Adaptive multi-frequency ultrasonic-vibration low-resistance wear-resistance subsoiler and operation method thereof

An ultrasonic vibration, multi-frequency ultrasonic technology, applied in applications, agricultural machinery and implements, force/torque/work measuring instruments, etc., can solve the problem of lack of key research on the wear of key components of the subsoil shovel, and the effect of reducing viscosity and reducing drag is general. Increase the energy consumption of tractors and other issues, to achieve the effect of increasing the ability to absorb water and nutrients, reducing the dependence on imported parts, and improving output and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

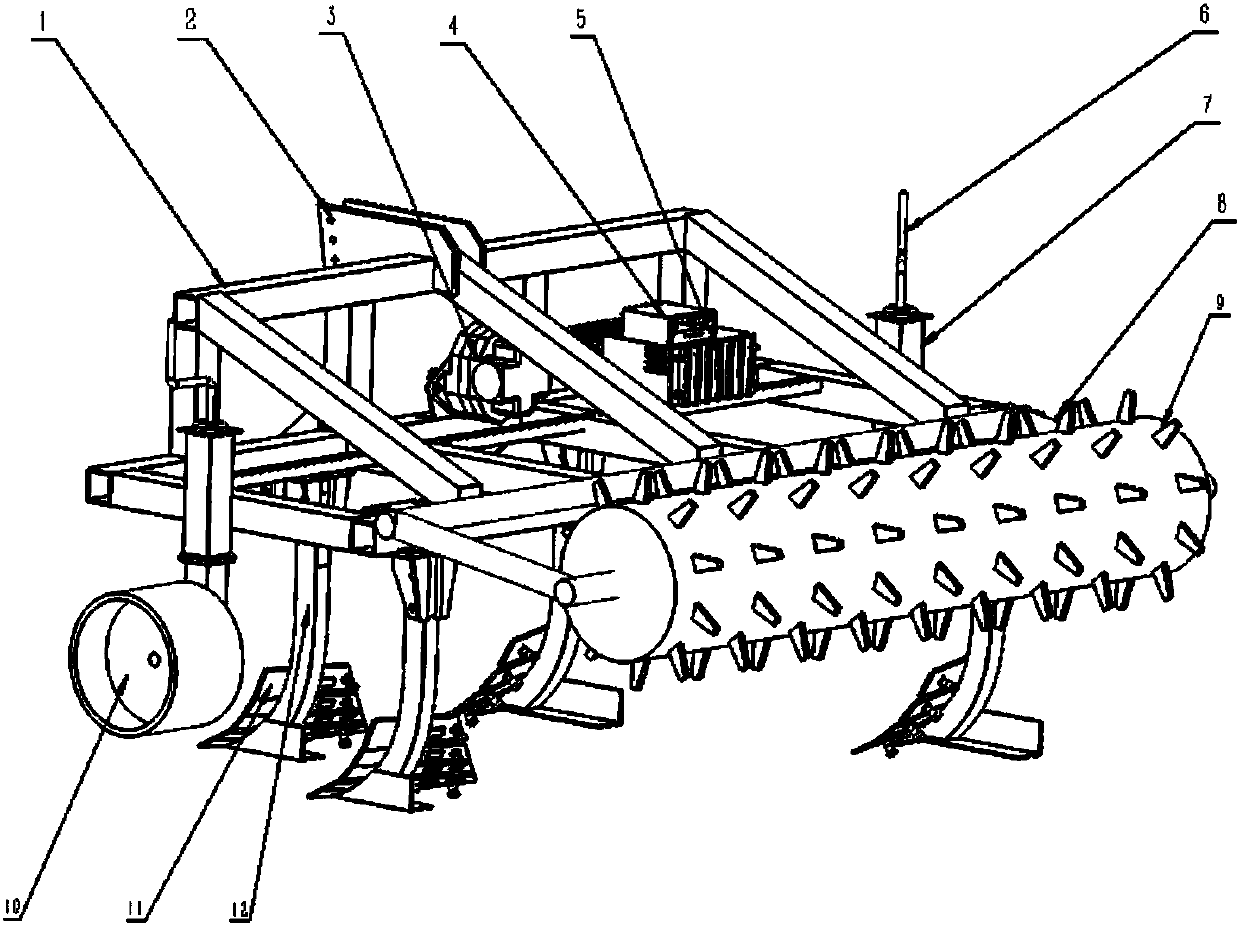

[0032] Below in conjunction with accompanying drawing, the patent of the present invention is further described. The invention provides an adaptive multi-frequency ultrasonic vibration low-resistance wear-resistant subsoiler, such as figure 1 As shown, the frame (1) is composed of mutually connected and fixed square pipes and suspension devices (2), and is used to install and fix other devices, and is articulated with the suspension system of the tractor to pull the implements, Subsoiling work tools and ultrasonic generators provide power.

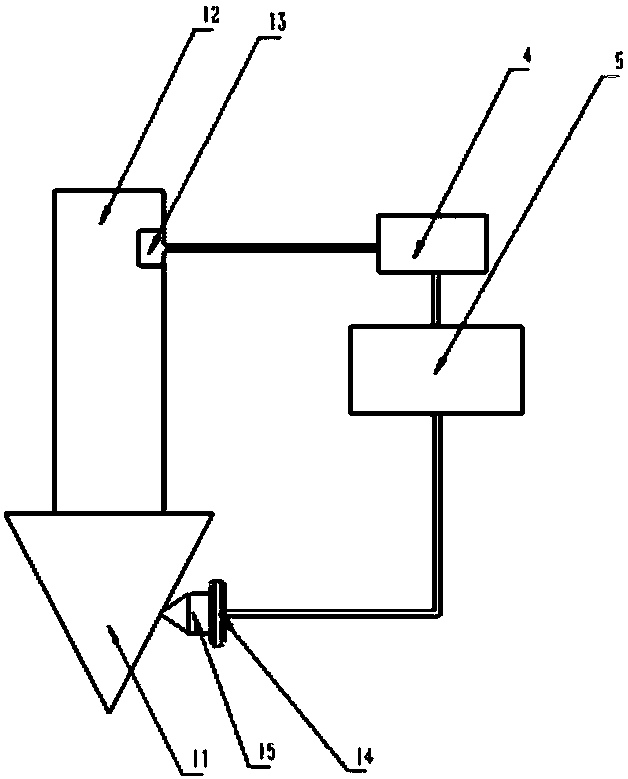

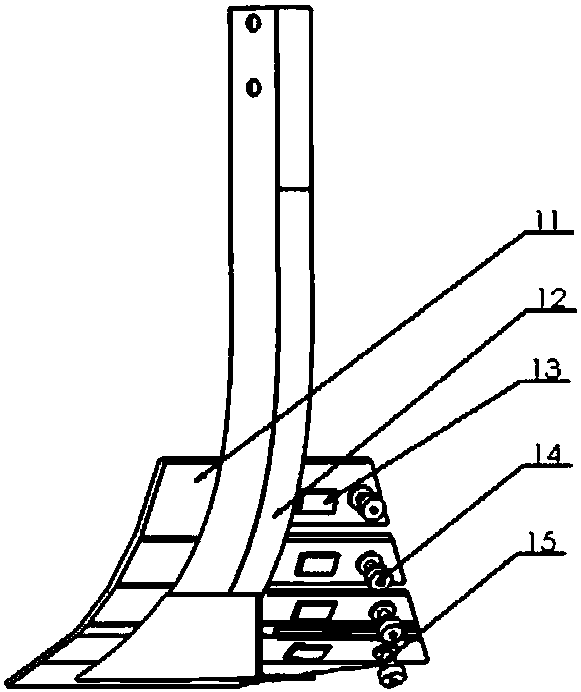

[0033] The aforementioned subsoiling plowing and land preparation device is composed of a subsoiling shovel group, a depth control device and a suppression device. The subsoiling shovel group is composed of a subsoiling shovel handle (12) and an ultrasonic vibration shovel surface (11), the subsoiling shovel handle (12) is connected with the frame (1) through a U-shaped bolt, and the ultrasonic vibration shovel surface ( 11) Use bolts to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com