An automatic pallet cleaning device

An automatic cleaning and tray technology, applied in the direction of cleaning methods using gas flow, dust removal, cleaning methods and utensils, etc., can solve the problems of low work efficiency, high labor intensity, and unguaranteed cleaning quality, and achieve labor intensity Large size, less space occupation, and solve the effect of dust flying everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

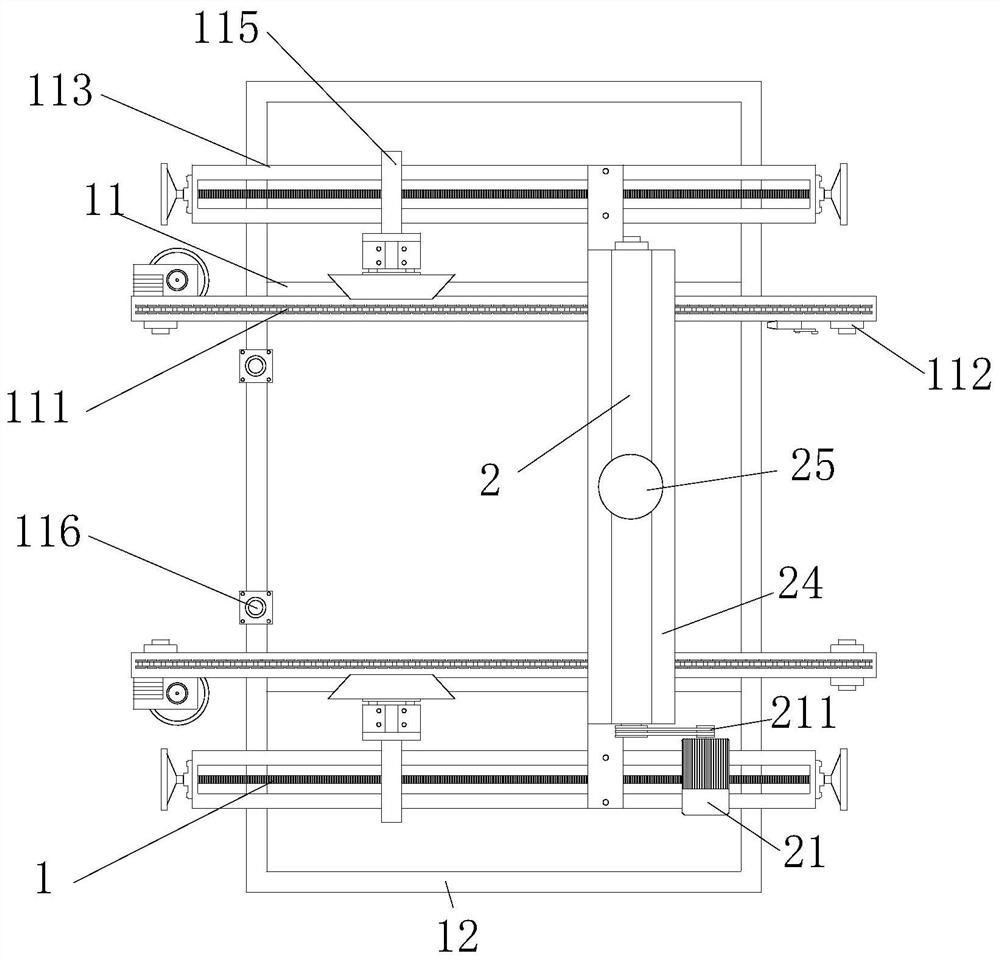

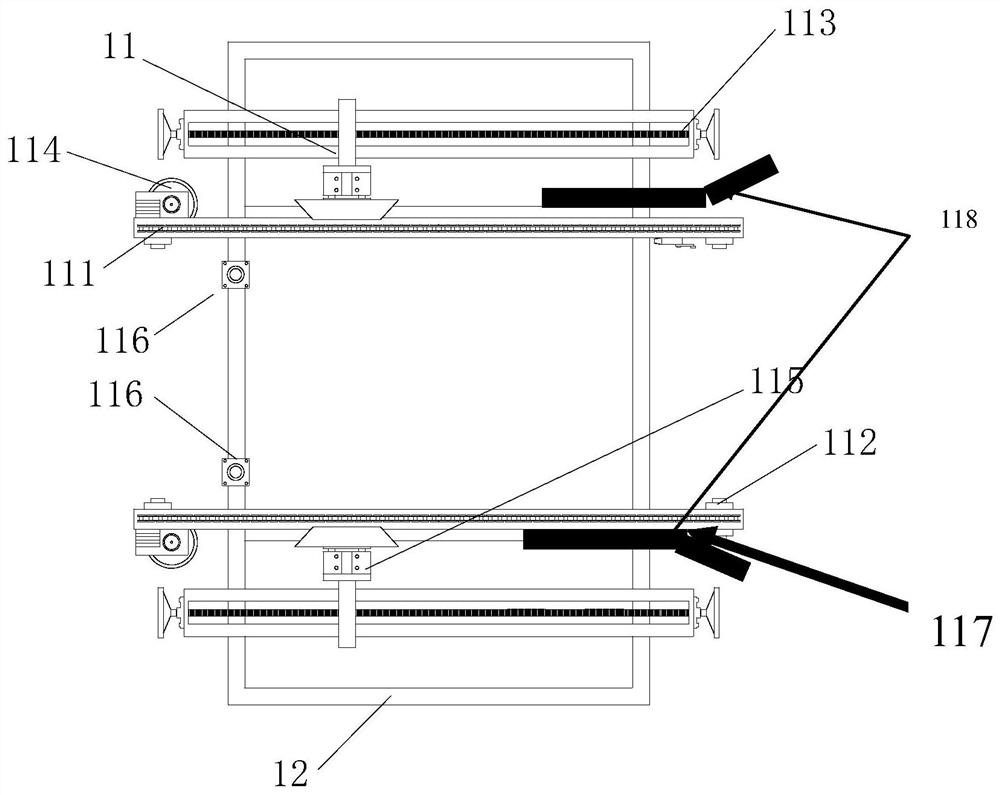

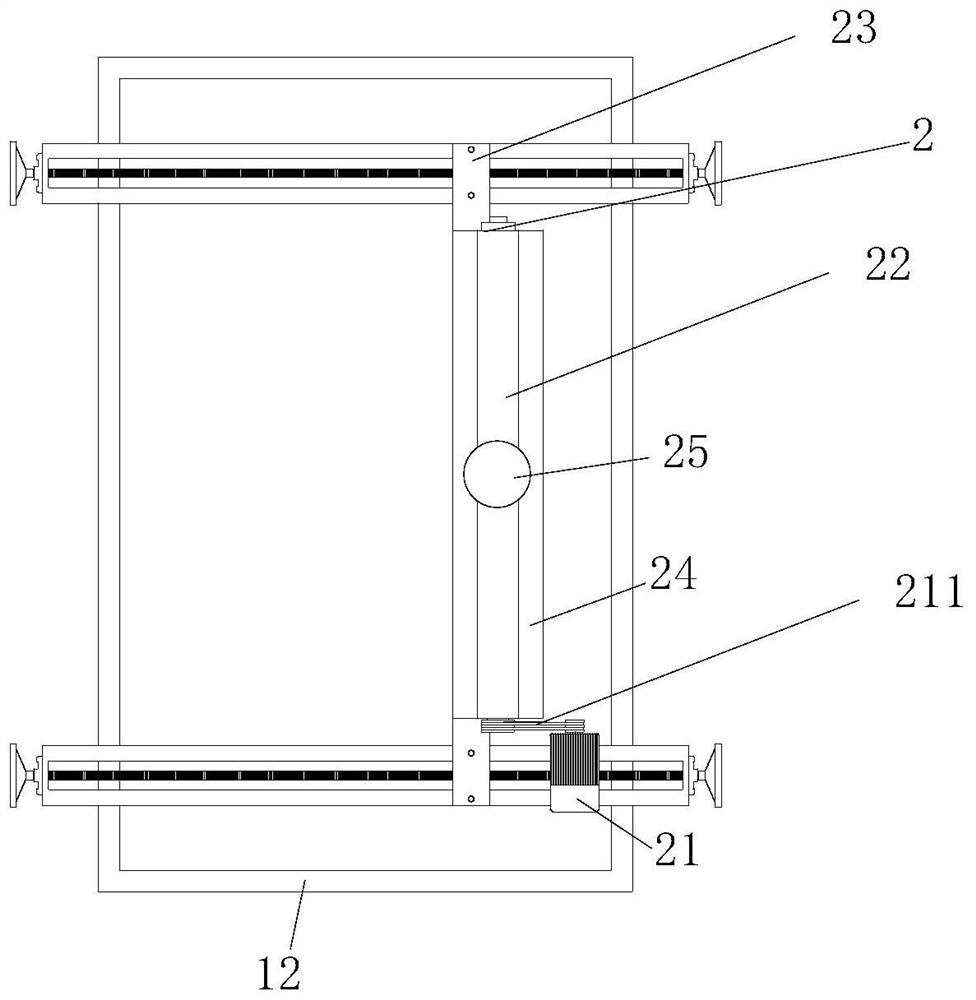

[0017] Embodiment 1 An automatic pallet cleaning device according to the present invention includes a pallet conveying mechanism 1 for conveying pallets to the cleaning area of the cleaning mechanism, a pallet cleaning mechanism 2 for cleaning debris on the surface of the pallet, and a pallet cleaning mechanism for controlling the entire cleaning mechanism. The controller of the device operation, one end of the pallet conveying mechanism 1 is used as the pallet placement end, and the other end passes through the cleaning area directly below the pallet cleaning mechanism 2 and then transported to the next station. The control end of the pallet conveying mechanism 1, The control ends of the tray cleaning mechanism 2 are respectively electrically connected to the signal output ends of the controller;

[0018] The pallet conveying mechanism 1 includes a conveying chain assembly 11 for conveying pallets and a frame 12 for installing the conveying chain assembly. The conveying chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com