Curtain wall connecting structure

A technology for connecting structures and curtain walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problems that affect the reuse of aluminum veneers and aluminum profiles, the flexibility is not high, and the operation is complicated, so as to achieve many changes in appearance and convenience Operating procedures, the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

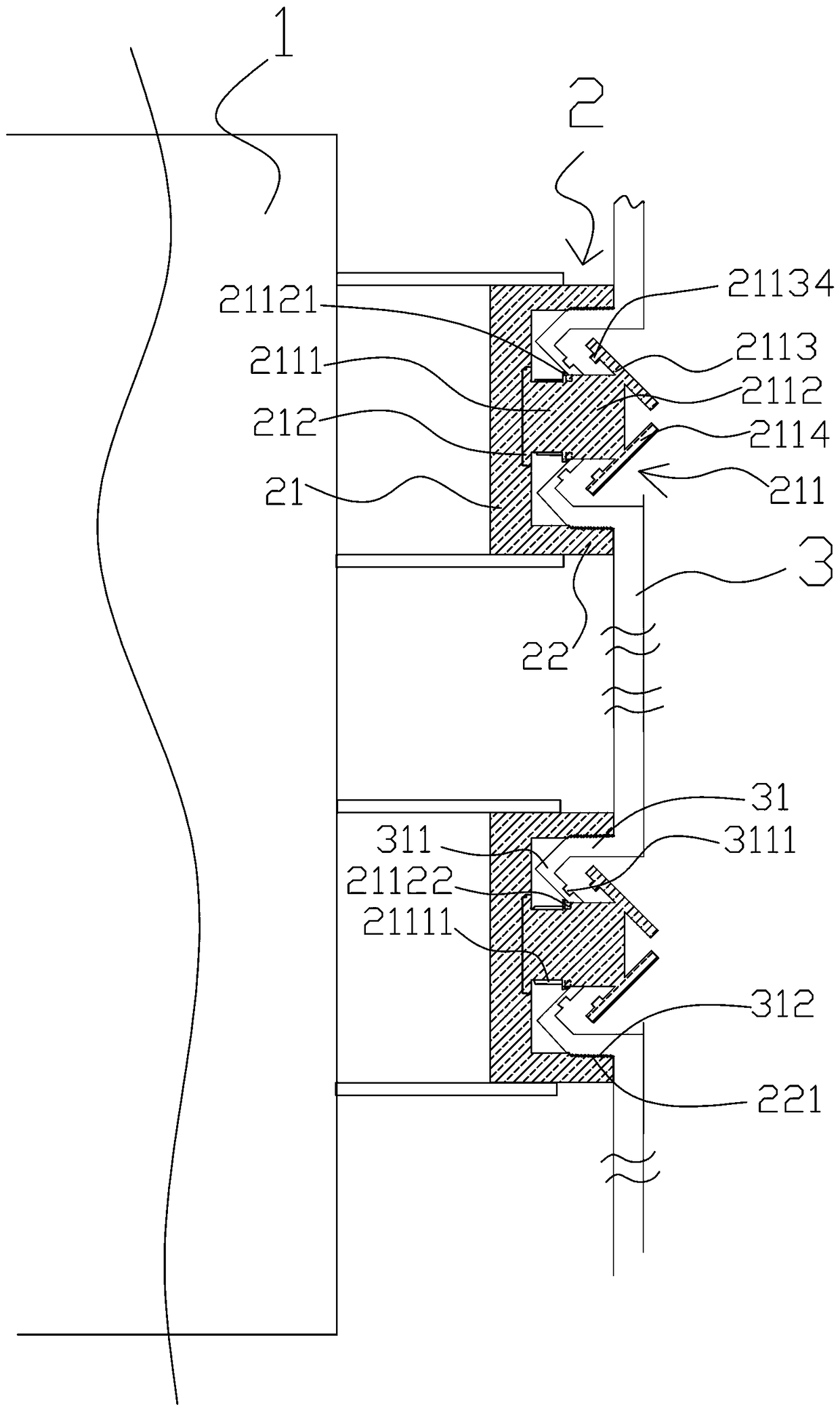

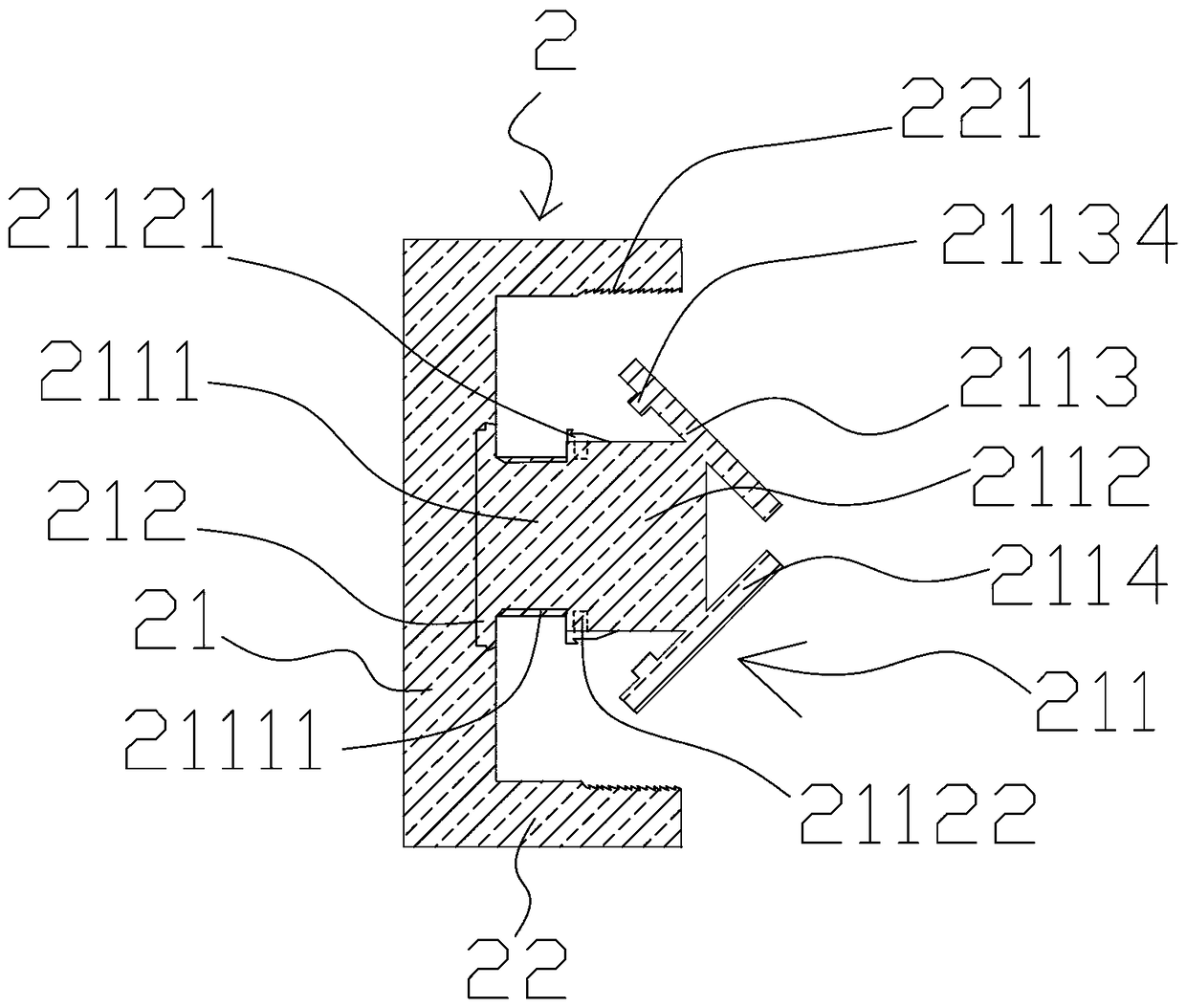

[0024] Such as figure 1 , figure 2 As shown, a curtain wall connection structure provided in this embodiment includes a wall 1, a keel 2 and an aluminum veneer 3, and the keel 2 is connected to the wall 1 and the aluminum veneer 3 through different connection structures respectively. connected, the keel 2 includes a bottom plate 21 and side plates 22 arranged on both sides of the bottom plate 21, the bottom plate 21 is provided with a locking device 211, and the aluminum veneer 3 is engaged with the locking device 211 connected, the locking device 211 includes a fixed base 2111 connected to the bottom plate 21, a telescoping head 2112 socketed on the fixed base 2111, and an upper locking member 2113 and The lower locking member 2114 and the expansion and contraction range of the telescopic head 2112 can be set in different ranges according to different installation requirements. For example, when the telescopic head 2112 is in an extended state, the side away from the bottom...

Embodiment 2

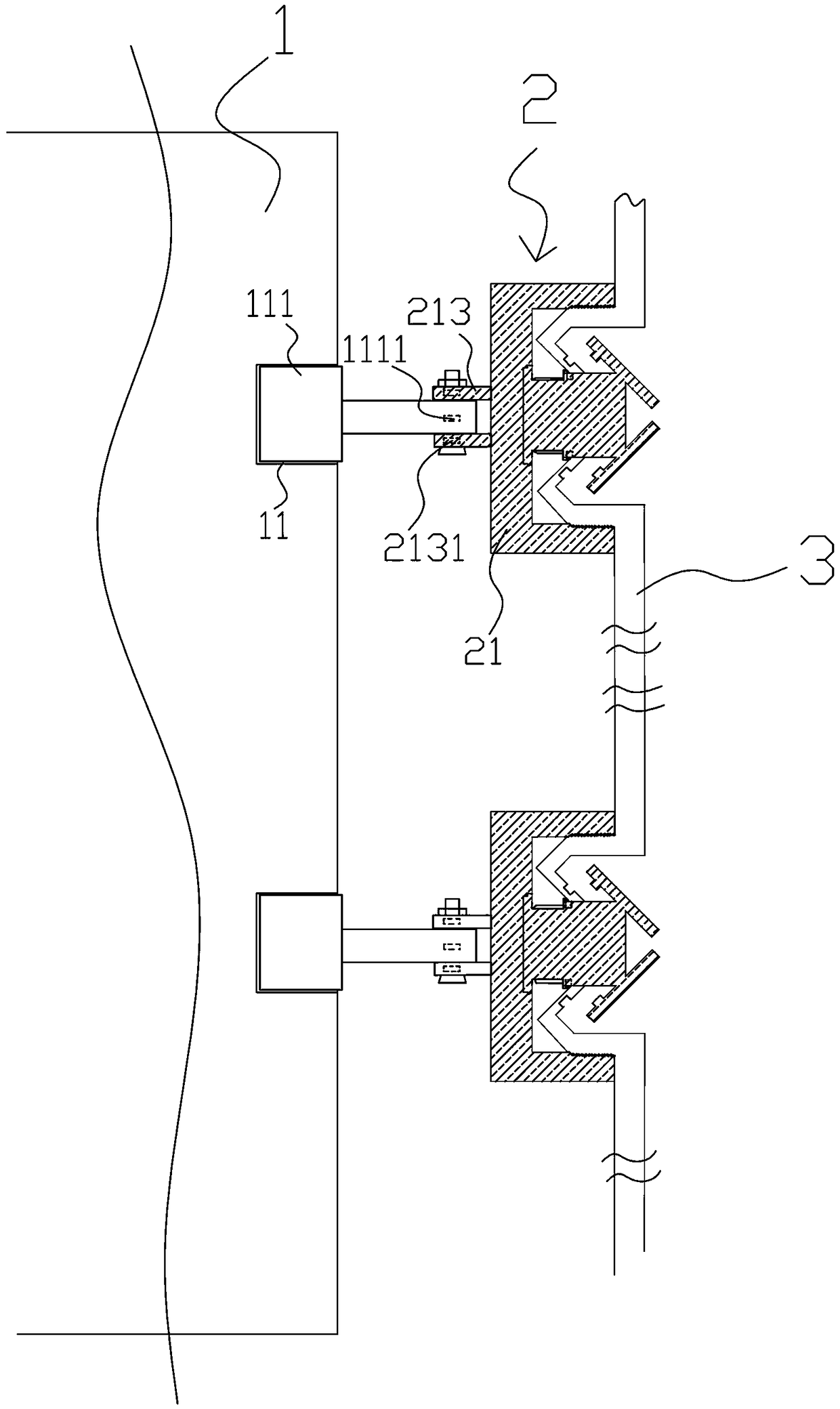

[0034] The difference between this embodiment and Embodiment 1 is that the locking devices 211 are distributed on the bottom plate 21 at intervals. It can save a large part of the material and reduce the cost; under normal circumstances, the aluminum veneer 3 can be stabilized only by locking the two ends of the flanging 31 of the aluminum veneer 3, so the locking devices 211 are distributed at intervals, and the interval distance Determined by the length of the aluminum veneer 3.

[0035] Such as image 3 As shown, the wall body 1 is provided with an indented installation groove 11, and the indented installation groove 11 is provided with a telescopic device 111, and the telescopic end of the telescopic device 111 is connected with the keel 2. The telescopic device 111 is a telescopic cylinder, which can control its telescopic and telescopic length by electrification.

[0036] The telescopic end of the telescopic device 111 is provided with a screw hole 1111 perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com