Punching and seedling releasing mechanism of well-cellar transplanter

A transplanting machine, well cellar technology, applied in transplanting machinery, planting methods, excavation/covering trenches, etc., can solve the problem that the hole punching mechanism cannot adjust the depth of hole punching, cannot realize automatic seedling placement, and the plant spacing is not too good. Stability and other issues, to avoid uneven movement, balance weight, and good uprightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

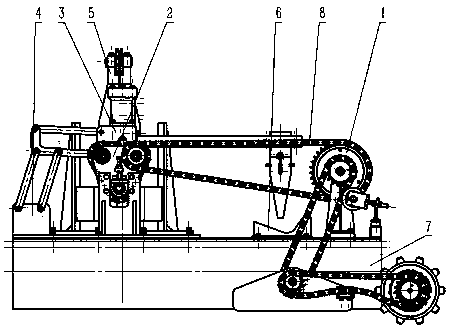

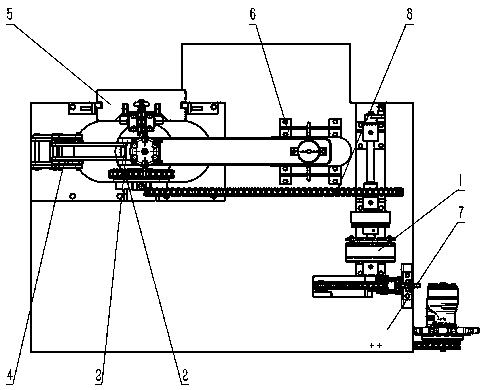

[0035] The present invention will be further described below in conjunction with the accompanying drawings. Depend on figure 1 , figure 2 It can be seen that a hole punching and seedling releasing mechanism of a pit-type transplanter includes: a power input assembly 1, a triangular chain sprocket assembly 2, a hole punching and seedling releasing assembly 3, a hole punching and seedling releasing support assembly 4, and a counterweight balance assembly 5 , duckbill opening profiling weldment 6, vehicle frame 7, transmission chain 8, etc., the power input assembly 1, the support assembly 4 for punching holes and releasing seedlings, the counterweight balance assembly 5, the The duckbill is opened and the profiling weldment 6 is fixedly installed on the vehicle frame 7 . The triangular chain sprocket assembly 2 is fixedly installed on the hole punching and seedling release support assembly 4 by bolts, and the hole punching and seedling release assembly 3 and the hole punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com