Slitter Inflatable Rewinding Chuck

An inflatable and slitting machine technology, applied in the field of rolling fixtures, can solve the problems of manufacturing cost, high maintenance cost, large overall structure volume, increased control cost, etc., to reduce energy consumption, simple overall structure, and save manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

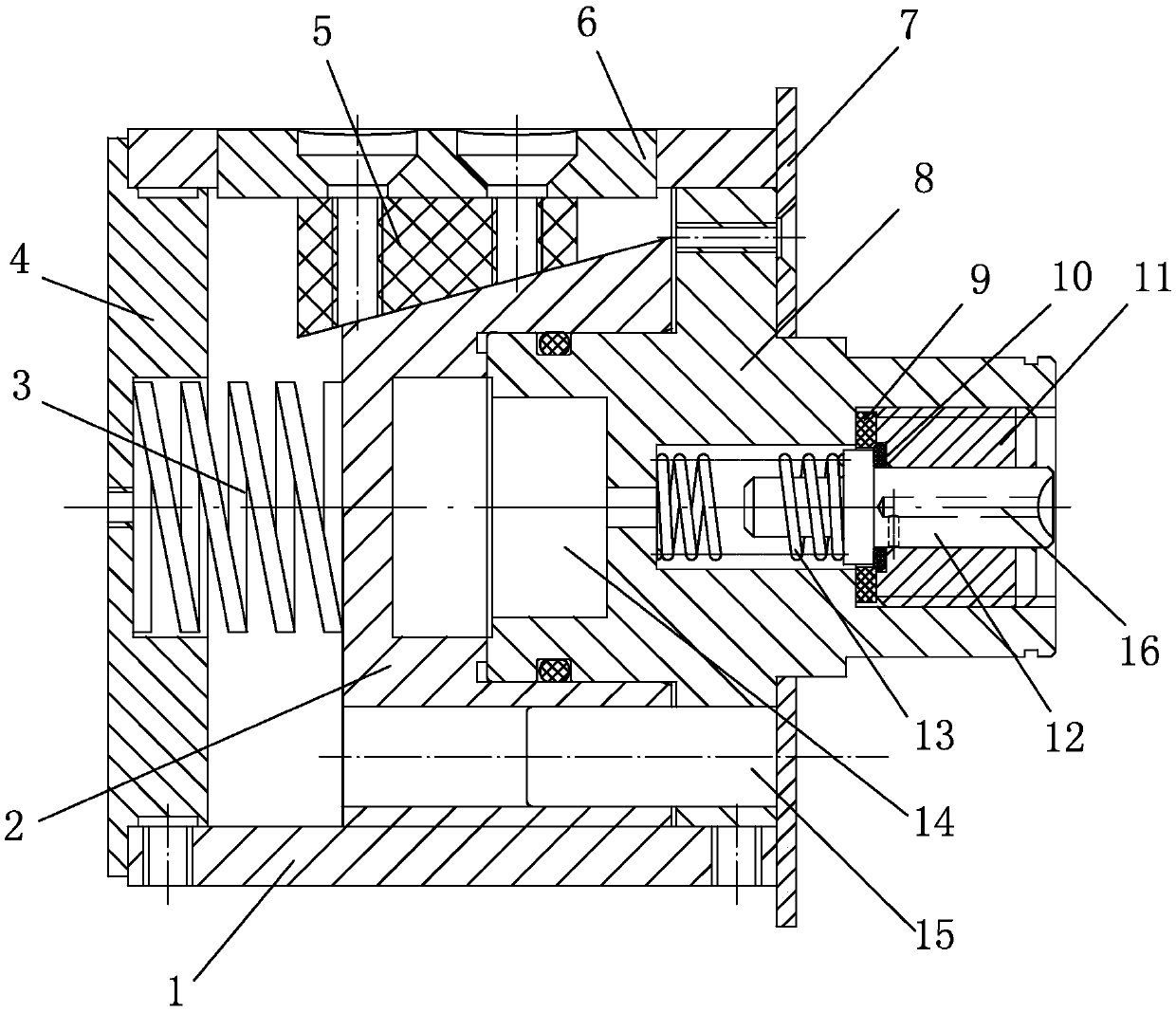

[0014] Embodiment: The air-expandable rewinding chuck of the slitting machine of the present invention, as attached figure 1 As shown, it includes an outer casing 1, an end shaft 8, a steel core 2 and several tension blocks 6.

[0015] The outer casing 1 is a circular cylindrical structure with a cavity inside, the left end is closed, and the right end is open;

[0016] The end shaft 8 is set at the open end of the outer casing 1; the end shaft 8 partly extends into the outer casing 1, and the end is a stepped structure with end shrinkage, and a guide shaft 15 is axially arranged on the side wall of the step portion; the end shaft 8 is axially Set three-stage stepped holes, the diameters of the three stages are gradually smaller, the diameter of the tail section connecting the cavity 14 is the smallest, the air nozzle 12 is set in the middle hole, the washer 9 and the locking sleeve 11 of the compression washer 9 are set in the right hole, and the locking sleeve 11 is locked. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com