A physical pressing process treatment system for the production of juniper berry essential oil

The technology of a juniper berry essential oil and a processing system is applied in the field of a physical pressing process treatment system for the production of juniper berry essential oil, and can solve the problems of difficult pressing and insufficient pressing, and achieve the effects of preventing accumulation, simple structure and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

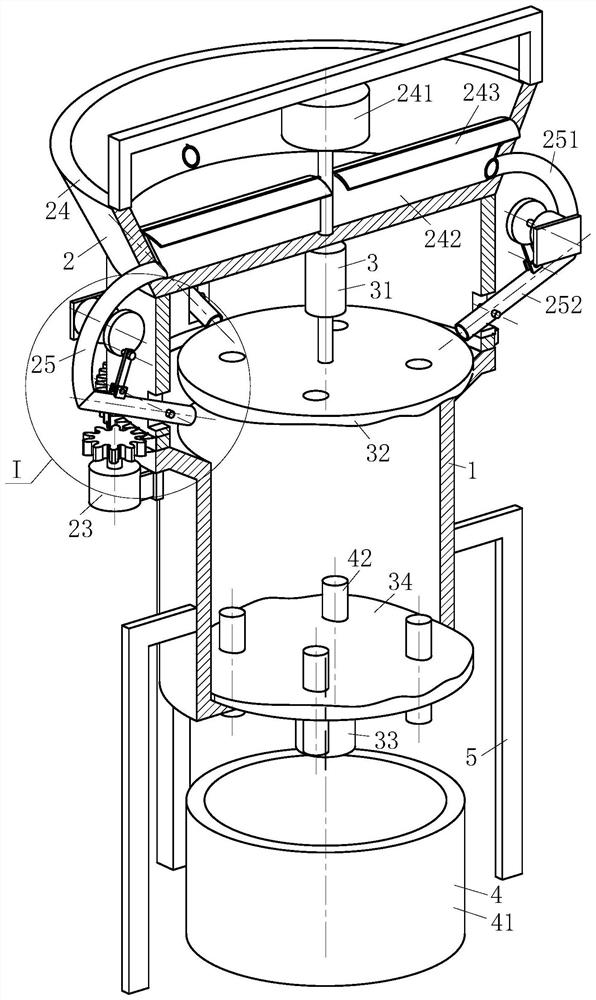

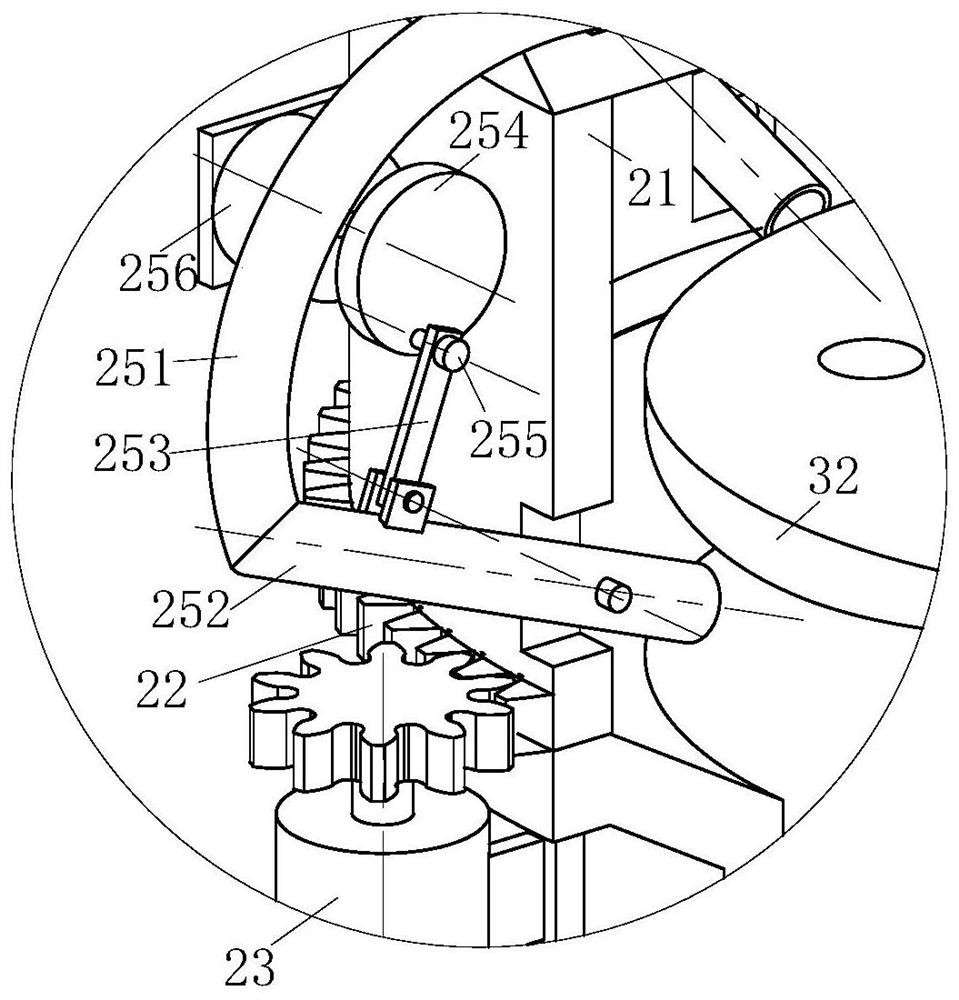

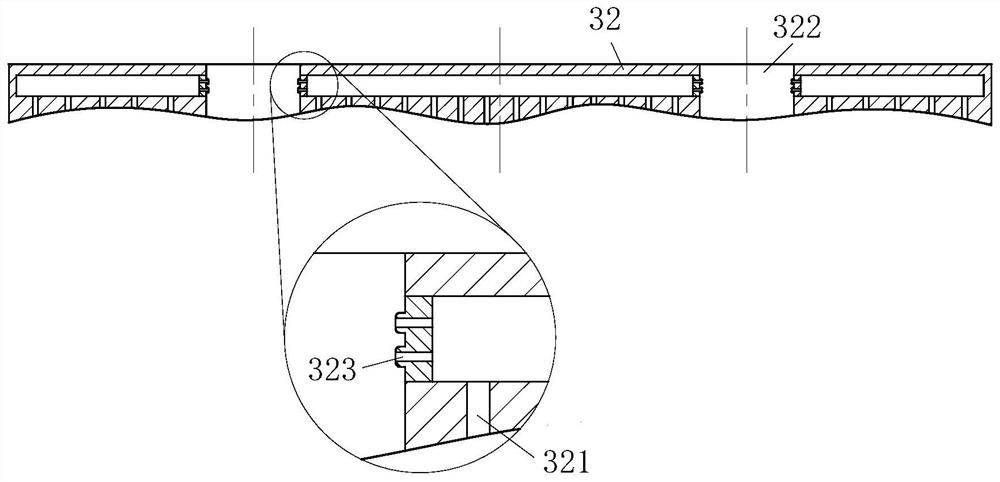

[0028]As an embodiment of the present invention, the squeeze module 3 includes a first telescopic rod 31, a first squeeze disc 32, a second telescopic rod 33 and a second squeeze disc 34; the first telescopic rod 31 is fixedly mounted on the housing The upper end of the body 21; the lower end of the first telescopic rod 31 is fixedly connected to the first squeeze plate 32; the first squeeze plate 32 is provided with a cavity; the bottom of the first squeeze plate 32 is provided with a plurality of liquid outlets 321; the first squeeze plate 32 is provided with a through hole 322 corresponding to the outlet pipe 42; the inside of the through hole 322 is provided with a conduit 323 corresponding to the communication hole 422; the conduit 323 is used to open the valve 423, And export the squeezed essential oil; the first squeeze plate 32 falls, so that the liquid outlet pipe 42 penetrates the through hole 322 provided by the first squeeze plate 32, and the valve 423 is opened by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com