Novel power cable equipment

A technology for power cables and equipment, applied in the field of new power cable equipment, can solve the problems of inconsistent soil layer density, easy uneven settlement of soil foundation, and tipping of poles, etc., to achieve convenient operation, improve leveling and beating effects, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

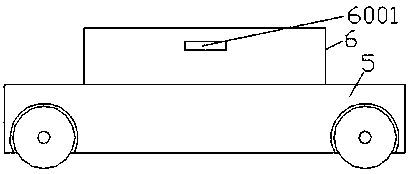

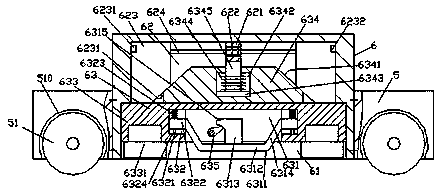

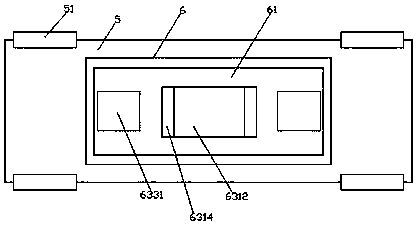

[0017] Such as figure 1 , figure 2 with image 3 As shown, a new type of power cable equipment of the present invention includes a base 5 and a soil conditioner 6 fixedly installed in the base 5, and the bottom surface of the soil conditioner 6 is provided with a first sinker 61, so The inner top wall of the first sinker 61 is communicated with a second sinker 62 extending upwards. The first sinker 61 is slidingly fitted with a lifting block 63 connected to the top of the lifting block 63. A push block 634 that penetrates into the second sinking groove 62 and is connected by sliding fit is fixed, and the left and right sides of the push block 634 are correspondingly provided with a first inclined surface 6341, and the opposite sides of the push block 634 are The inner top wall of the second sinking groove 62 is fixed with a convex end block 621, and the bottom surface of the lifting and sliding block 63 is provided with a third sinking groove 631, and the left and right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com