Milk making control method of food processing machine

A technology of a food processing machine and a control method, which is applied in the control/regulation system, timing control of the ignition mechanism, and temperature control by electric means, can solve the problems of affecting the use of the machine, easily producing scale, and increasing the cost, so as to reduce the cost of the machine. cost, the effect of improving machine performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

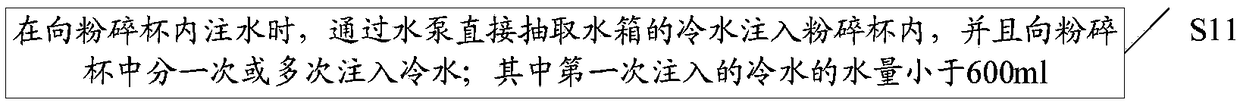

[0062] A pulping control method for a food processor, the food processor comprising: a motor, a crushing cup and a water tank, a heating device is provided at the bottom of the crushing cup, a crushing blade is provided inside the crushing cup, the water tank is connected to the crushing cup through a pipeline, and the pipe There is a water pump in the road; if figure 1 As shown, the method may include S11:

[0063] When pouring water into the crushing cup, the cold water from the water tank is directly drawn into the crushing cup through the water pump, and the cold water is injected into the crushing cup one or more times; the amount of cold water injected for the first time is less than 600ml.

[0064] In the embodiment of the present invention, based on the current food processors equipped with instant heating devices (such as instant heating heating tubes, instant heating chambers, etc.), the cost is too high, and scale is easy to grow in the instant heating chamber under...

Embodiment 2

[0067] On the basis of Embodiment 1, this embodiment further limits the number of times of injecting cold water and the number of pulping during the pulping process. Specifically, it can be determined according to different pulping capacity levels divided according to different volume numbers. Determine the number of times of water injection and the number of pulp discharge; wherein, different pulping capacity grades correspond to different times of water injection and pulp discharge.

[0068] Optionally, the method also includes:

[0069] According to the preset pulping capacity, the corresponding water injection times and pulping times are respectively used in the pulping process;

[0070] Wherein, when the pulping capacity is less than or equal to the preset first volume, pulping is carried out by means of one water injection and one pulp discharge;

[0071] When the pulping capacity is greater than the first volume and less than or equal to the preset second volume, multi...

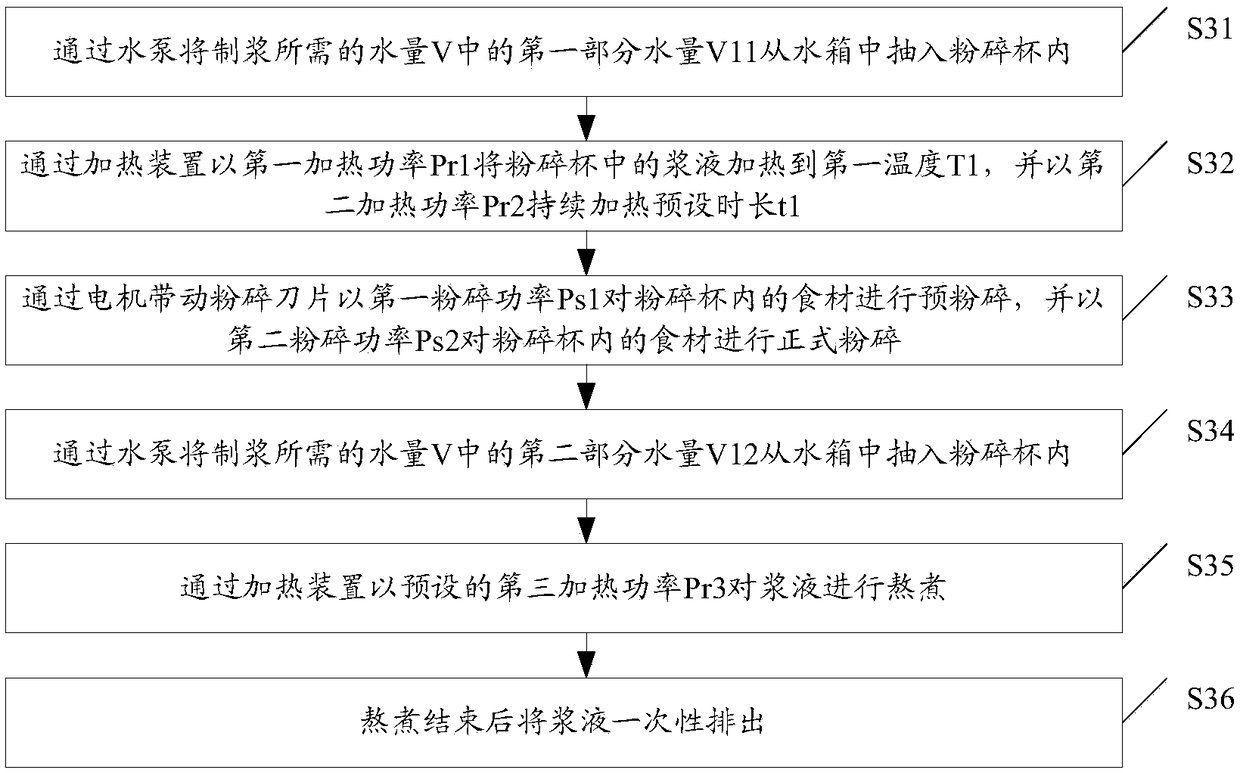

Embodiment 3

[0079] On the basis of the second embodiment, this embodiment provides a specific example of the pulping operation process when the pulping capacity is less than or equal to the first volume.

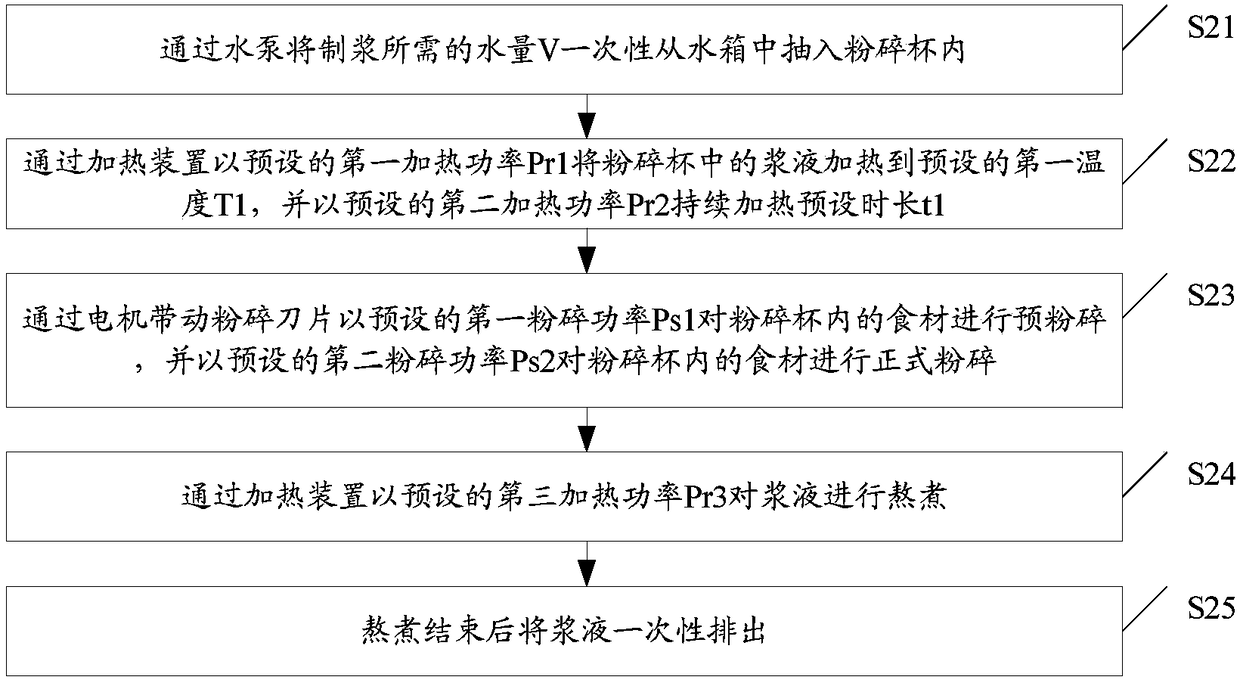

[0080] Optionally, as in figure 2 As shown, the method may also include: when the pulping capacity is less than or equal to the first volume, the pulping process may include steps S21-S25:

[0081] S21. Pump the water volume V required for pulping from the water tank into the crushing cup at one time through the water pump;

[0082] S22. Using the heating device to heat the slurry in the crushing cup to the preset first temperature T1 with the preset first heating power Pr1, and continue heating with the preset second heating power Pr2 for a preset time period t1; wherein, the first The first heating power Pr1 is greater than the second heating power Pr2;

[0083] S23. Use the motor to drive the crushing blade to pre-shred the ingredients in the crushing cup with the preset first cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com