A Crank Angle Virtual Method for Toggle-Joint Servo Press

A servo press, crank angle technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve problems that are difficult to obtain analysis, reverse solve calculation complexity, etc., and achieve the effect of simplifying the difficulty of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

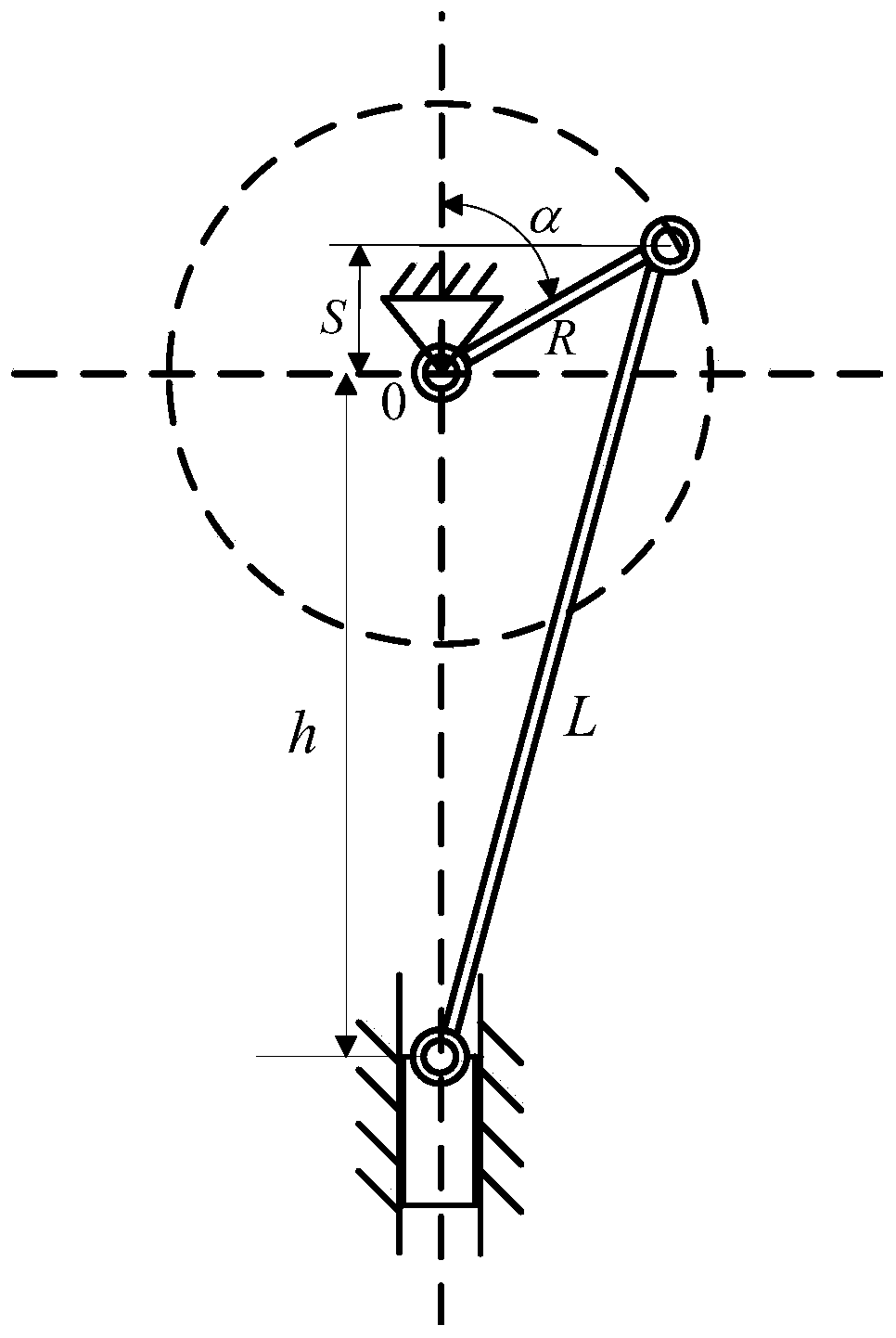

[0041] Such as figure 1 As shown in the schematic diagram of the transmission structure of the existing crank-link servo press, the crank angle at the bottom dead center of the crank-link servo press with the nodes upright is 180°. The transmission mechanisms of the crank-link servo presses mentioned in this application all refer to the nodes being upright.

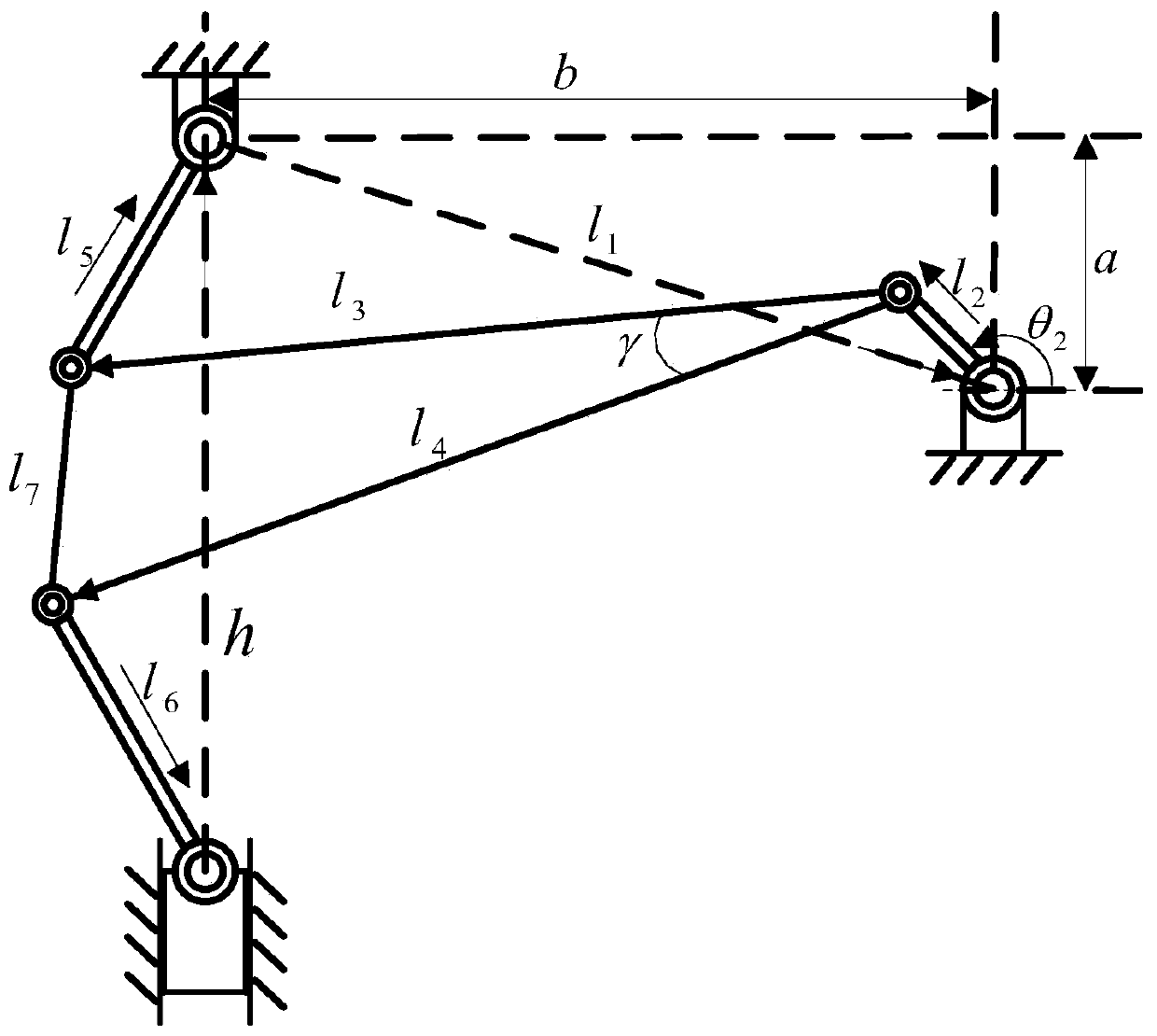

[0042] Such as figure 2 As shown, in the transmission mechanism of the toggle servo press of the present application, due to its special mechanical characteristics, the crank angle at the bottom dead center of the toggle servo press is not 180°.

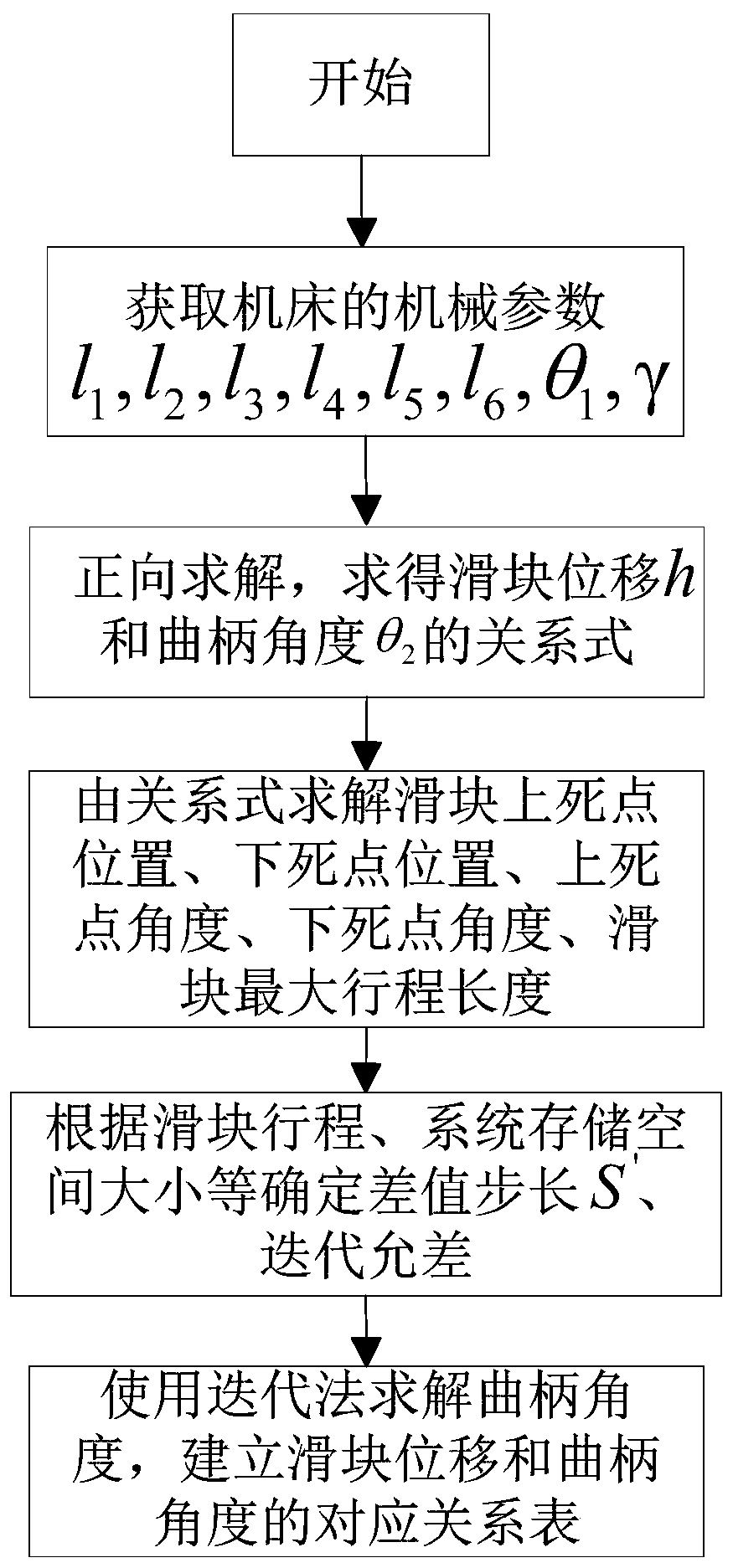

[0043] A crank angle virtual method of a toggle-type servo press disclosed in the present application comprises the following steps:

[0044] Step 1, establish the mathematical model of the crank-slider mechanism of the crank-link servo press, and obtain according to the geometric relationship of the triangle:

[0045] (s-h) 2 = L 2 -(Rsinα) 2

[0046] In the formula, h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com