A dual-motor driven modular joint and a robotic arm

A drive module, dual-motor technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex mechanical structure, increasing control algorithm complexity, low joint integration, etc., achieving simple algorithm and small transmission backlash , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

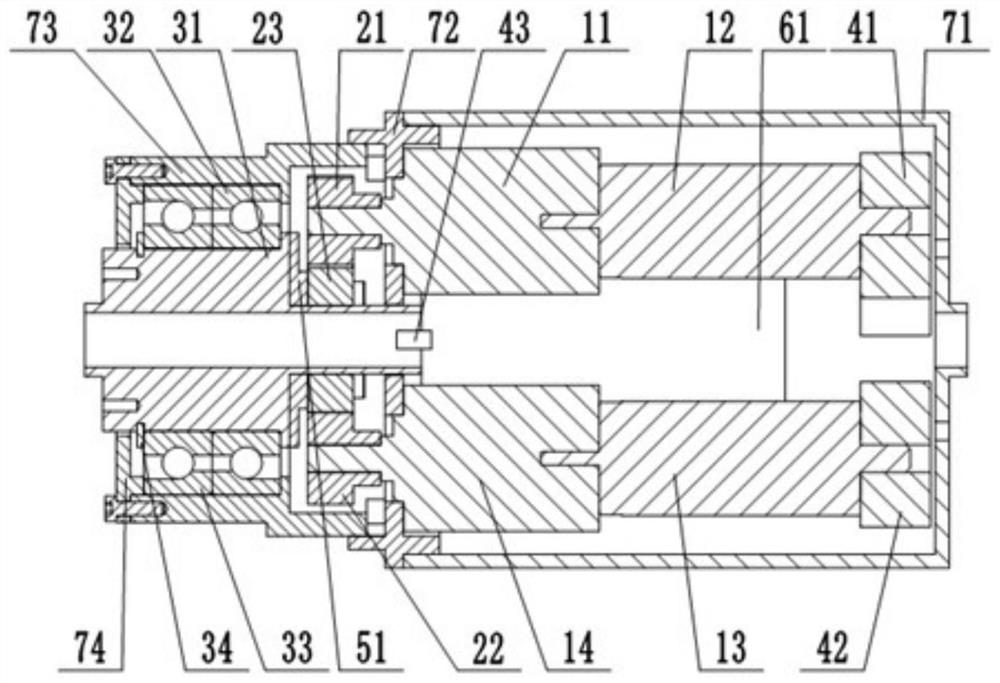

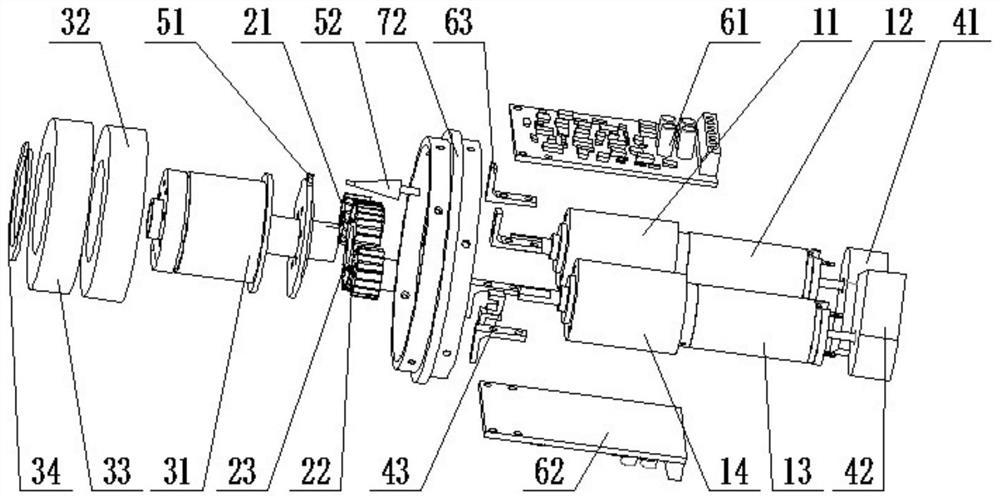

[0043] like figure 1 As shown, each component is compactly arranged in the casing.

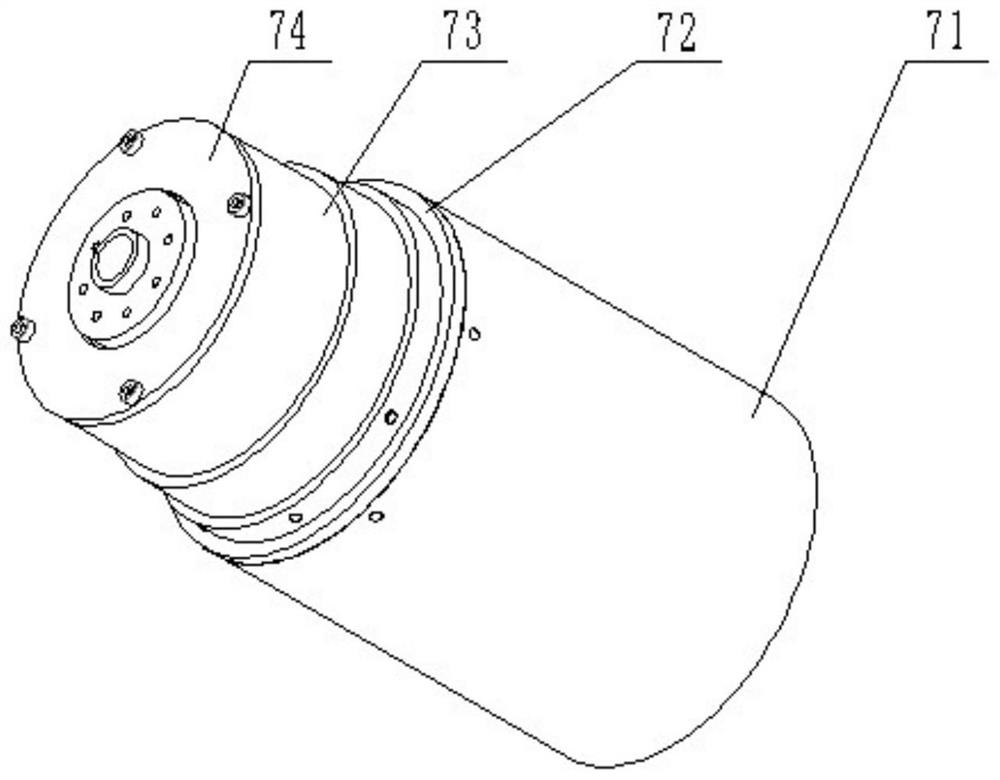

[0044] The housing includes a first joint housing 71 , a second joint housing 72 , a third joint housing 73 and an end cover 74 . The first joint housing 71 and the second joint housing 72 cooperate to form a rear chamber, and the second joint housing 72 , the third joint housing 73 and the end cover 74 cooperate to form a front chamber. The output shaft 31 is rotatably connected with the third joint housing 73 via the first bearing 32 and the second bearing 33 . The second joint casing 72 includes a hole tightly fitted with the output shaft 31 , one section of the output shaft 31 is located in the rear cavity, and one section is located in the front cavity.

[0045] The end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com