Filament strip spot-tinning method

A technology of filaments and strips, which is applied in the direction of tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, poor consistency, and unfavorable effective production of products, so as to improve efficiency and reduce the number of spot welding , to ensure good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

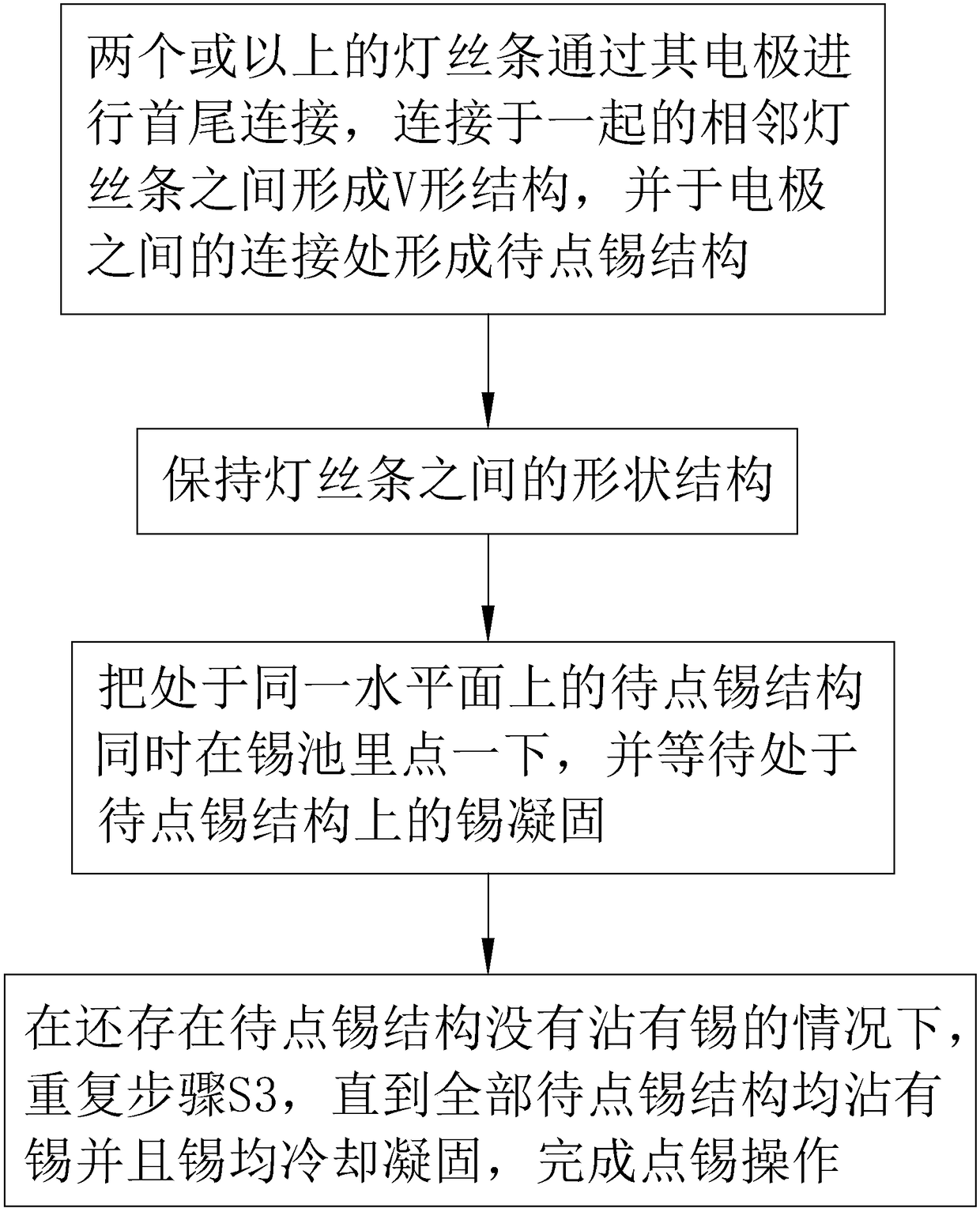

[0016] refer to figure 1 , the filament tin spot method of the present invention comprises the following steps:

[0017] S1. Two or more filament strips are connected end-to-end through their electrodes, and a V-shaped structure is formed between adjacent filament strips connected together, and a tin structure to be lit is formed at the connection between the electrodes;

[0018] S2, maintaining the shape and structure between the filament strips;

[0019] S3. Tap the tin structure to be spot on the same horizontal plane in the tin pool at the same time, and wait for the tin on the tin structure to be spot to solidify;

[0020] S4. In the case that the tin structure to be spot is not stained with tin, repeat step S3 until all the tin structures to be spot are stained with tin and the tin is cooled and solidified, and the tin spot operation is completed.

[0021] Specifically, by connecting the electrodes of the two filament strips, each two filament strips form a sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com