Harmonic current suppression method for refrigerator, frequency conversion plate and refrigerator refrigeration system

A technology of harmonic current and frequency conversion board, which is applied in the field of refrigeration control, can solve problems such as failure to meet EMI standard requirements, mismatch of multiple components, and reduced energy efficiency of the whole machine, so as to suppress harmonic current, reduce production difficulty, and reduce standby time The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

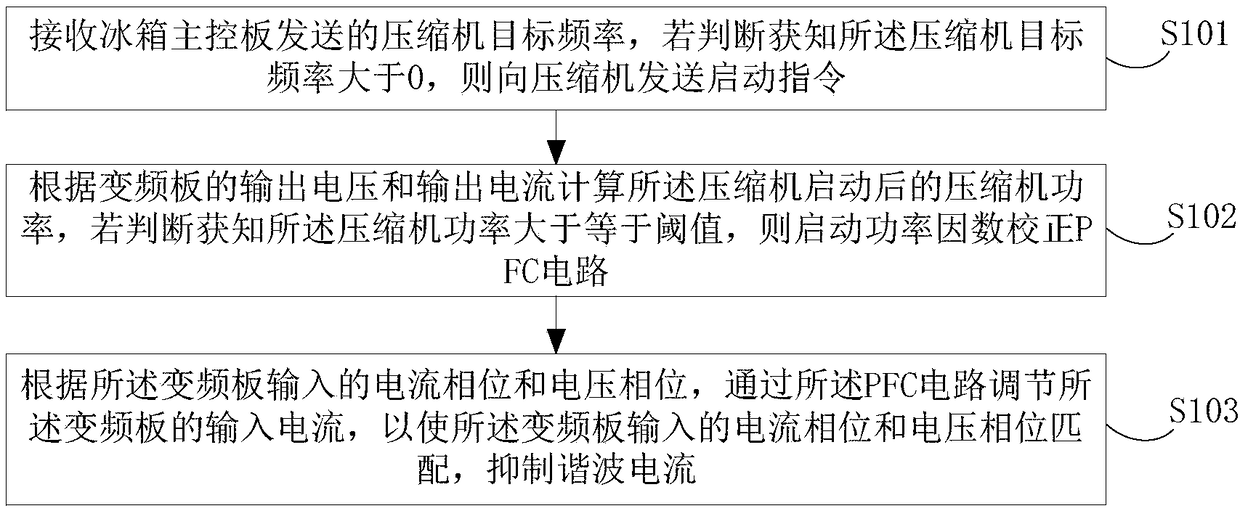

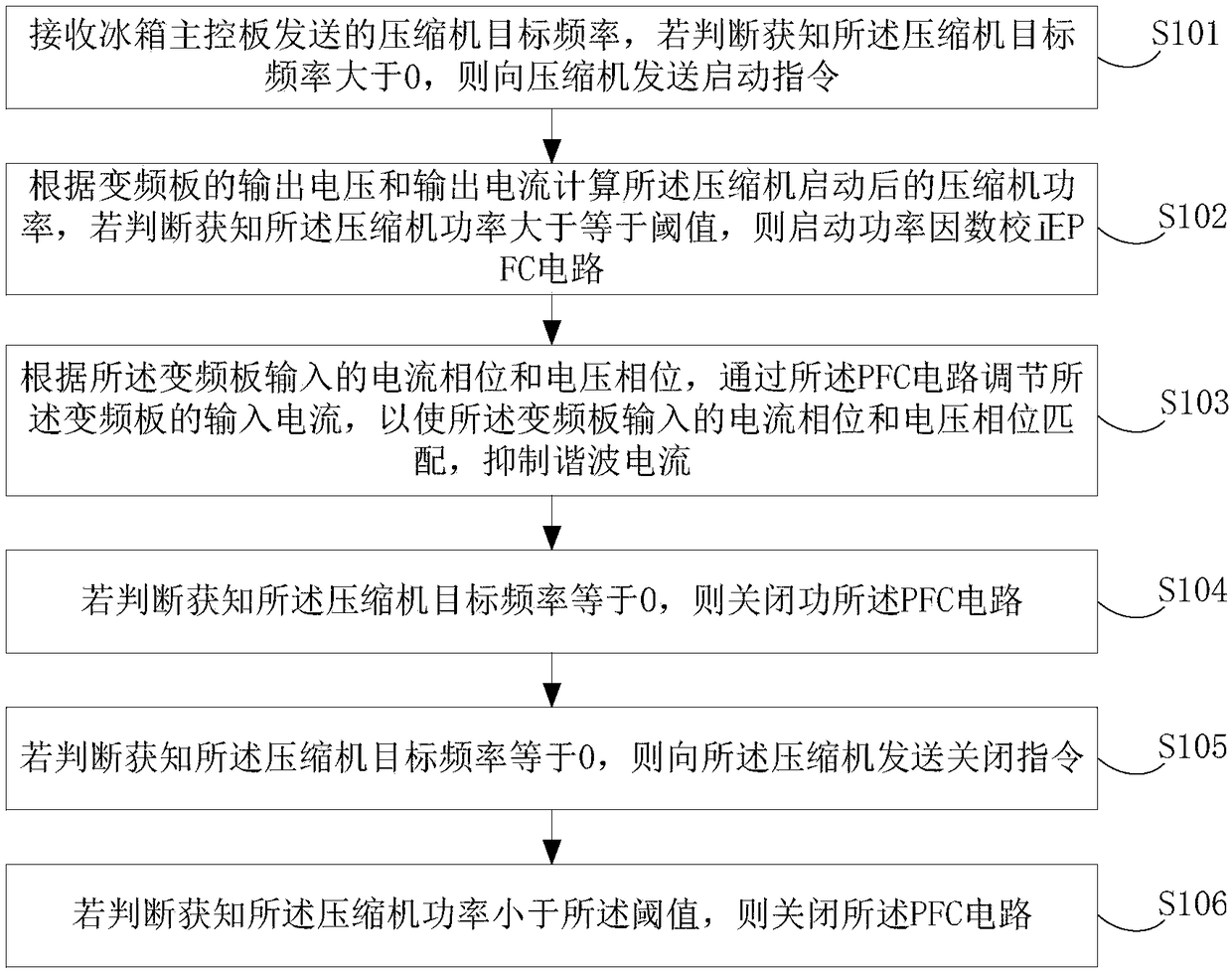

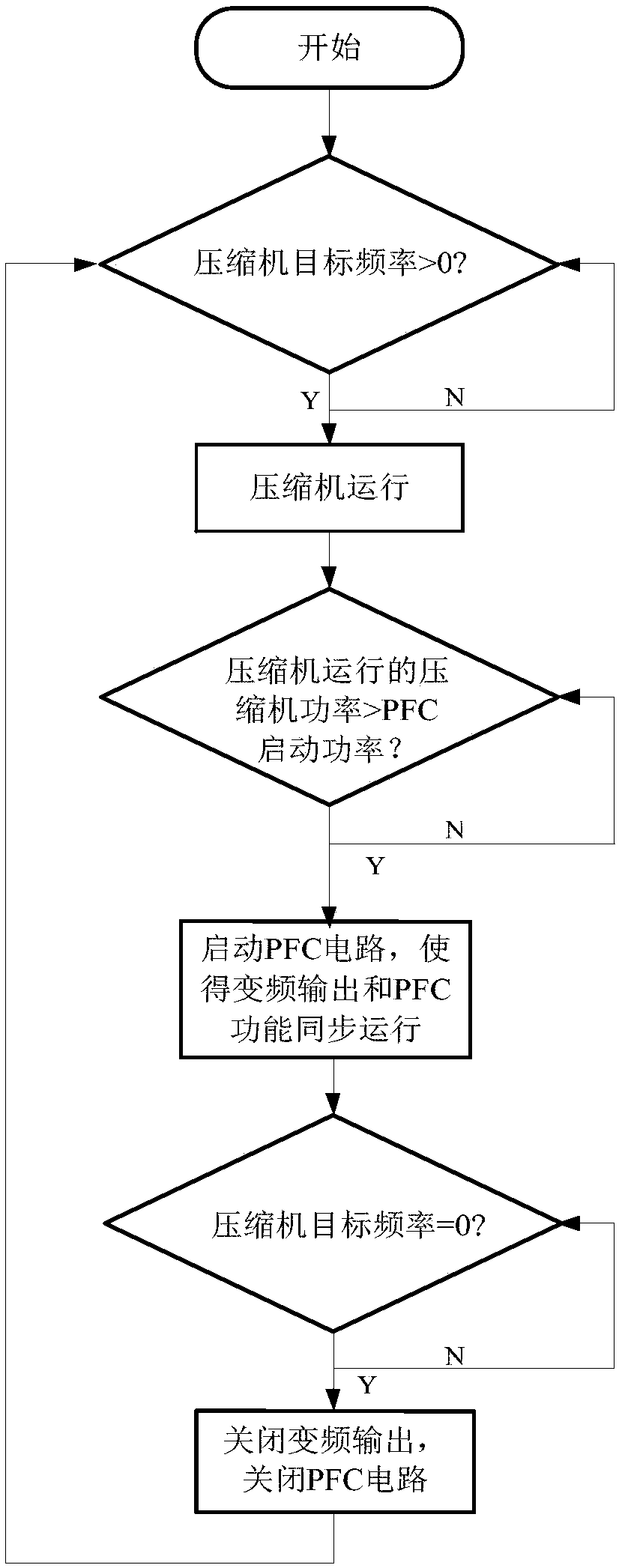

[0041] figure 1 A schematic flowchart of a method for suppressing harmonic current of a refrigerator provided in this embodiment is shown, including:

[0042] S101. Receive the target frequency of the compressor sent by the main control board of the refrigerator, and if it is determined that the target frequency of the compressor is greater than 0, send a starting command to the compressor.

[0043] Specifically, the main control board of the refrigerator calculates the theoretical frequency of the compressor in the refrigerator according to environmental factors such as the current temperature and humidity of the refrigerator, that is, the target frequency of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com