Shifting unit for gantry type CNC machining center

A processing center and mobile device technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of no moving function, no shock absorption and buffering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

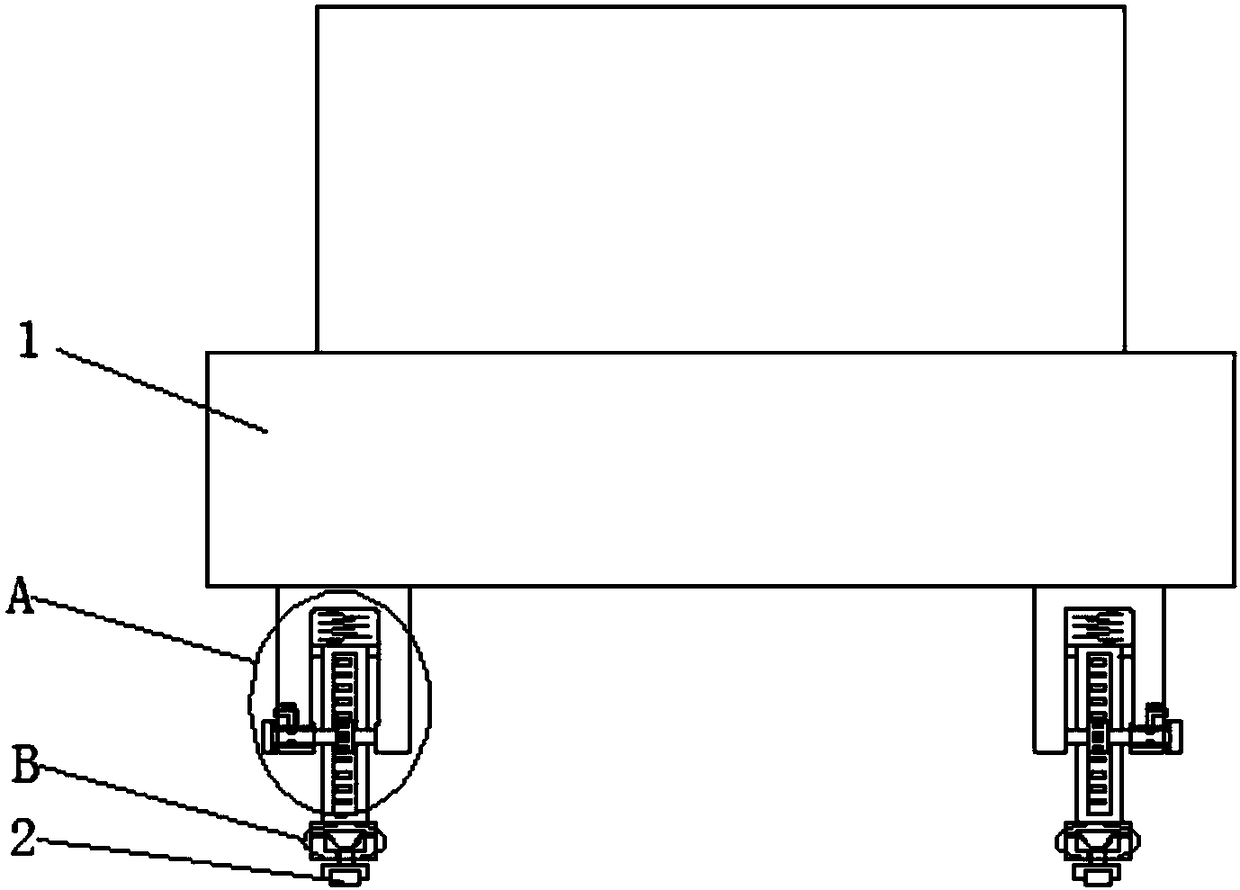

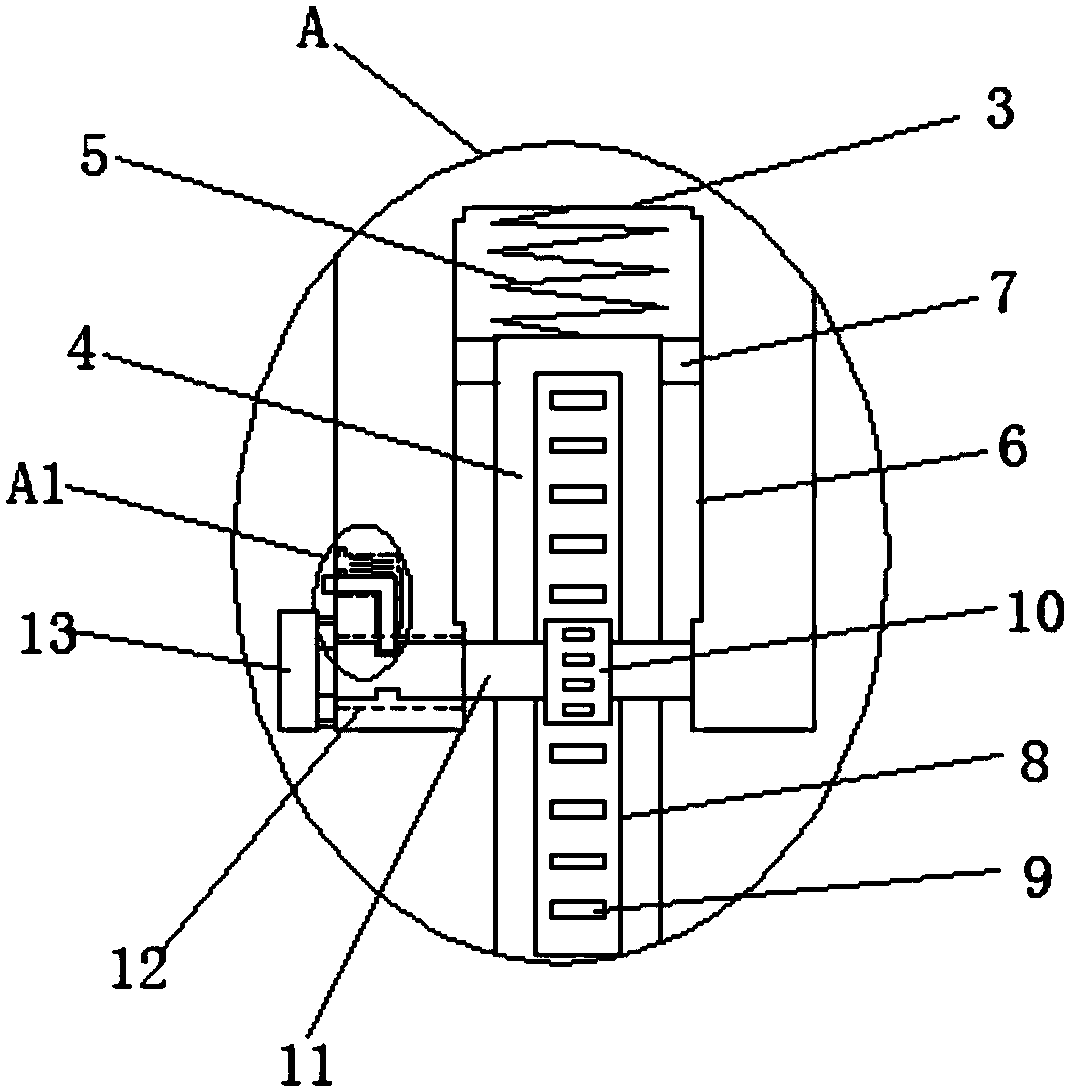

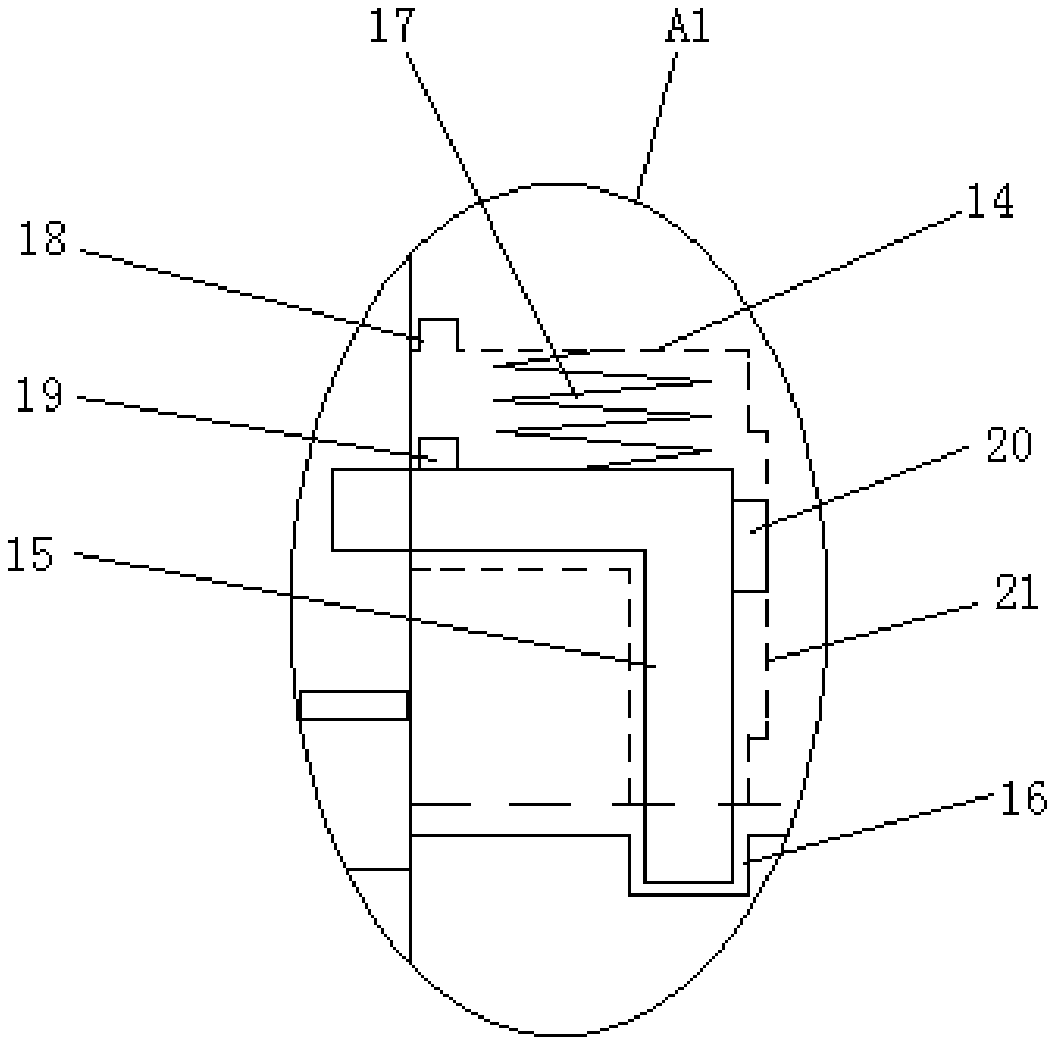

[0025] refer to Figure 1-6, a mobile device for a gantry type CNC machining center, comprising a base 1 and a CNC machining device fixedly installed on the top side of the base 1, fixed rods are fixedly installed at the four corners of the bottom side of the base 1, and a sliding door is provided at the bottom end of the fixed rod Groove 3, a sliding rod 4 is slidably installed in the sliding groove 3, the bottom end of the sliding rod 4 extends to the outside of the sliding groove 3, and a universal wheel 2 is installed, and a placement groove 8 is provided on one side of the sliding rod 4, A rack 9 is fixedly installed in the placement groove 8 along the vertical direction, and a gear 10 located in the sliding groove 3 is meshed on the rack 9. A rotating rod 11 is fixedly installed on the end of the gear 10 away from the center position of the bottom side of the base 1, and slides There is a turning hole 12 on the inner wall of the groove 3 away from the center position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com