Combined type synthetic jet actuator utilizing piezoelectric vibrating diaphragm and two-electrode plasma

A piezoelectric vibration and plasma technology, used in mechanical equipment, circuit components, etc., can solve the problem of high temperature, improve the excitation effect, improve work efficiency, and highlight substantial effects and effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing of description, the present invention will be further described.

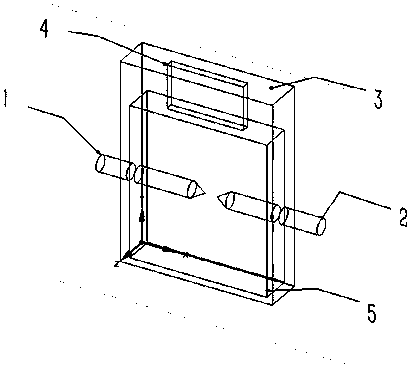

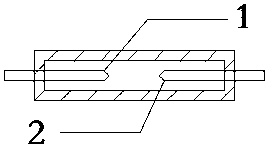

[0021] See attached Figure 1-2 , an implementation example of the present invention using a piezoelectric vibrating film and a two-electrode plasma combined synthetic jet actuator. It includes a rectangular exciter body, a piezoelectric vibrating film 5, a cover plate 3, an outlet slot 4, an ignition positive electrode 1, an ignition negative electrode 2 and an external pulse power supply (not shown). The exciter body includes an exciter cavity, and two sides of the exciter body are provided with a through hole with a diameter of 2mm passing through the exciter body, matching the size of the two electrodes. The exciter cavity has a length of 20 mm, a width of 5 mm, and a height of 20 mm. The exciter cavity and cover plate are made of good insulation and machinable boron nitride ceramics. The size of the cover plate matches the size of the top of the excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com