Pulp composition, environment-friendly duster cloth preparation method and environment-friendly duster cloth

A technology of composition and slurry, applied in cleaning equipment, application, cleaning machinery, etc., can solve the problems of discarding, inability to remove stains, single function, etc., and achieve the effect of strong water absorption, easy degradation, and good water and oil absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

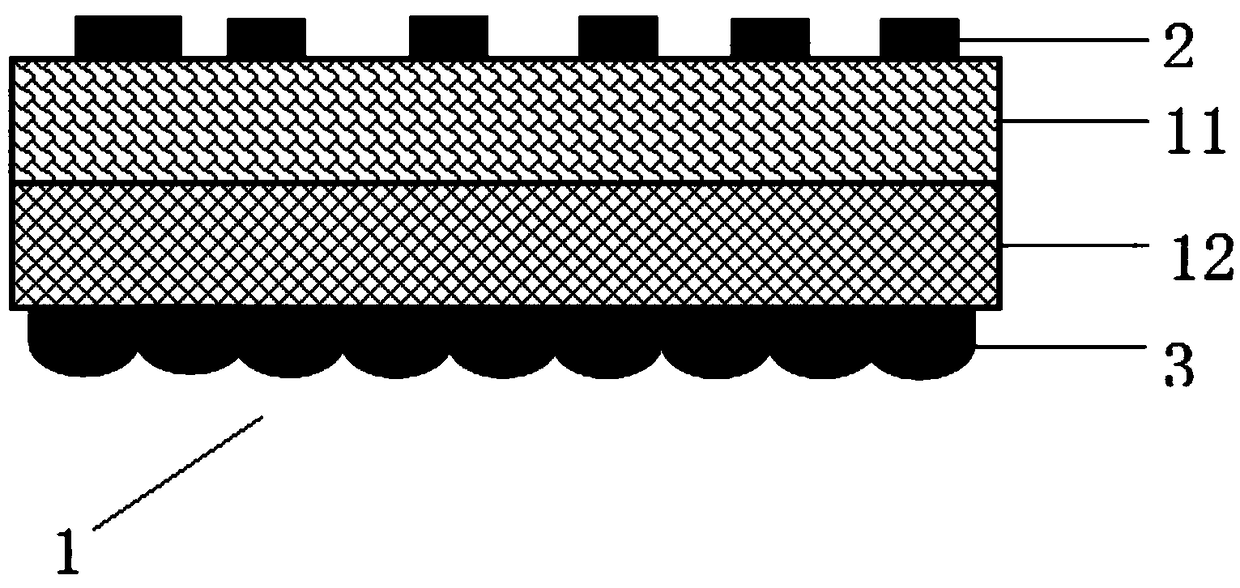

[0024] An environment-friendly rag, the environment-friendly rag 1 at least includes a surface layer 11 and a bottom layer 12, the surface layer 11 is a slurry composition, that is, a wood pulp fiber yarn and a composite layer of reinforcing fibers, and the bottom layer 12 is a slurry composition , which is a mixed layer of wood pulp fiber yarn and reinforcing fiber, the surface layer 11 is provided with a protruding structure 1, and the bottom layer is provided with a protruding structure 2 3, and the surface layer 11 and the bottom layer 12 are both provided with Irregular pores. The first raised structure 2 is rhombus or rectangular, and the second raised structure 3 is alternately arranged semicircular raised structures.

[0025] A slurry composition comprising at least the following components by weight: 70 parts of wood pulp, 5 parts of cotton fiber, 4 parts of wood fiber, 3 parts of hemp fiber, 15 parts of alkali, and 8 parts of carbon disulfide , 200 parts of sodium s...

Embodiment 2

[0032] An environment-friendly rag, the environment-friendly rag 1 at least includes a surface layer 11 and a bottom layer 12, the surface layer 11 is a slurry composition, that is, a wood pulp fiber yarn and a composite layer of reinforcing fibers, and the bottom layer 12 is a slurry composition , which is a mixed layer of wood pulp fiber yarn and reinforcing fiber, the surface layer 11 is provided with a protruding structure 1, and the bottom layer is provided with a protruding structure 2 3, and the surface layer 11 and the bottom layer 12 are both provided with Irregular pores. The first raised structure 2 is rhombus or rectangular, and the second raised structure 3 is alternately arranged semicircular raised structures.

[0033] A kind of slurry composition, described slurry composition is to at least comprise the component wood pulp 75 parts of following parts by weight, 6 parts of cotton fiber, 5 parts of wood fiber, 4 parts of hemp fiber, 17 parts of alkali, 9 parts of...

Embodiment 3

[0040] An environment-friendly rag, the environment-friendly rag 1 at least includes a surface layer 11 and a bottom layer 12, the surface layer 11 is a slurry composition, that is, a wood pulp fiber yarn and a composite layer of reinforcing fibers, and the bottom layer 12 is a slurry composition , which is a mixed layer of wood pulp fiber yarn and reinforcing fiber, the surface layer 11 is provided with a protruding structure 1, and the bottom layer is provided with a protruding structure 2 3, and the surface layer 11 and the bottom layer 12 are both provided with Irregular pores. The first raised structure 2 is rhombus or rectangular, and the second raised structure 3 is alternately arranged semicircular raised structures.

[0041] A slurry composition, the slurry composition at least includes the following components by weight: 80 parts of wood pulp, 10 parts of cotton fiber, 6 parts of wood fiber, 4 parts of hemp fiber, 20 parts of alkali, 9 parts of carbon disulfide , 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com