Dyeing proofer

A technology of proofing machine and dyeing cup, applied in the field of dyeing proofing machine, can solve the problems of low proofing efficiency and single temperature control, and achieve the effects of improving efficiency, accurate proofing temperature and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

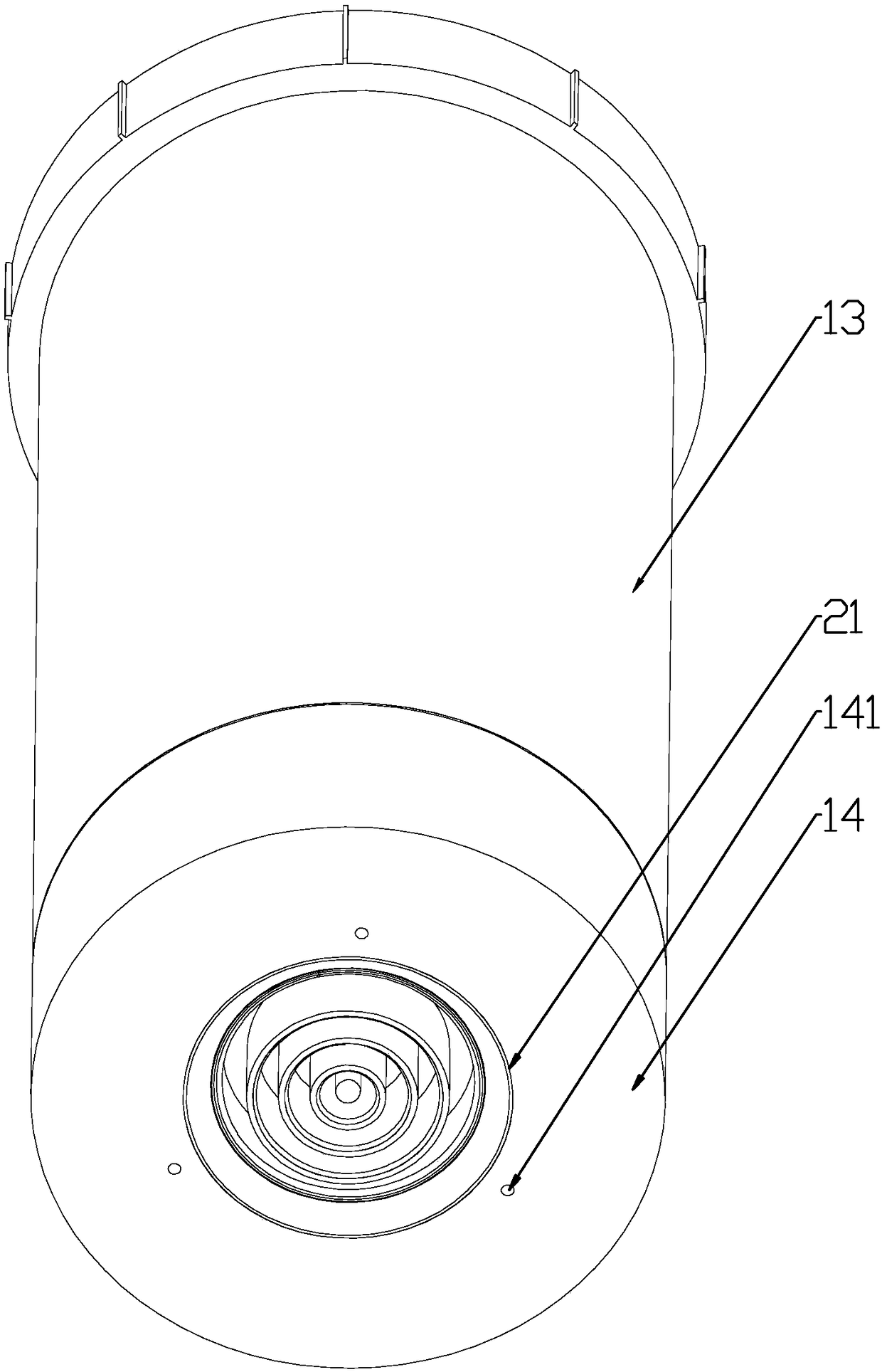

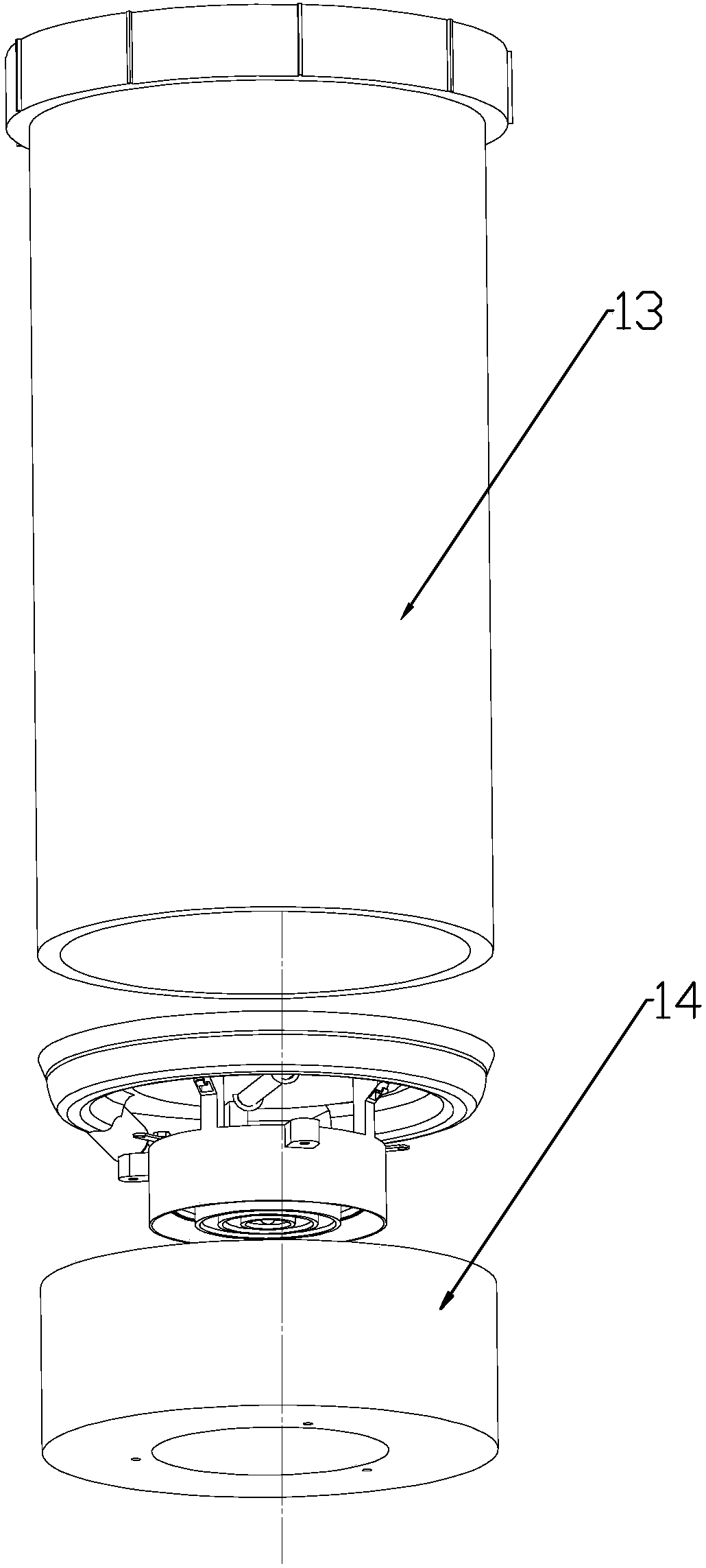

[0033] The dyeing and proofing machine of this embodiment combines figure 1 , including a dyeing cup 1, a circuit coupler 2 and a controller (not marked in the figure) arranged on the console 3, the dyeing cup 1 is provided with a temperature measuring element 11 and a heating element 12, and the heating element 12 and the temperature measuring element 11 pass through The circuit coupler 2 is connected with the controller, combining Figure 10 , 11 , the heating element 12 and the temperature measuring element 11 form an electrical circuit through the circuit coupler 2 . The temperature is set by the controller, and the setting is transmitted to the temperature measuring element 1 through the circuit coupler 2. The temperature measuring element 11 compares the obtained set value with the temperature of the dye liquor and forms a signal. signal, to heat-treat the dye solution to be treated in the dyeing cup 1.

[0034] In order to achieve more effects, the above scheme can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com