Venturi mixer with porous orifice plate for promoting mixing effect

A technology of venturi mixer and perforated orifice plate, which is applied in the directions of fluid mixer, mixer, chemical instrument and method, can solve the problems of low mixing efficiency, uneven mixing, and inability of fluid to flow, and achieve the effect of promoting mixing , to avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

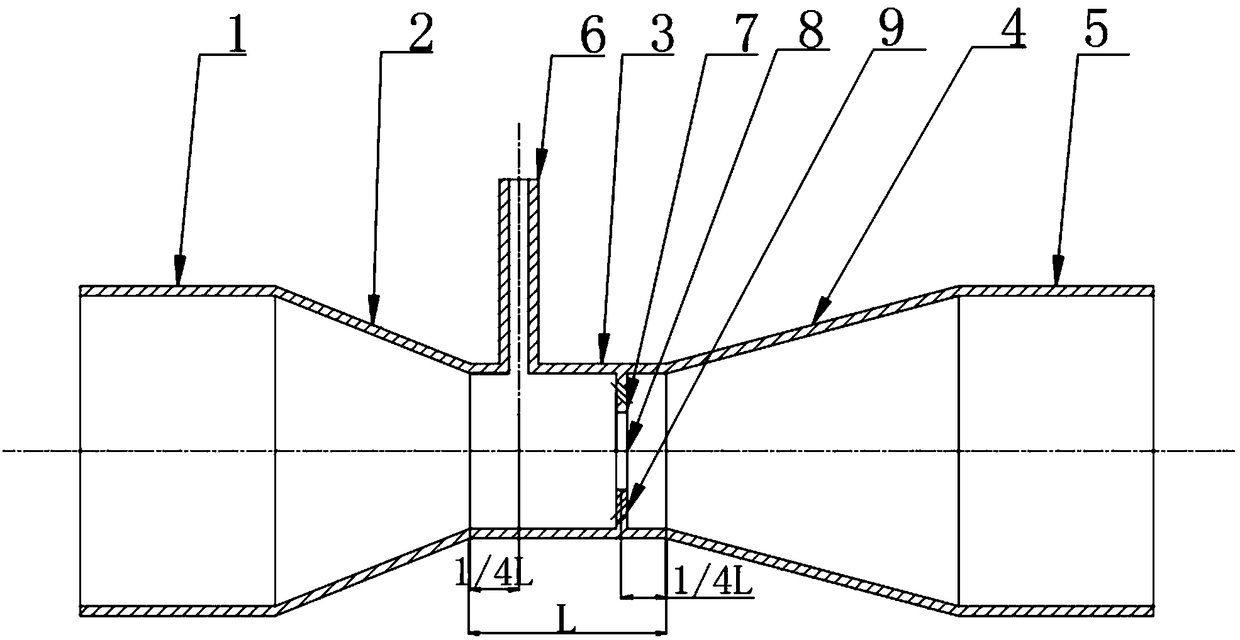

[0020] Such as figure 1 As shown, a Venturi mixer with a porous orifice plate to promote the mixing effect, including the main flow fluid inflow pipeline 1, the main flow fluid constriction section 2, the main flow fluid throat pipeline 3, the main flow fluid diffusion section 4 and the main flow fluid outflow pipeline connected in sequence 5 and the introduction pipe 6 arranged at the upper end of the main flow fluid throat pipe 3 and connected thereto; it is characterized in that: the inner wall of the mainstream fluid throat pipe 3 is welded with a porous orifice plate 7; the porous orifice plate 7 is arranged at the main flow fluid throat Inside pipeline 3.

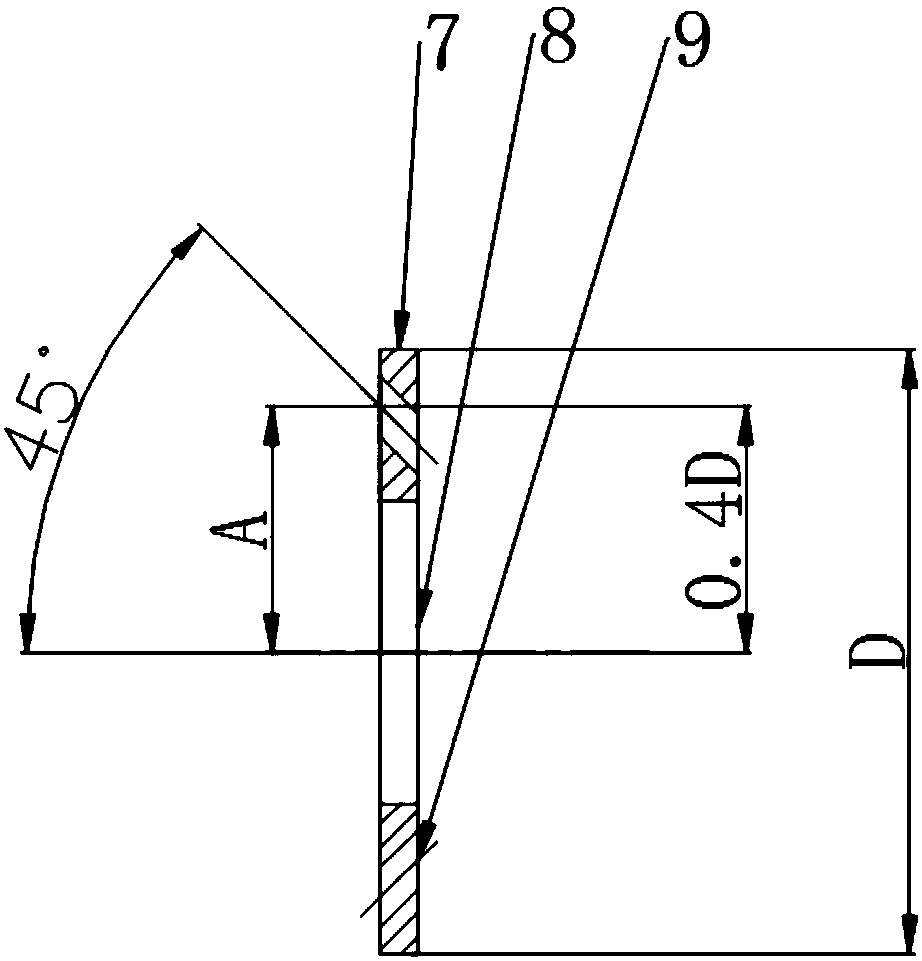

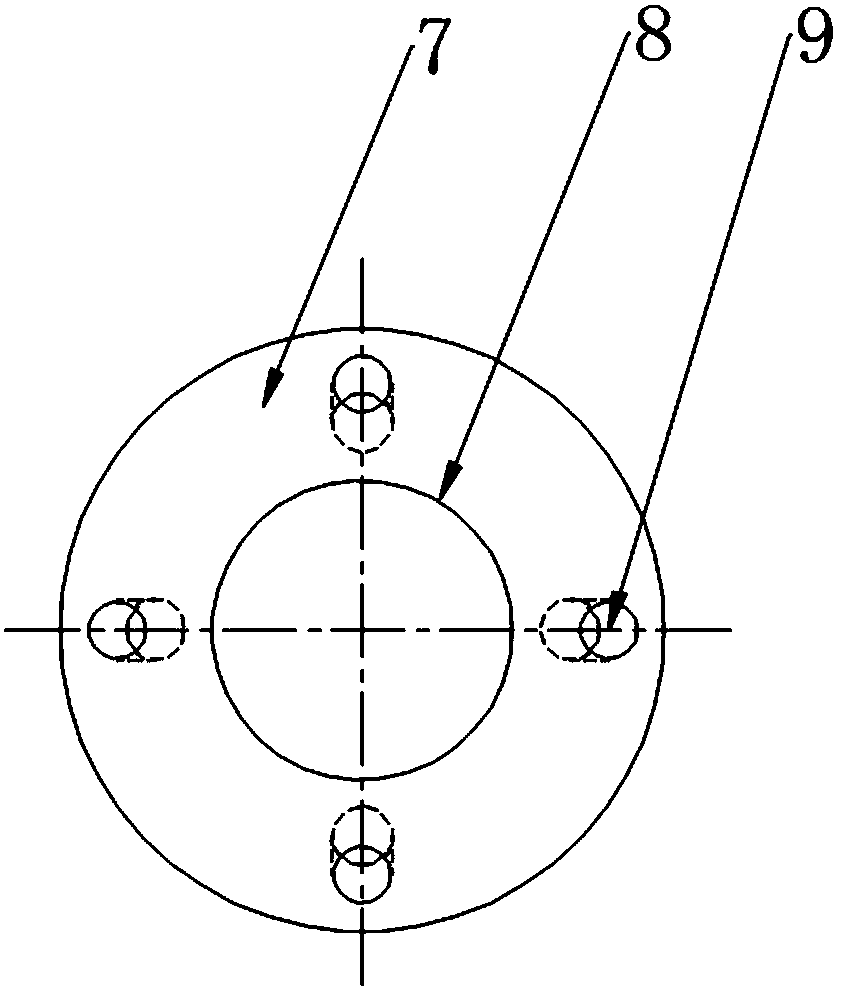

[0021] As a preferred embodiment of the present invention, the Venturi mixer whose porous orifice promotes the mixing effect, such as figure 2 with image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com