Ultrathin tempered glass automatic drilling machine tool based on binocular camera shooting and recognition

A binocular camera, tempered glass technology, applied in image communication, color TV parts, TV system parts and other directions, can solve the problems of low degree of automation, poor product quality stability, parts collapse, high breakage rate, etc. To achieve stable product quality, reduce processing auxiliary time, and avoid the effects of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

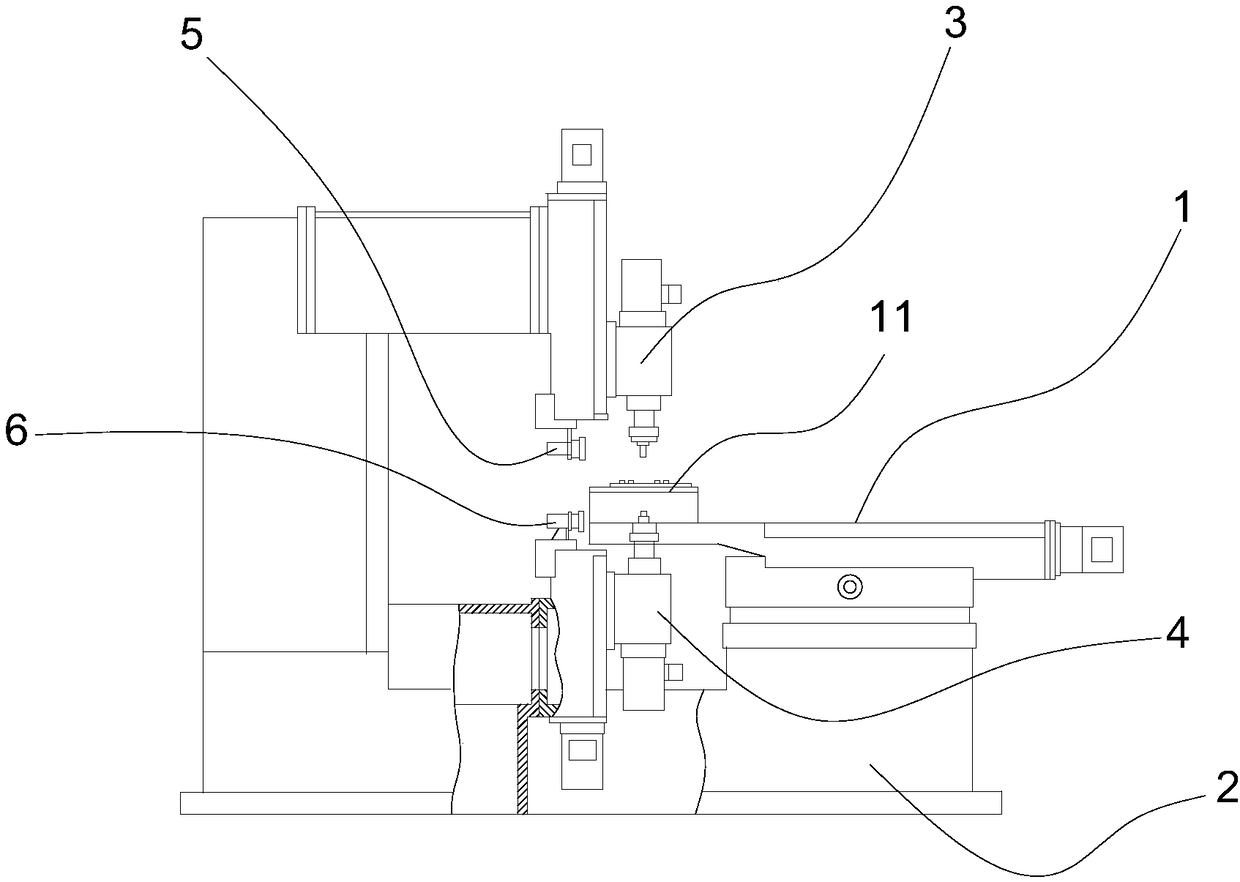

Image

Examples

Embodiment 1

[0050] For the convenience of understanding, the working process of the ultra-thin tempered glass automatic drilling machine tool based on binocular camera recognition of the present invention is briefly described now.

[0051] Take the processing of a workpiece with a thickness of 0.5mm as an example; the specific processing steps are as follows:

[0052] 1. Install the workpiece horizontally on the upper surface, select and install two drill bits 10 of the same specification on the first servo-driven spindle system 3 and the second servo-driven spindle system 4 .

[0053] 2. Reset the system, the two-dimensional working platform 1 moves to translate the processed parts to the correct drilling position; the first servo-driven spindle system 3 and the second servo-driven spindle system 4 reset along the Z direction, and the drill bit 10 moves to the initial processing position ;

[0054] 3. Collect the current profile image information of the drill bit 10 through the first ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com