Bearing chamber for vertical pump

A bearing chamber, vertical pump technology, applied to the components of the pumping device for elastic fluid, non-variable-capacity pumps, pumps, etc., can solve the problem of reducing lubrication and heat dissipation effects, affecting the normal operation of the pump, and oil storage space Restriction and other issues to achieve the effect of improving lubrication and heat dissipation, facilitating heat dissipation and lubrication, and increasing oil storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

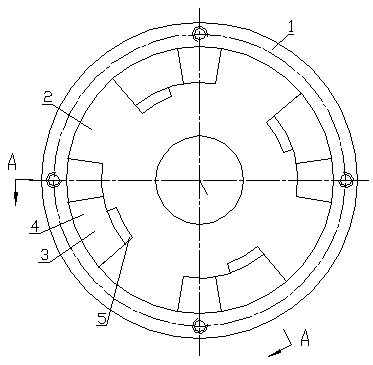

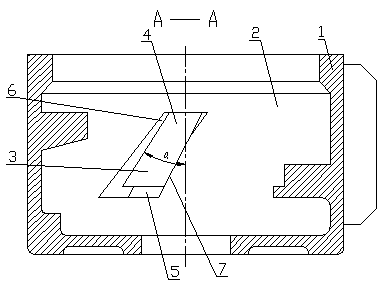

[0013] Such as figure 1 , figure 2 As shown, the bearing chamber 1 for a vertical pump includes a vertical bearing chamber cavity 2 with a stepped hole, and four inwardly protruding bearings are fixedly connected to the inner wall of the bearing chamber cavity 2 at intervals. Ring support ribs 3, four bearing outer ring support ribs 3 are evenly distributed on the circumference, each bearing outer ring support ribs 3 includes a radial support block 4 with an inner arc surface, integrally connected to the radial direction The longitudinal support step 5 at the lower end of the support block 4, the inner end of the longitudinal support step 5 is located on the inner side of the inner arc surface, and the two sides 6, 7 of the radial support block 4 are slopes with a certain angle with the vertical direction, and the two The inclined directions of the sides 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com