Woven bag hot opening device

A technology of opening device and woven bag, applied in the field of cutting device, can solve the problems of inability to separate the opening of the woven bag in time, adhesion of the woven bag, etc., and achieve the effects of good cooling effect, avoidance of adhesion and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

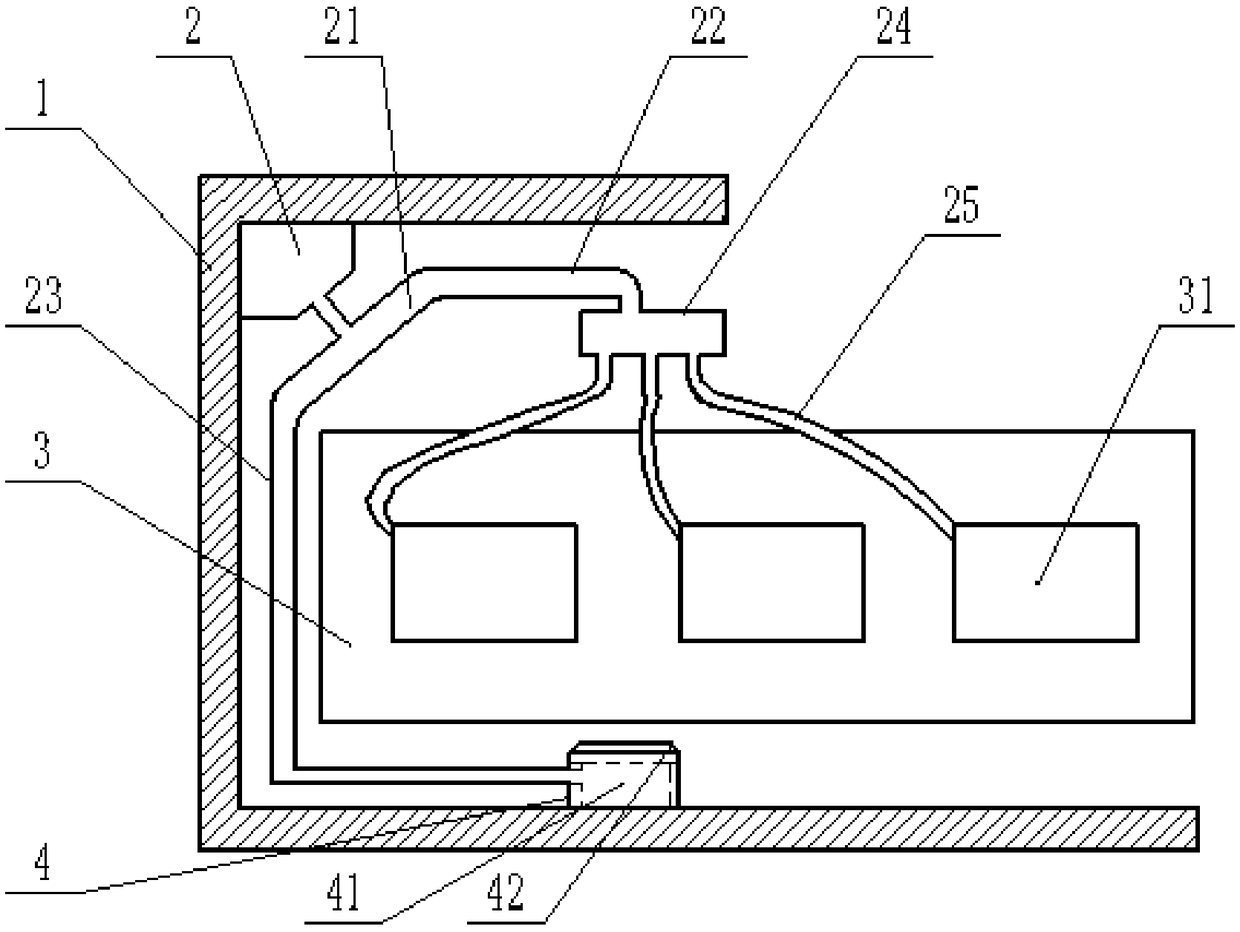

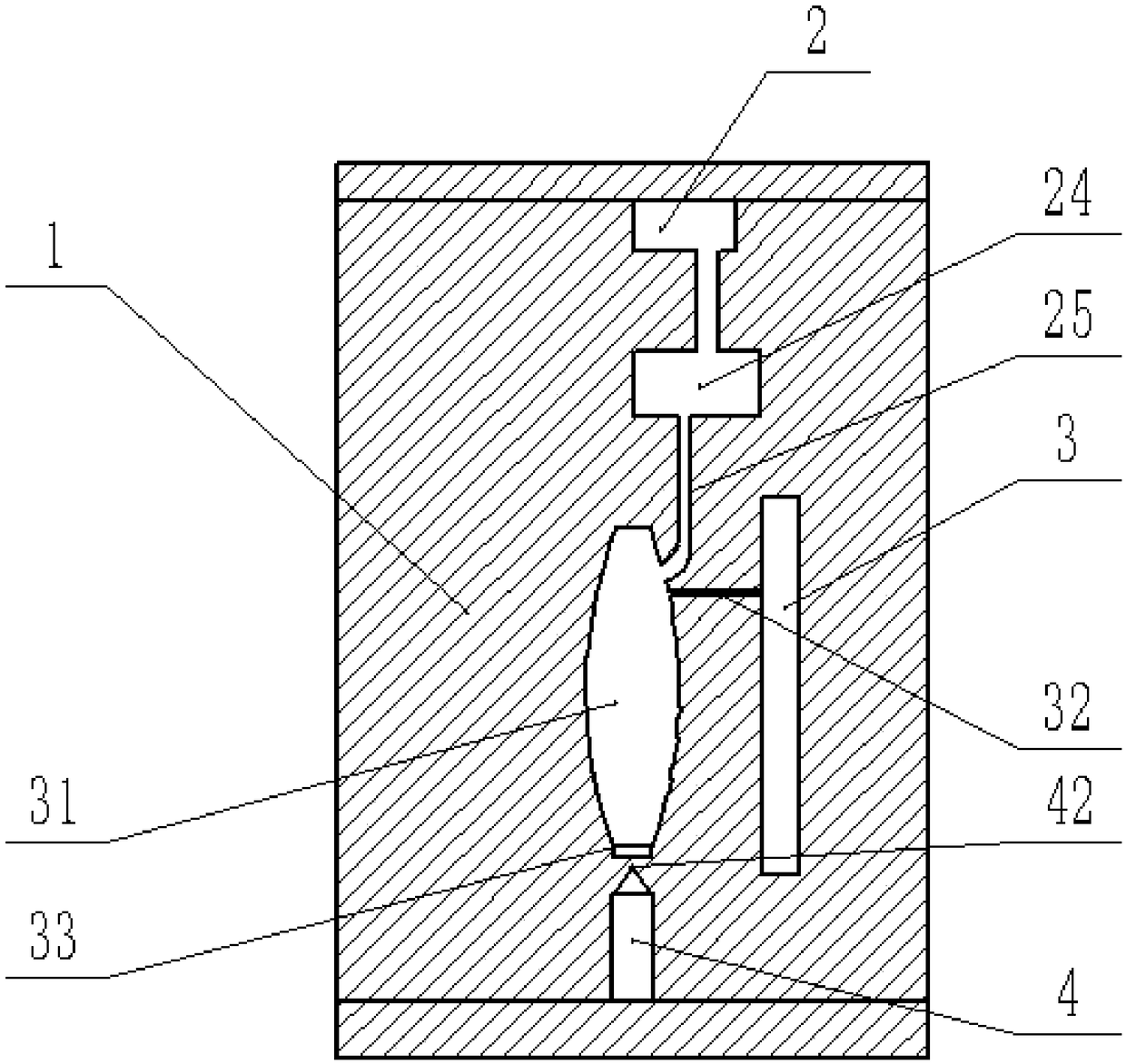

[0021] The reference signs in the accompanying drawings of the description include: frame 1, compressed air supply chamber 2, vortex tube 21, cold air outlet pipe 22, hot air outlet pipe 23, diversion chamber 24, diversion branch pipe 25, conveyor belt 3, airbag roller 31, branch Rod 32, metal plate 33, base 4, hollow cavity 41, copper cutter 42.

[0022] Such as figure 1 and figure 2 As shown, the thermal opening device for woven bags includes a frame 1 on which an inflating device, a conveying device and a cutting device are fixedly connected sequentially from top to bottom.

[0023] The conveying device comprises a conveyor belt 3, three poles 32 are fixed at intervals on the conveyor belt 3, and the poles 32 and the conveyor belt 3 are vertically arranged, and each pole 32 is connected with an airbag roller 31 (in this embodiment, the pole 32 and the airbag roller 31 Quantity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com