Elbow pipe processing technology

A processing technology and pipe bending technology, which is applied in the field of pipe bending processing technology, can solve the problems of affecting product production efficiency, inaccurate clamping and positioning, complicated procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

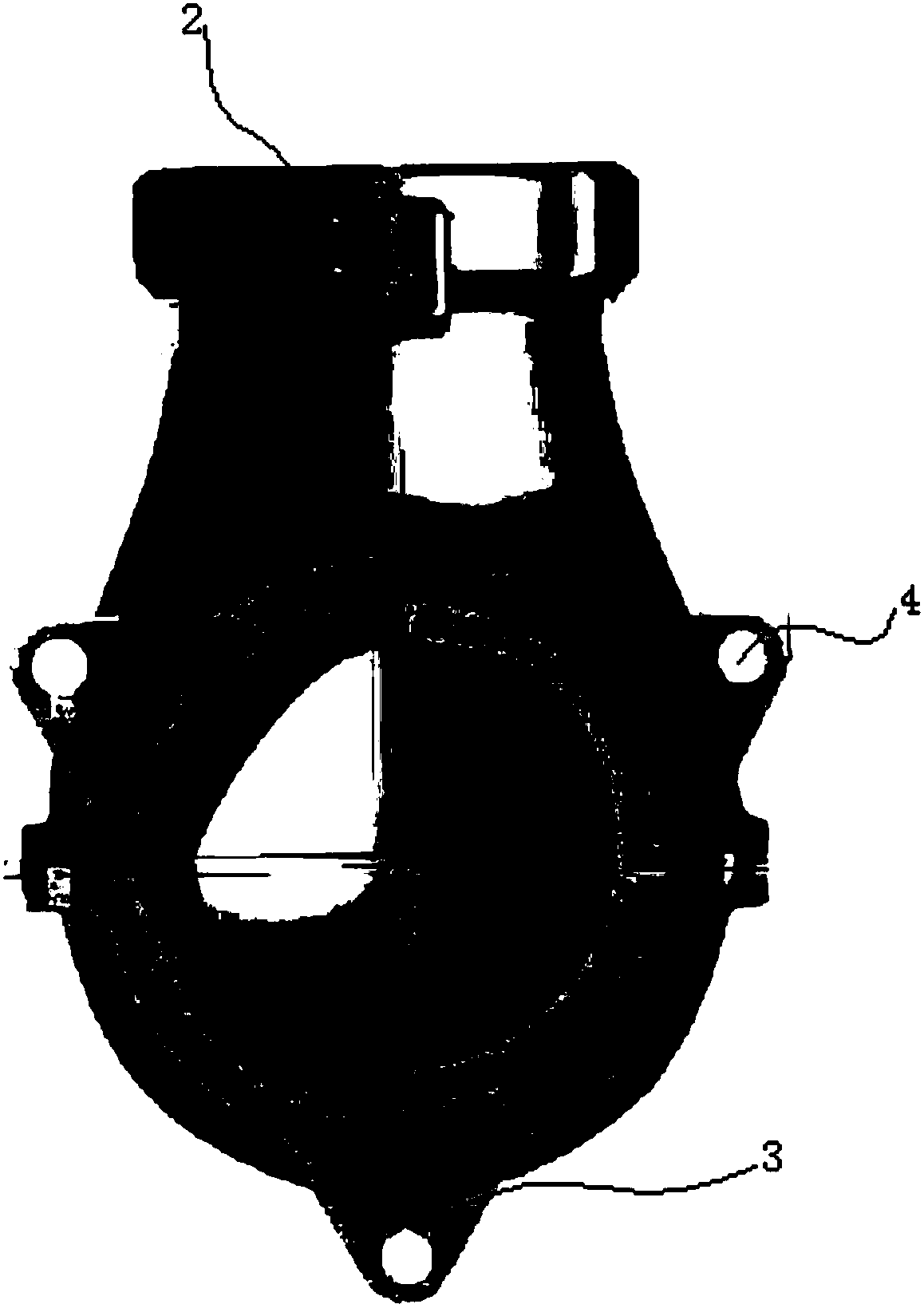

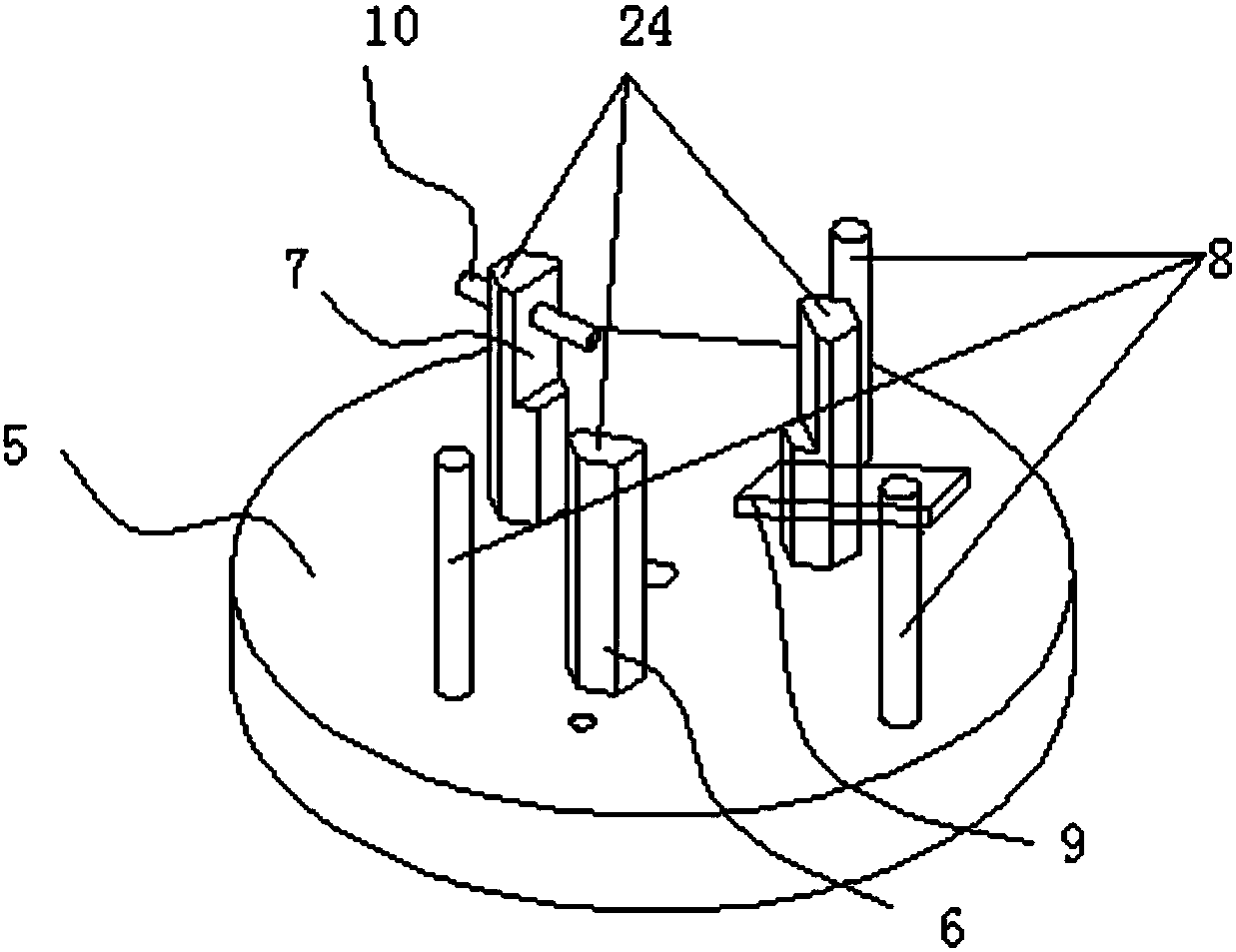

[0021] Such as Figure 1 to Figure 5 As shown, a pipe bending process is used to process a first nozzle 1 and a second nozzle 2, and the first nozzle 1 is provided with a flange 3, and the edge of the first nozzle 1 is higher than The flange 3, and the elbow with the axis of the first nozzle 1 and the axis of the second nozzle 2 perpendicular to each other, comprises the following steps:

[0022] Step 1: Fix the elbow on the outer circle of the first nozzle 2 on the first fixture;

[0023] Step 2: Fix the first nozzle 2 of the elbow to the inner circle of the second nozzle 3 on the second fixture;

[0024] Step 3: Fix the elbow on the third fixture, and drill the hole 4 on the flange 3.

[0025] Use the flange 3 as the positioning on the first fixture, first process the outer circle of the first nozzle 1 with the flange installed, and then use the positioning ring 13 on the second fixture to position the first nozzle of the elbow Process the outer circle of the second nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com