Quick bearing disassembly device

A bearing and U-shaped technology, which is applied in the field of rapid disassembly of bearings, can solve the problems of small number of claws, damage to the contact end surface of the bearing, and outward slipping of claws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

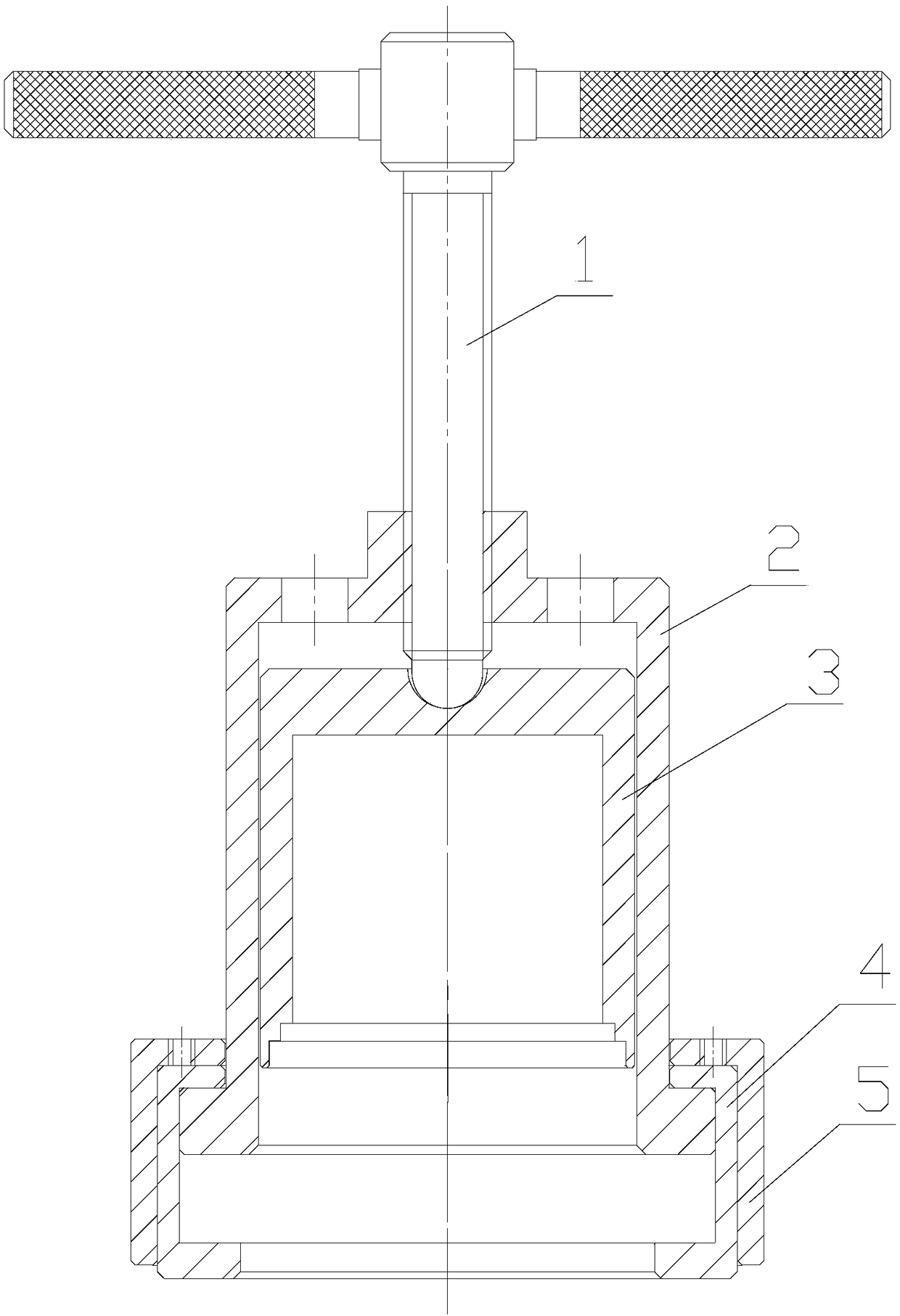

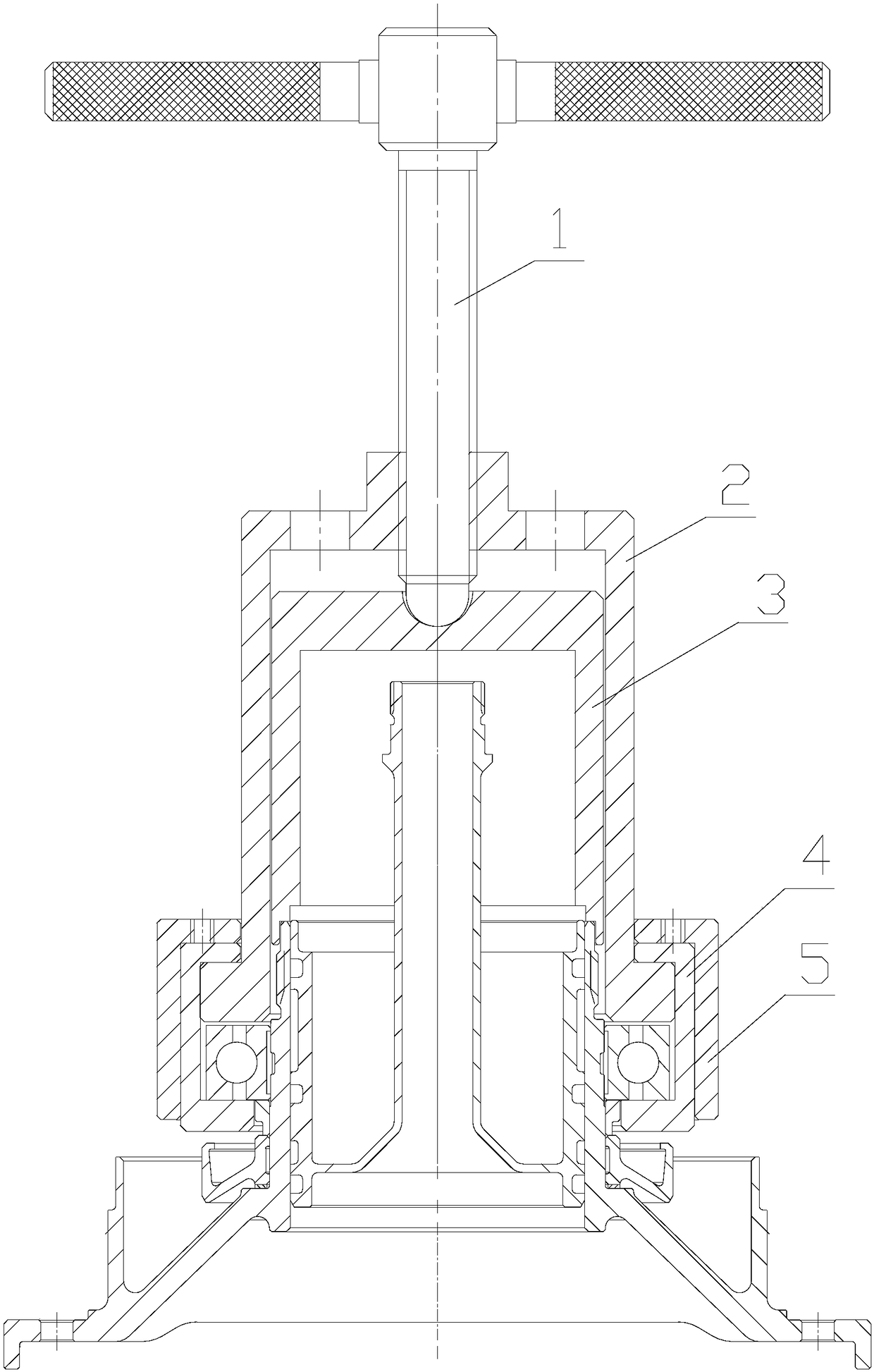

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to figure 1 , figure 2 .

[0015] figure 2 Shown is a diagram of the use method of a quick disassembly bearing device of the present invention. The device comprises a push rod 1, a puller plate 2, a spacer 3, a U-shaped half-pull ring 4, and a pull ring clamp ring 5. The method of use is to first place the spacer 3 on the end face of the rotor shaft journal, insert the puller 2 onto the block 3, and then clamp the U-shaped half-open ring 4 between the lower end face of the bearing and the upper end face of the puller 2, Then use the puller clamp ring 5 to be inserted into the U-shaped half-drawn ring 4 to play the role of tightening the U-shaped half-drawn ring 4, and finally the push rod 1 is screwed into the threaded hole of the puller 2, and kept Rotating at a constant speed, along with the tightening of the ejector rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com