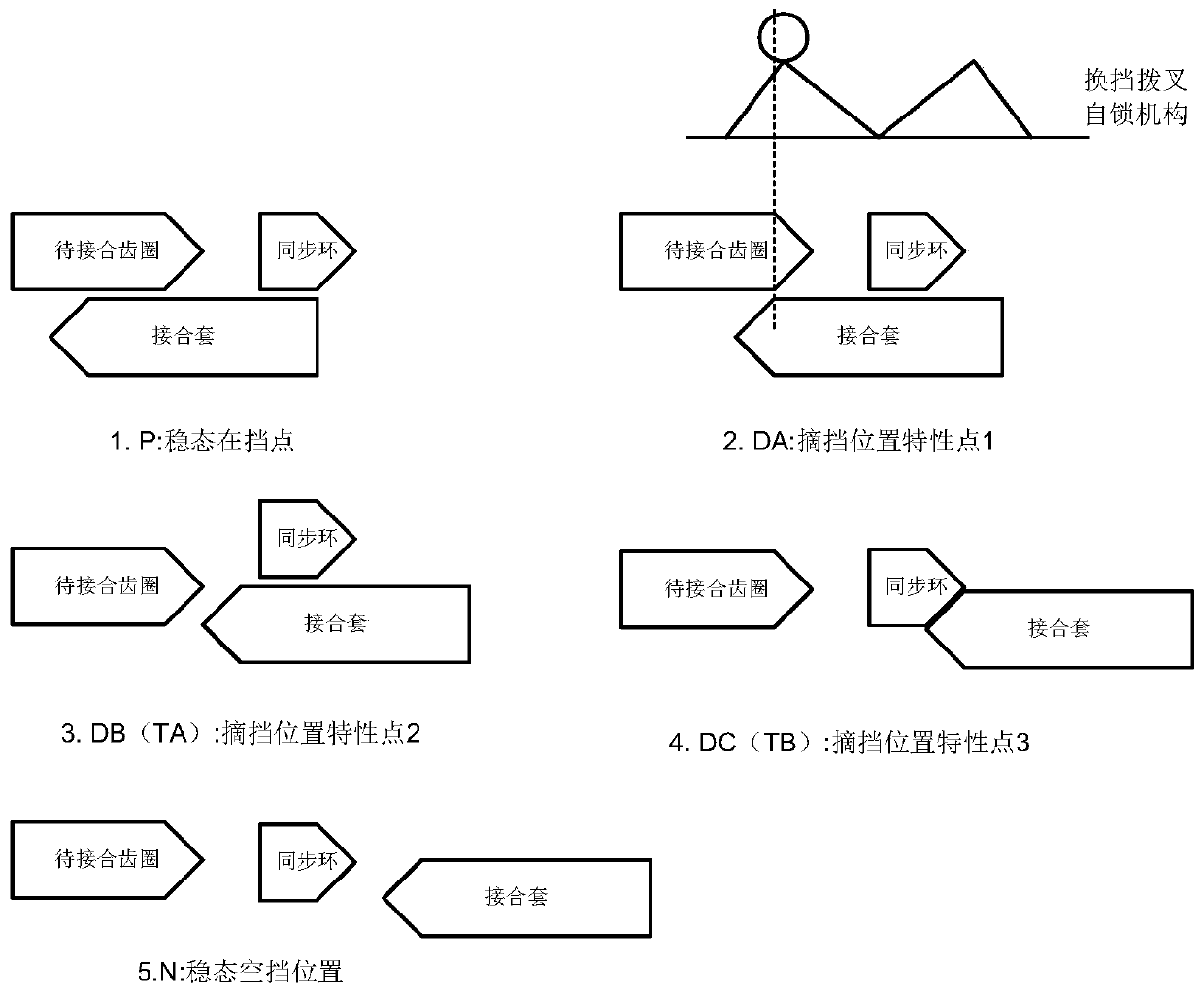

[0035] Such as figure 1 As shown, the single-cone lock ring synchronizer involved in the present invention includes: a ring gear 110 to be engaged, which is integrated with the target gear gear, and the conical surface of the ring gear 110 to be engaged contacts the inner surface of the synchronizer ring 120, and The friction torque is generated on the friction surface to achieve synchronization. After the synchroniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com