Stair steel framework for building

A technology for steel formwork and construction, applied in construction, building structure, formwork/formwork components, etc., can solve the problems of difficult to grasp thickness tolerance, long time for workers to set up the formwork, poor quality of concrete components and unsightly appearance, etc. The disassembly and height adjustment are flexible and convenient, the formwork reuse rate is high, and the effect of shortening the time for workers to set the formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

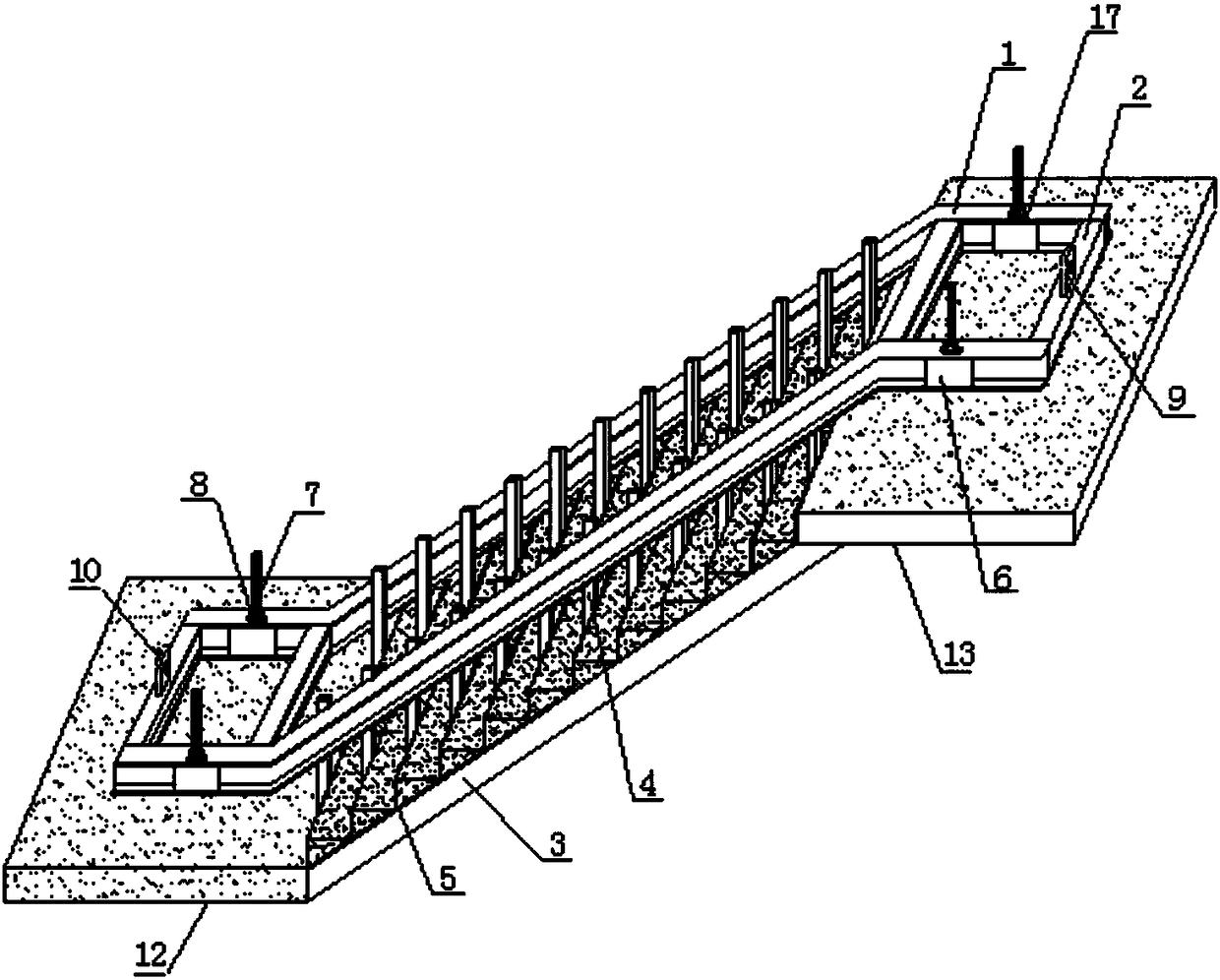

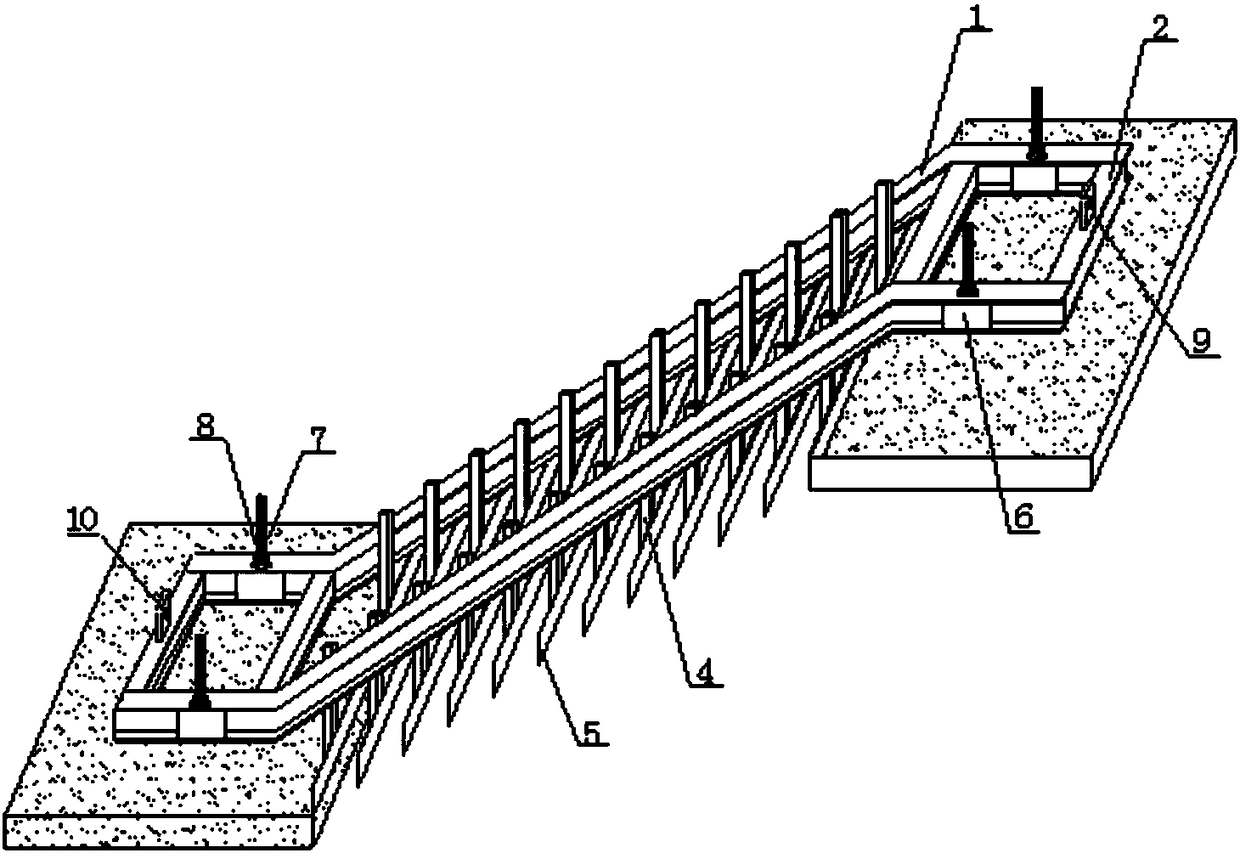

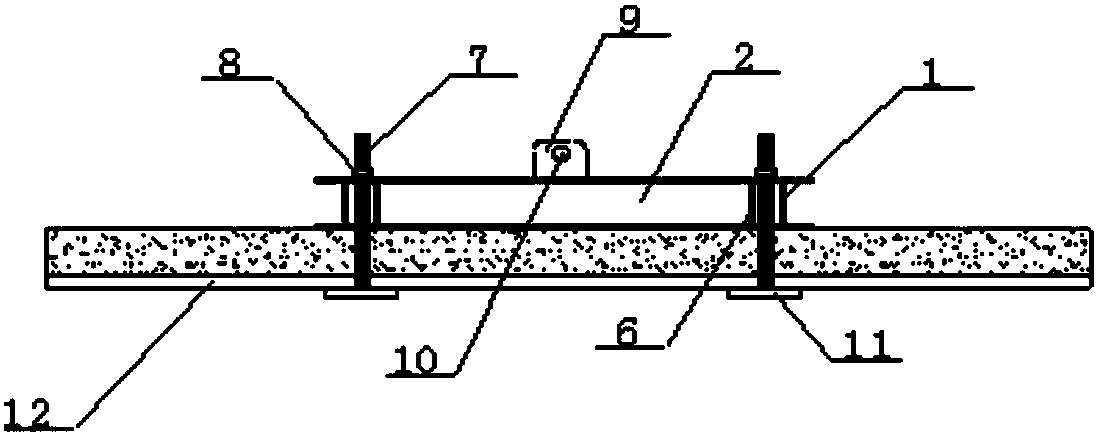

[0024] Attached below Figure 1-8 The present invention is described in detail below.

[0025] like Figure 1-8 As shown, the present invention comprises two main stair beams 1, a stair beam 2 and a stair floor 3, a stair beam 2 is arranged in the middle of the two stair main beams 1, and the stair beam 2 is welded on the stair main beam 1, so The stair main beam 1 is provided with a stepping vertical rib 4, and the stepping vertical rib 4 is welded on the stair main beam 1, and the stair main beam 1 is provided with a reinforcing plate 6, and the stair main beam 6 is welded on the stair main beam 1, the back of the stair base 3 is provided with vertical ribs 16 and transverse ribs 15, the vertical ribs 16 and transverse ribs 15 are welded on the back of the stair base 3, and the stair base 3 is provided with a front base 12 and a rear base 13. The front base plate 12 and the rear base plate 13 are respectively welded to the two ends of the stair base plate 3, and the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com