Method for preparing shiitake mushrooms with high rehydration property by combined drying of pulsating vacuum radio frequency and microwave

A technology of combined drying and pulsating vacuum, applied in the direction of bacteria used in food preparation, food drying, food ingredients as antimicrobial preservation, etc., can solve problems such as product quality decline, crusting, uneven drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

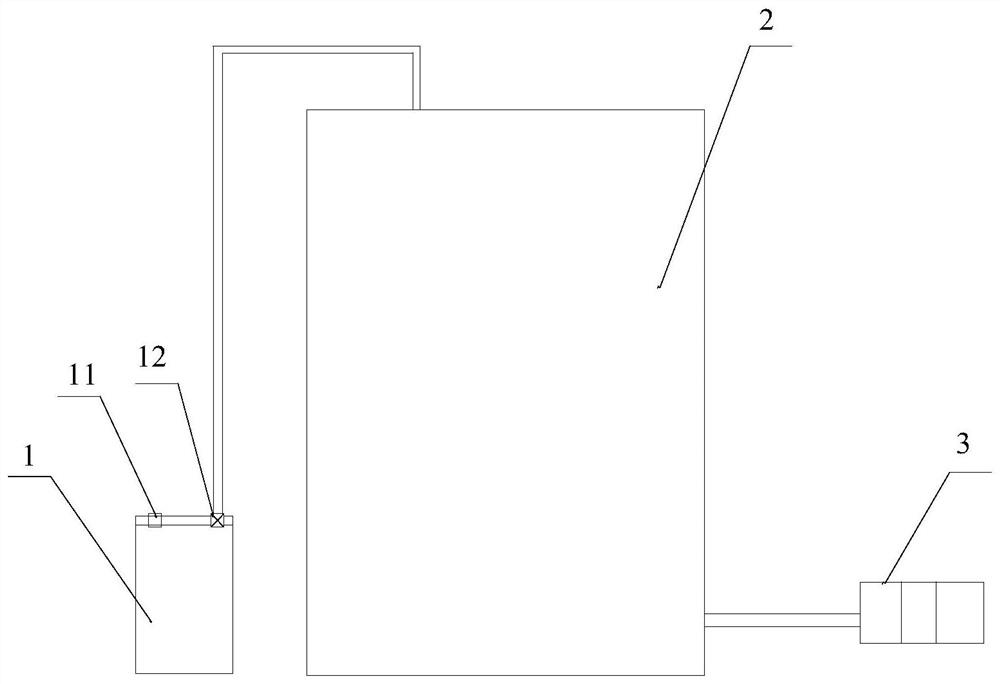

Method used

Image

Examples

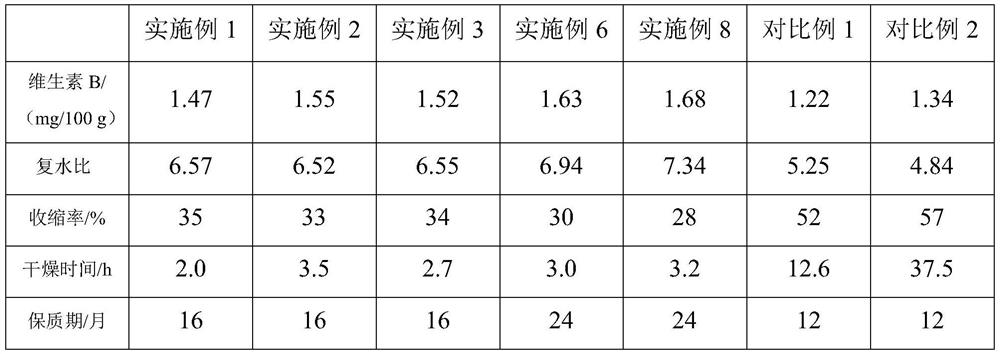

Embodiment 1

[0031] A method for preparing shiitake mushrooms with high rehydration properties by combined drying of pulsating vacuum radio frequency and microwave. The washed shiitake mushrooms are placed in a closed material processing bin, and pulsating pressure is circulated into the material processing bin, and combined with radio frequency and microwave Jointly dry the shiitake mushrooms until the water content is 15%, and then dry the shiitake mushrooms with hot air at 60°C until the water content is lower than 10%. A pulsation period of the pulsating pressure is specifically: 1) The time for releasing the normal pressure to the low pressure is less than 0.2 s; 2) keep at low pressure for 5min; 3) the time for raising the low pressure to normal pressure is 12s; 4) keep at normal pressure for 2min, and use radio frequency and microwave to dry shiitake mushrooms simultaneously in this stage (this stage refers to 4) within 2 minutes under normal pressure);

[0032] Wherein, in step 4),...

Embodiment 2

[0035] A method for preparing shiitake mushrooms with high rehydration properties by combined drying of pulsating vacuum radio frequency and microwave. The washed shiitake mushrooms are placed in a closed material processing bin, and pulsating pressure is circulated into the material processing bin, and combined with radio frequency and microwave Combined drying of shiitake mushrooms until the water content is 35%, and then drying the shiitake mushrooms in the sun until the water content is lower than 10%. A pulsation period of the pulsating pressure is specifically: 1) The time for releasing the normal pressure to the low pressure is less than 0.2s; 2) Keep under low pressure for 10 minutes; 3) The time to raise the low pressure to normal pressure is 60s; 4) Keep under normal pressure for 5 minutes, and use radio frequency and microwave to dry the shiitake mushrooms at the same time during this stage;

[0036] Wherein, in step 4), the temperature in the material processing cha...

Embodiment 3

[0039] A method for preparing shiitake mushrooms with high rehydration properties by combined drying of pulsating vacuum radio frequency and microwave. The washed shiitake mushrooms are placed in a closed material processing bin, and pulsating pressure is circulated into the material processing bin, and combined with radio frequency and microwave Jointly dry the shiitake mushrooms until the water content is 20%, then dry the shiitake mushrooms with hot air at 60°C until the water content is lower than 10%. A pulsation period of the pulsating pressure is specifically: 1) The time for releasing the normal pressure to the low pressure is less than 0.2 s; 2) Keep the low pressure for 8 minutes; 3) The time for raising the low pressure to normal pressure is 30s; 4) Keep it for 3 minutes under normal pressure, and use radio frequency and microwave to dry the shiitake mushrooms at the same time during this stage;

[0040] Wherein, in step 4), the temperature in the material processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com