Large-travel mold clamping device

A clamp and large-stroke technology, applied in the field of large-stroke clamps, can solve problems such as large gaps, high requirements for mold edge thickness, and small clamp strokes, and achieve low manufacturing difficulty, lower thickness requirements, The effect of large clamping stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

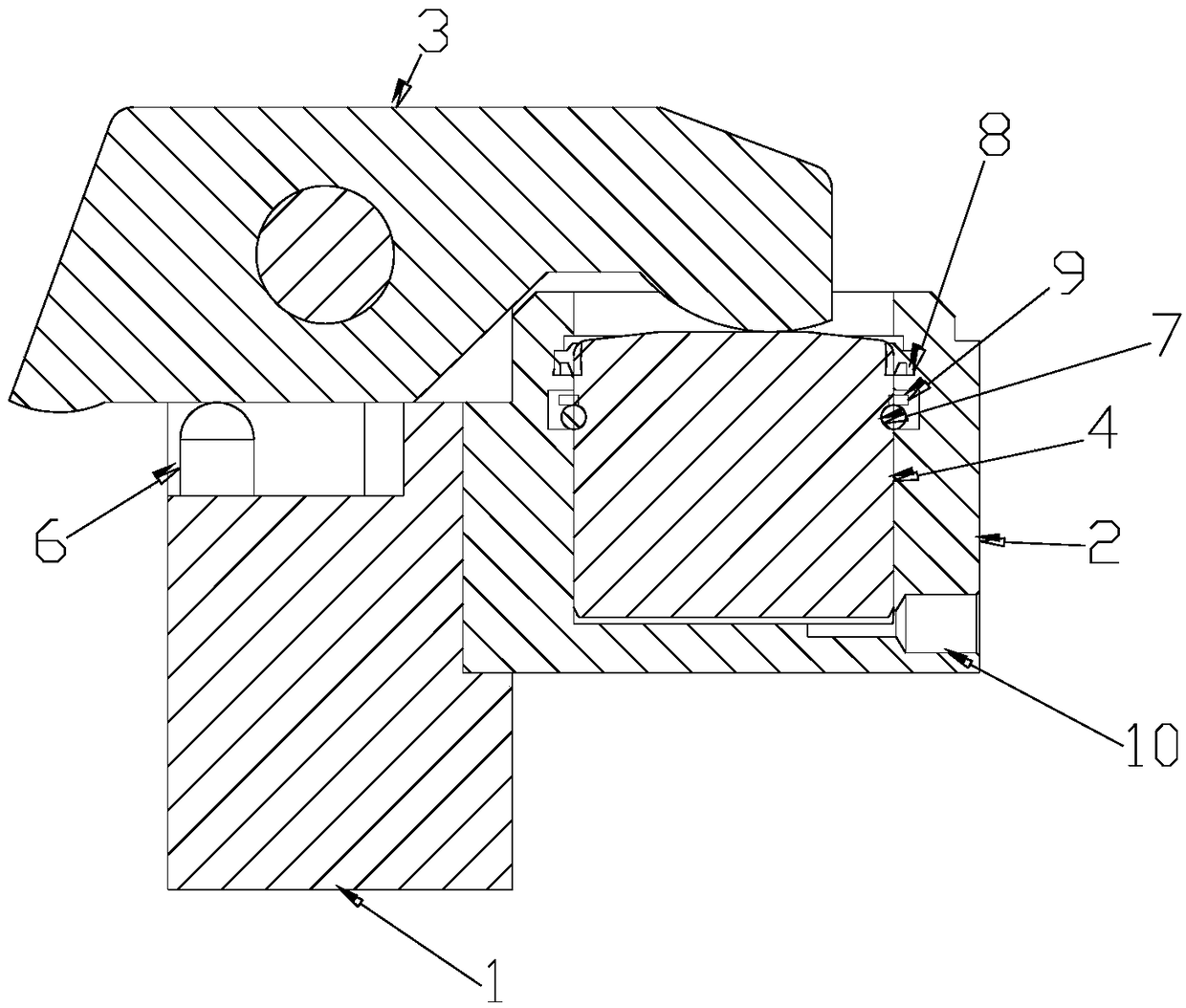

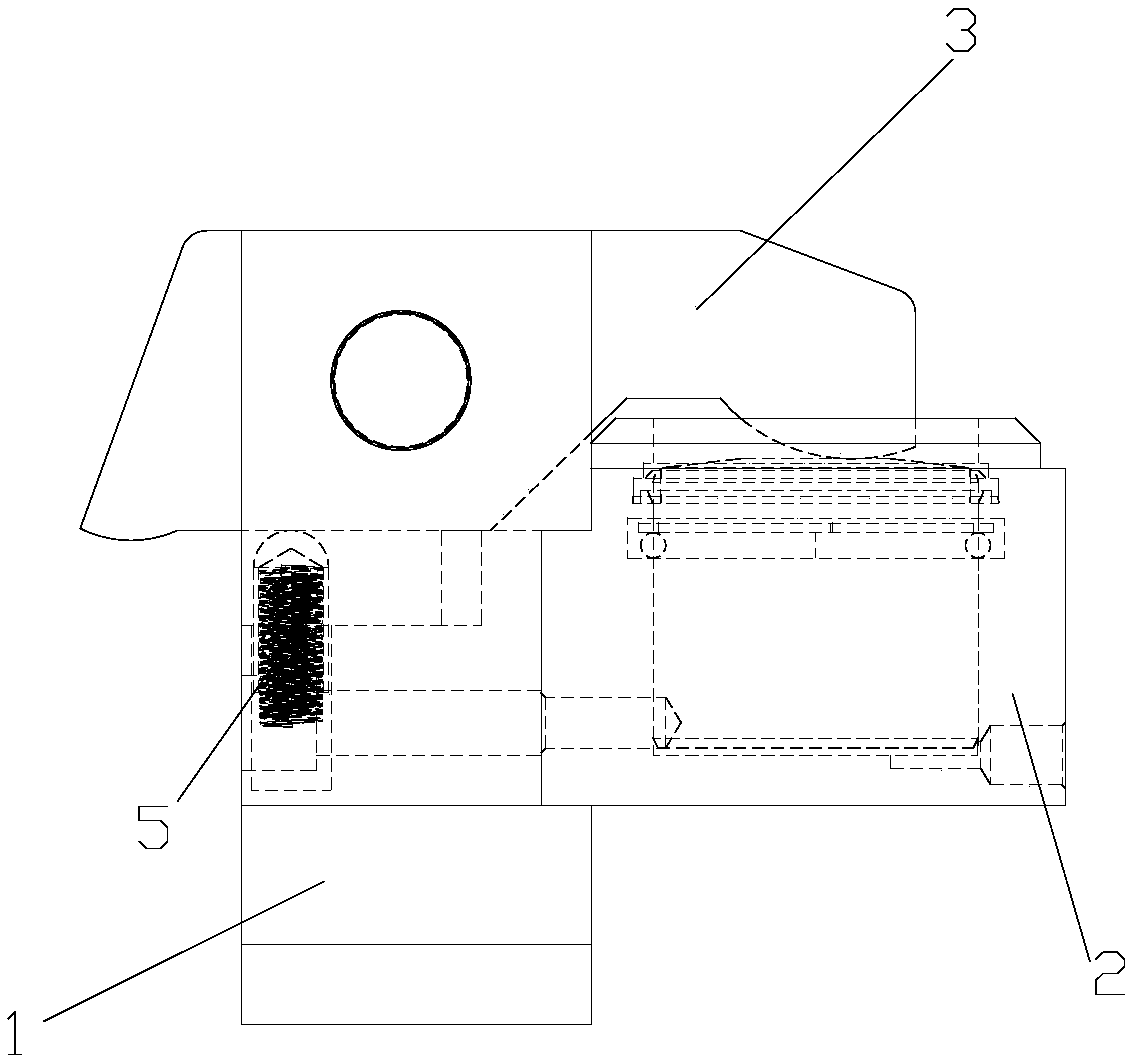

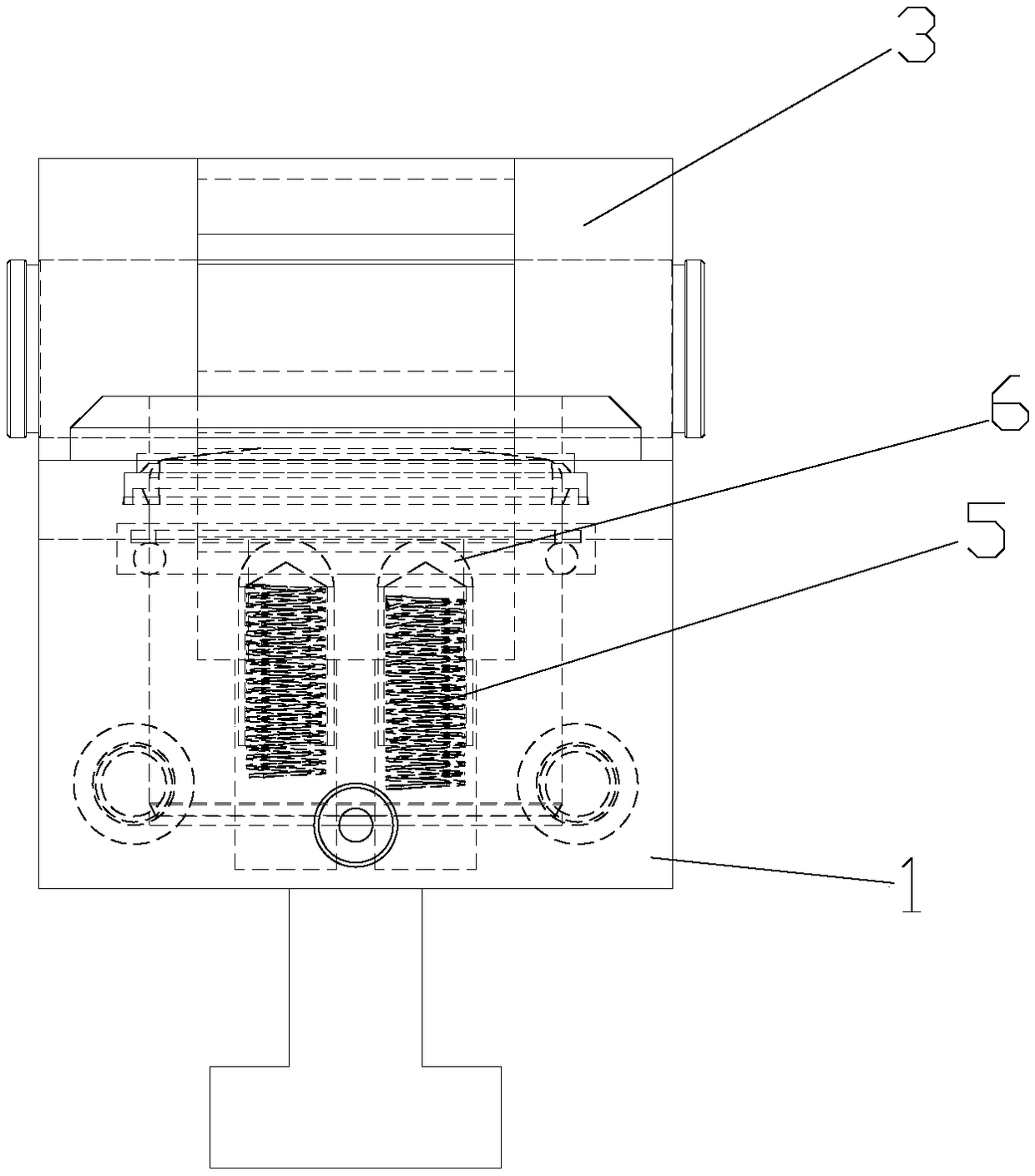

[0013] Such as Figure 1 to Figure 3 A large-stroke mold clamp shown includes a first body 1, and a second body 2 is fixedly connected to one side of the first body 1. The fixing method can be welding, screw connection, etc., and the first body 1 is hinged with a pressure plate 3, one side of the pressure plate 3 protrudes from the first body 1, the other side of the pressure plate 3 is located above the second body 2, a cavity is provided in the second body 2, and the One side of the bottom of the second body 2 is provided with an oil inlet and outlet port 10 communicating with the cavity. A piston 4 that can extend out of the body is also provided in the cavity. Contact, the first body 1 is also provided with a spring mechanism, one end of the spring mechanism is fixed in the first body 1, and the other end of the spring mechanism is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com