Underwater wet-method repairing device and method for concrete pile defects

A technology of concrete piles and repair methods, which is applied in the repair of infrastructure, construction, infrastructure engineering and other directions, can solve problems such as low efficiency and large amount of engineering, and achieve the effects of high repair efficiency, high adaptability and saving installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

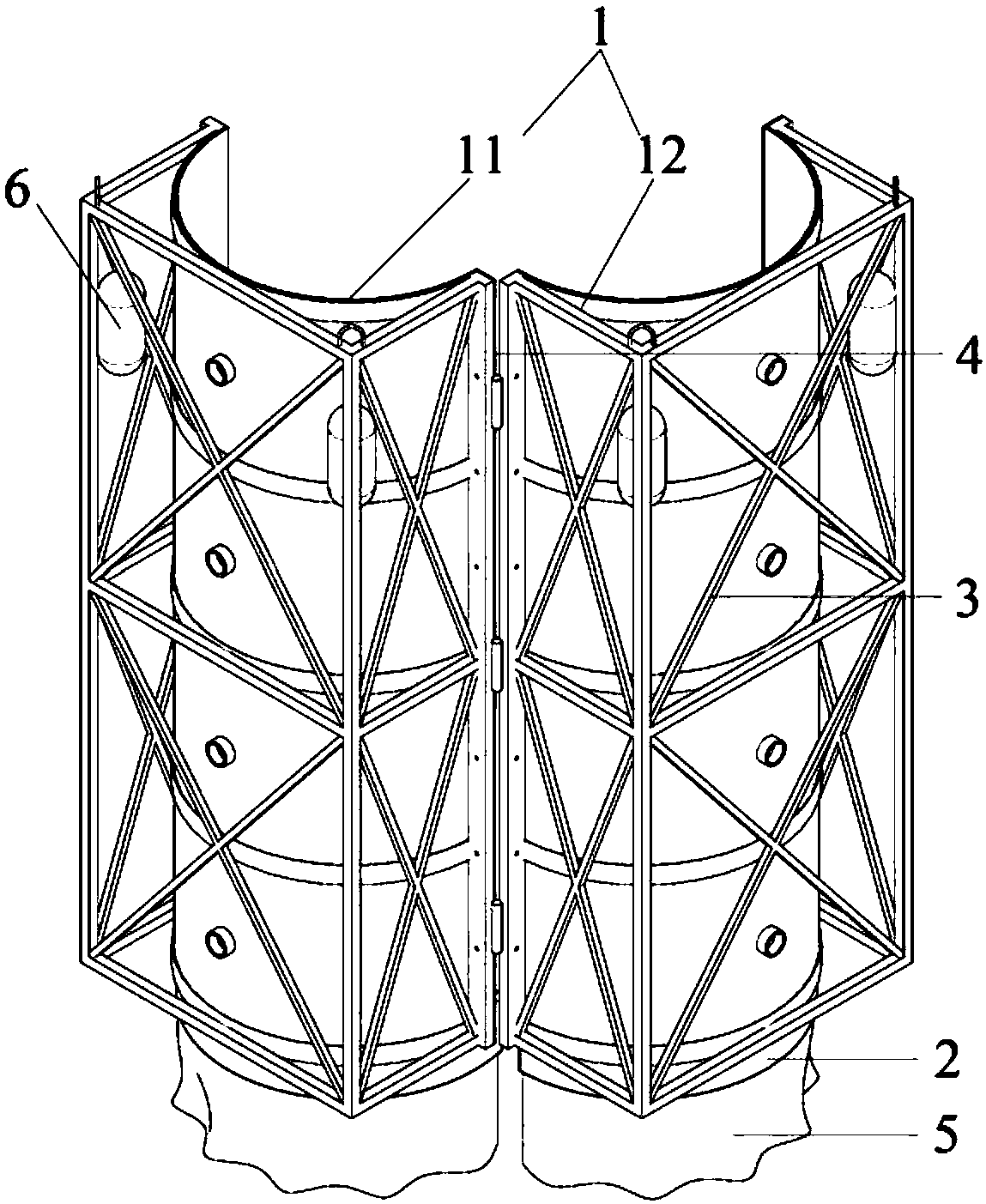

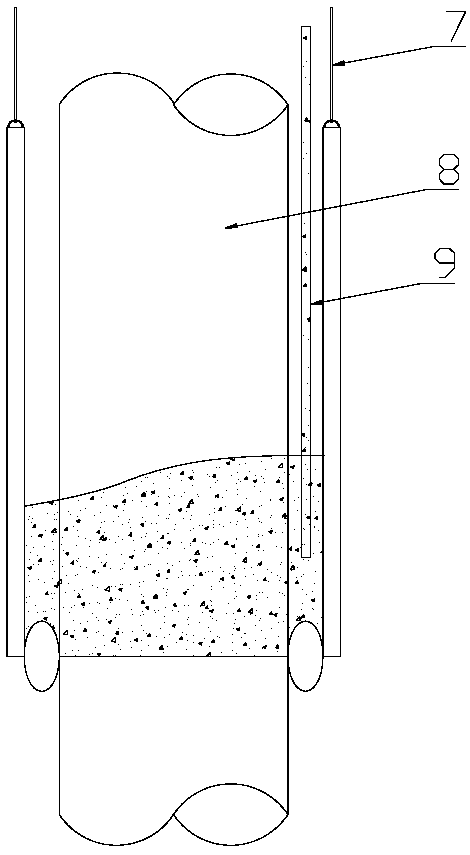

[0031] Such as figure 1 with figure 2 As shown, the present invention provides a concrete pile defect underwater wet repair device, comprising a side form 1 that surrounds the concrete pile 8 and a bottom form 2 that seals between the concrete pile 8 and the bottom of the side form 1, said The bottom mold 2 is arranged at the bottom of the side mold 1 . The side form 1 forms a formwork around the concrete pile 8 to be repaired, a certain gap is reserved between the side form 1 and the concrete pile 8, the bottom form 2 seals the bottom gap between the concrete pile 8 and the side form 1, and then the repair material is poured into the side form 1 and the concrete pile 8, after the repairing material is solidified, the repairing device can be disassembled and reused.

[0032] Specifically, the side mold 1 includes a first side mold 11 and a second side mold 12, and the first side mold 11 and the second side mold 12 are made of light and hard materials. The frame 3 for reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com