Large pump strong backflow large pump single injection compound pump valve

A compound pump and large pump technology, applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of blockage, loss of a large number of injection channels and a small amount of injection channels, backflow prevention and reduction, and reduce manufacturing costs. The effect of reducing wear and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

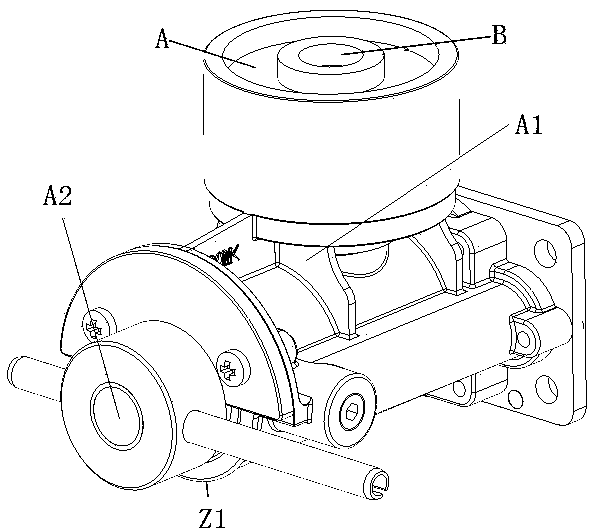

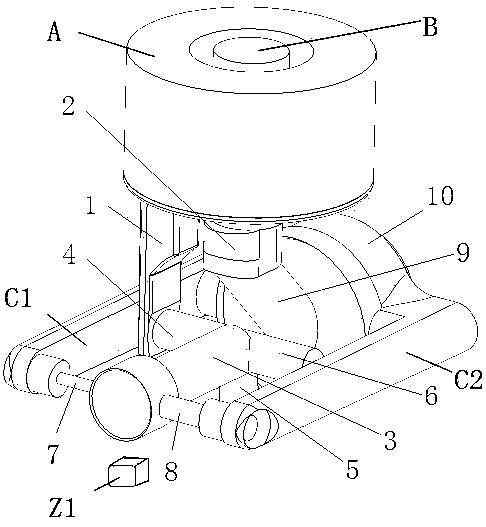

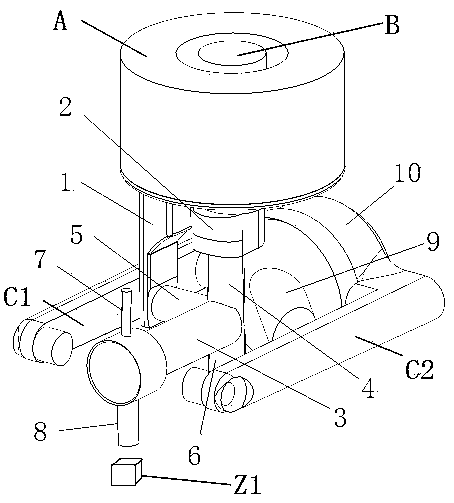

[0054] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0055] Such as Figure 1-Figure 41 As shown, the single-injection compound pump valve of the large pump with strong backflow and large pump includes the large and small pumps with piston structure. The end face of the large piston in the pump cavity protrudes from the small piston, the small piston and the small pump cavity form a small pump, and the large pump and small pump form a compound pump; and the control valve for controlling the circulation of the large and small compound pumps, the control valve includes a valve body and a valve core , the valve body is provided with a spool cavity for the rotating spool, and the spool is placed in the spool cavity; there is channel A on the valve body, one end of channel A is connected with the large pump, and channel B is set on the valve body, and one end of channel B is connected to the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com