Combined type robot car chassis

A robot and combined technology, applied in the direction of motor vehicles, vehicle parts, substructure, etc., can solve the problems of cumbersome and complex design, and achieve the effects of convenient teaching, reasonable structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

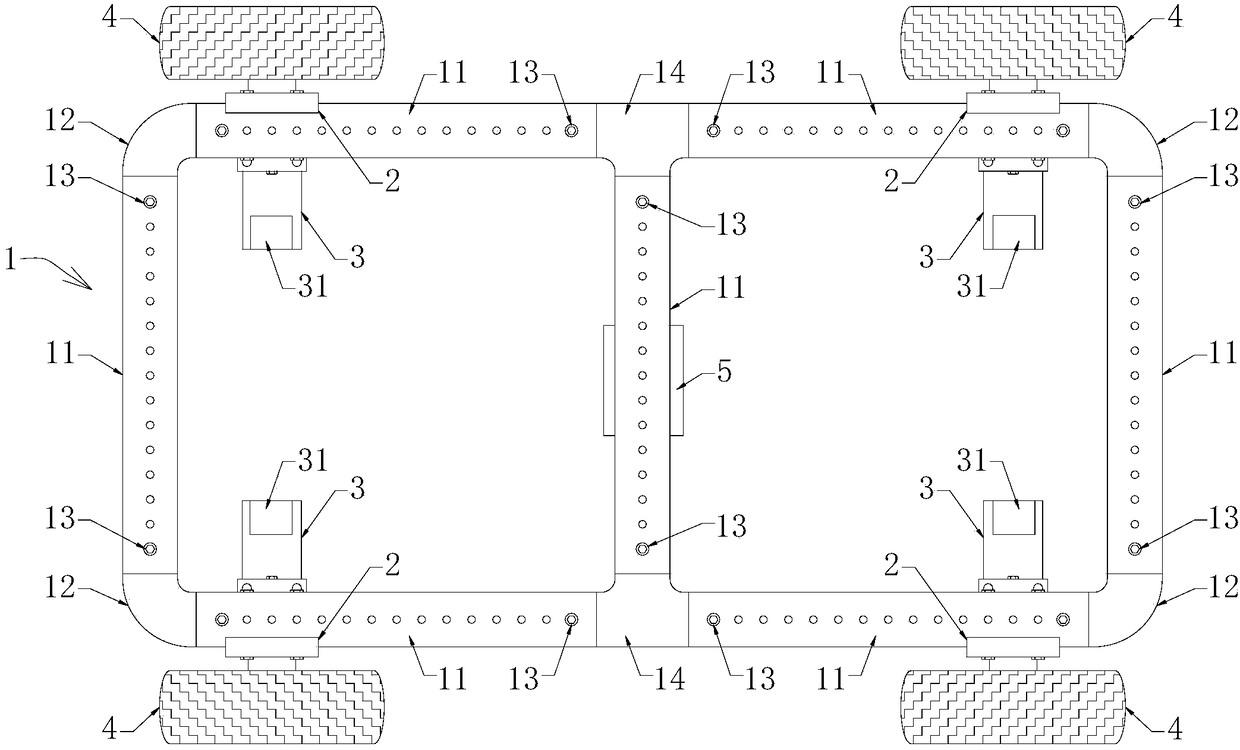

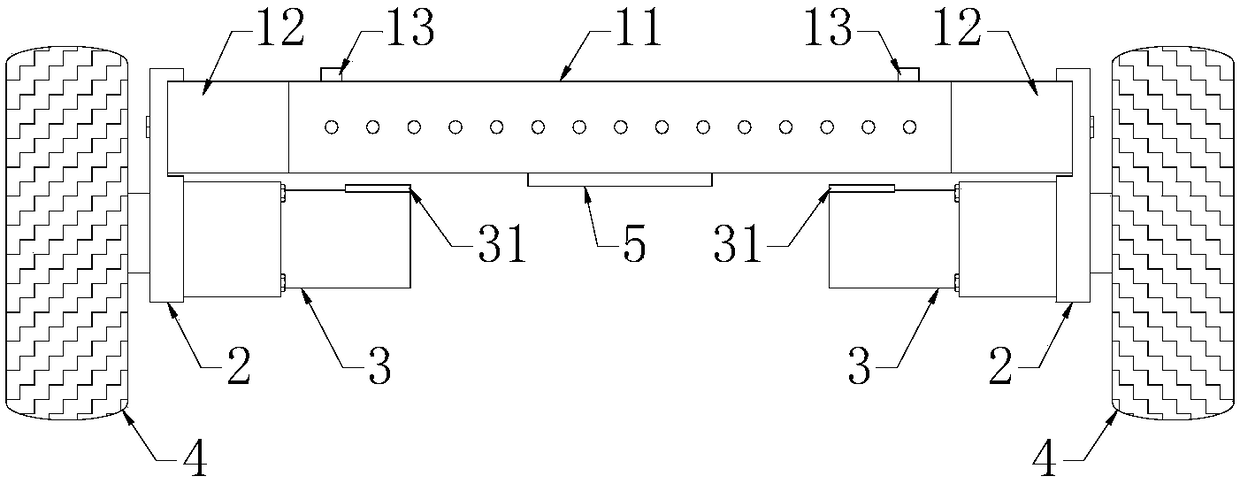

[0027] refer to figure 1 and figure 2 , the present invention implements a combined robot trolley chassis, including a chassis frame 1, a bracket 2, a motor 3 and wheels 4, and the chassis frame 1 is composed of several aluminum square tubes 11, a plurality of double-head connectors 12 and multiple A rectangular frame structure assembled from four fasteners 13, the double-head connector 12 is a 90° connector, and the chassis frame 1 also includes a three-head connector 14, and the three-head connector 14 is T-shaped structure, the two long sides of the chassis frame 1 are composed of two aluminum square tubes 11 and the three-head connector 14 connecting the two aluminum square tubes 11, and the three-head connector 14 on the two long sides An aluminum square tube 11 is connected, and a double-head connector 12 is connected to both ends of the two long sides, and the double-head connectors 12 corresponding to the two long sides are connected by an aluminum square tube 11. T...

Embodiment 2

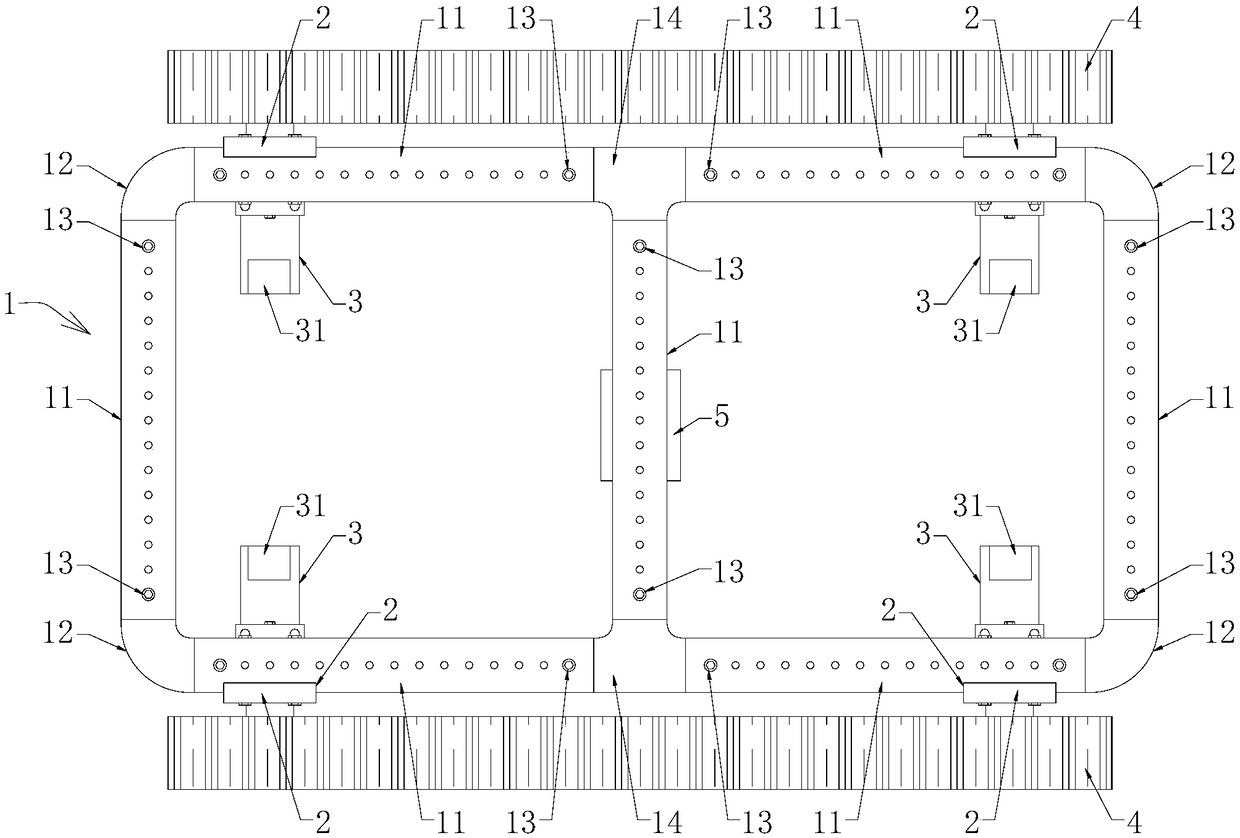

[0029] refer to image 3 and Figure 4 , the present invention implements a combined robot trolley chassis, including a chassis frame 1, a bracket 2, a motor 3 and wheels 4, and the chassis frame 1 is composed of several aluminum square tubes 11, a plurality of double-head connectors 12 and multiple A rectangular frame structure assembled from four fasteners 13, the double-head connector 12 is a 90° connector, and the chassis frame 1 also includes a three-head connector 14, and the three-head connector 14 is T-shaped structure, the two long sides of the chassis frame 1 are composed of two aluminum square tubes 11 and the three-head connector 14 connecting the two aluminum square tubes 11, and the three-head connector 14 on the two long sides An aluminum square tube 11 is connected, and a double-head connector 12 is connected to both ends of the two long sides, and the double-head connectors 12 corresponding to the two long sides are connected by an aluminum square tube 11. T...

Embodiment 3

[0031] refer to Figure 5 , the present invention implements a combined robot trolley chassis, including a chassis frame 1, a bracket 2, a motor 3 and wheels 4, and the chassis frame 1 is composed of several aluminum square tubes 11, a plurality of double-head connectors 12 and multiple A hexagonal frame structure assembled from four fasteners 13, the double-head connector 12 is an obtuse angle connector, and the chassis frame 1 also includes a short square tube 15, and each aluminum tube on the chassis frame 1 Both ends of the square tube 11 are connected with a double-head connector 12, and a short square tube 15 is connected between the double-head connectors 12 at the ends of two adjacent aluminum square tubes 11, and the short square tube 15 is connected to the aluminum square tube. The tubes 11 are only different in length, and the joints between the double-headed connectors 12, the aluminum square tube 11 and the short square tube 15 are locked and connected by fastener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com