Diesel engine plateau cold-start preheating method

A diesel engine and cold start technology, which is applied in the direction of engine start, machine/engine, mechanical equipment, etc., can solve the problems of poor environmental adaptability, real-time performance constraints, and large computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0018] A method for preheating a diesel engine at a plateau cold start, comprising the steps of:

[0019] After the diesel engine electronic control system is powered on, the sensor collects the coolant temperature and the intake air temperature, and judges whether the minimum value of the coolant temperature and the intake air temperature is lower than -5°C. If it is, the intake air needs to be preheated. warm up;

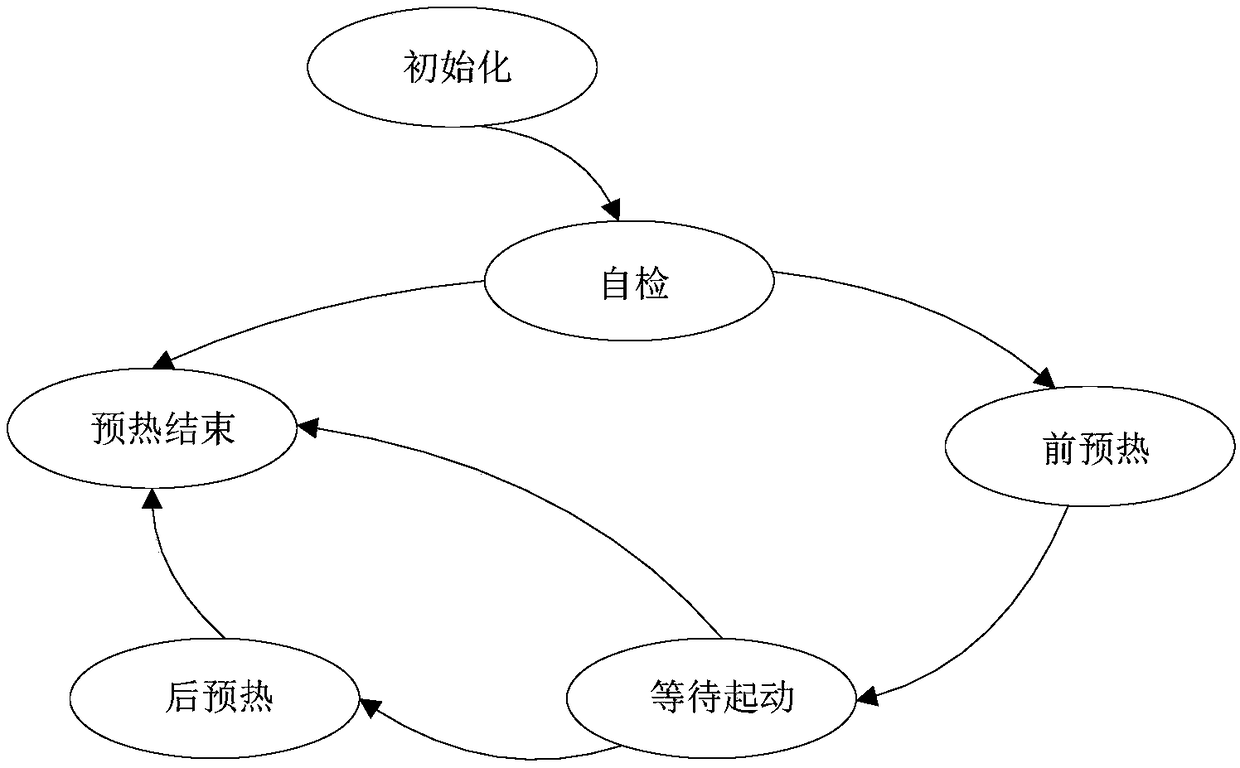

[0020] Perform variable initialization and fault self-inspection for the flame preheater installed at the intake manifold;

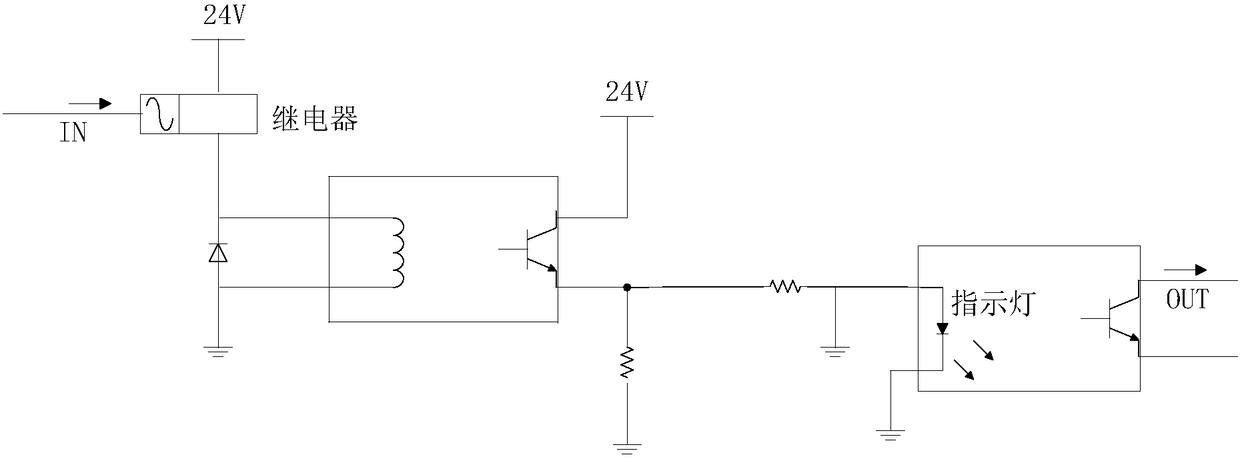

[0021] When there is no fault in the self-inspection, enter the preheating process, control the preheating plug to perform intake heating according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com