A kind of regeneration method of Al2O3 supported platinum-tin dehydrogenation catalyst

A technology of dehydrogenation catalyst and aluminum oxide, which is applied in the direction of catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of loss of activity and achieve improvement Active, reduce energy waste, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

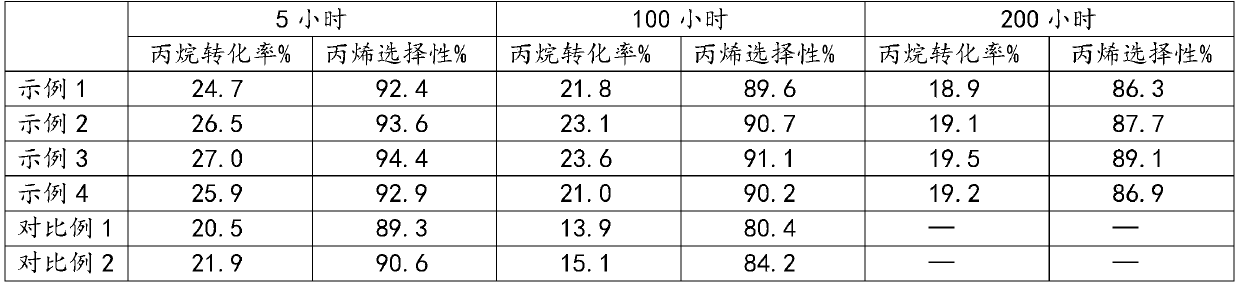

example 1

[0058] After the Al2O3-supported platinum tin propane dehydrogenation to propylene catalyst is deactivated (the conversion rate of propane is lower than 15% or the selectivity of propylene is lower than 85%), the catalyst is regenerated. Reduce the temperature of the catalyst bed to 400°C, and pass through the regeneration treatment gas, wherein the oxygen content is 0.5%, the chlorinating agent content is 5%, and the gas space velocity is 2000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 450°C, the oxygen content was raised to 3%, the chlorinating agent monochloromethane content was maintained at 5%, and the gas space velocity was 2000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 500°C, the oxygen content was raised to 8%, the chlorinating agent content was maintained at 5%, and the gas space velocity was 2000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 550°C, the oxygen content was rai...

example 2

[0061] After the Al2O3-supported platinum tin propane dehydrogenation to propylene catalyst is deactivated (the conversion rate of propane is lower than 15% or the selectivity of propylene is lower than 85%), the catalyst is regenerated. Lower the temperature of the catalyst bed to 400°C, and pass through the regeneration treatment gas, wherein the oxygen content is 0.5%, the chlorinating agent methylene chloride content is 5%, and the gas space velocity is 4000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 450°C, the oxygen content was raised to 3%, the chlorinating agent content was maintained at 5%, and the gas space velocity was 4000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 500°C, the oxygen content was raised to 8%, the chlorinating agent content was maintained at 5%, and the gas space velocity was 4000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 550°C, the oxygen content was rai...

example 3

[0064] After the Al2O3-supported platinum tin propane dehydrogenation to propylene catalyst is deactivated (the conversion rate of propane is lower than 15% or the selectivity of propylene is lower than 85%), the catalyst is regenerated. Lower the temperature of the catalyst bed to 450°C, pass through the regeneration treatment gas, wherein the oxygen content is 0.5%, the chlorinating agent monochloromethane and trichloromethane content are 5%, and the gas space velocity is 3000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 500°C, the oxygen content was raised to 3%, the chlorinating agent content was maintained at 5%, and the gas space velocity was 3000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 550°C, the oxygen content was raised to 8%, the chlorinating agent content was maintained at 5%, and the gas space velocity was 3000 -1 , treated for 10 hours; then the catalyst bed temperature was raised to 600°C, the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com