Rolling bearing fault prognostics method and system based on logistic regression and J divergence

A logistic regression and rolling bearing technology, which is applied in mechanical bearing testing and other directions, can solve problems such as inability to accurately evaluate the operating state of bearings, and achieve the effect of high accuracy, good robustness, and strong real-time performance of state evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

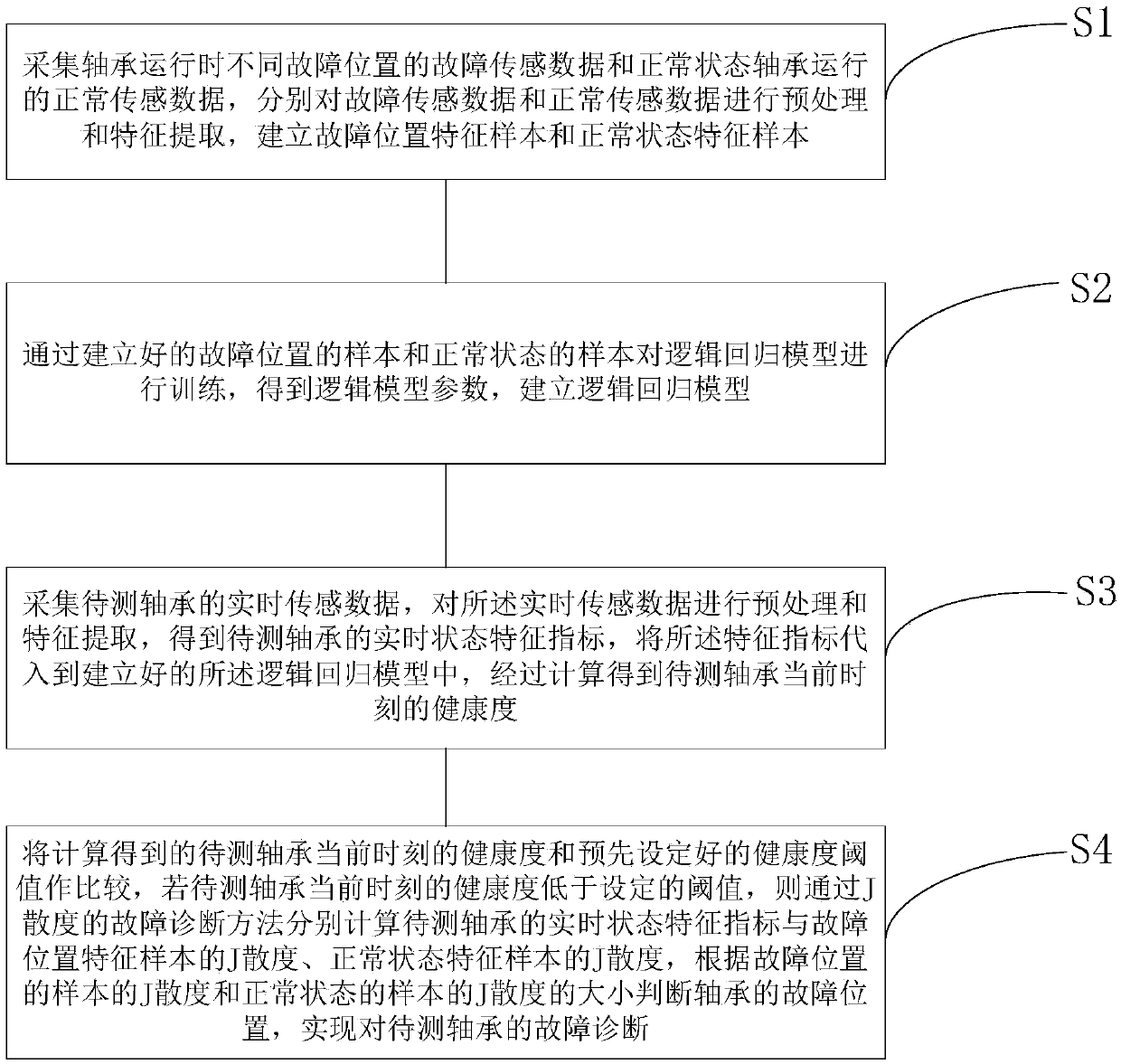

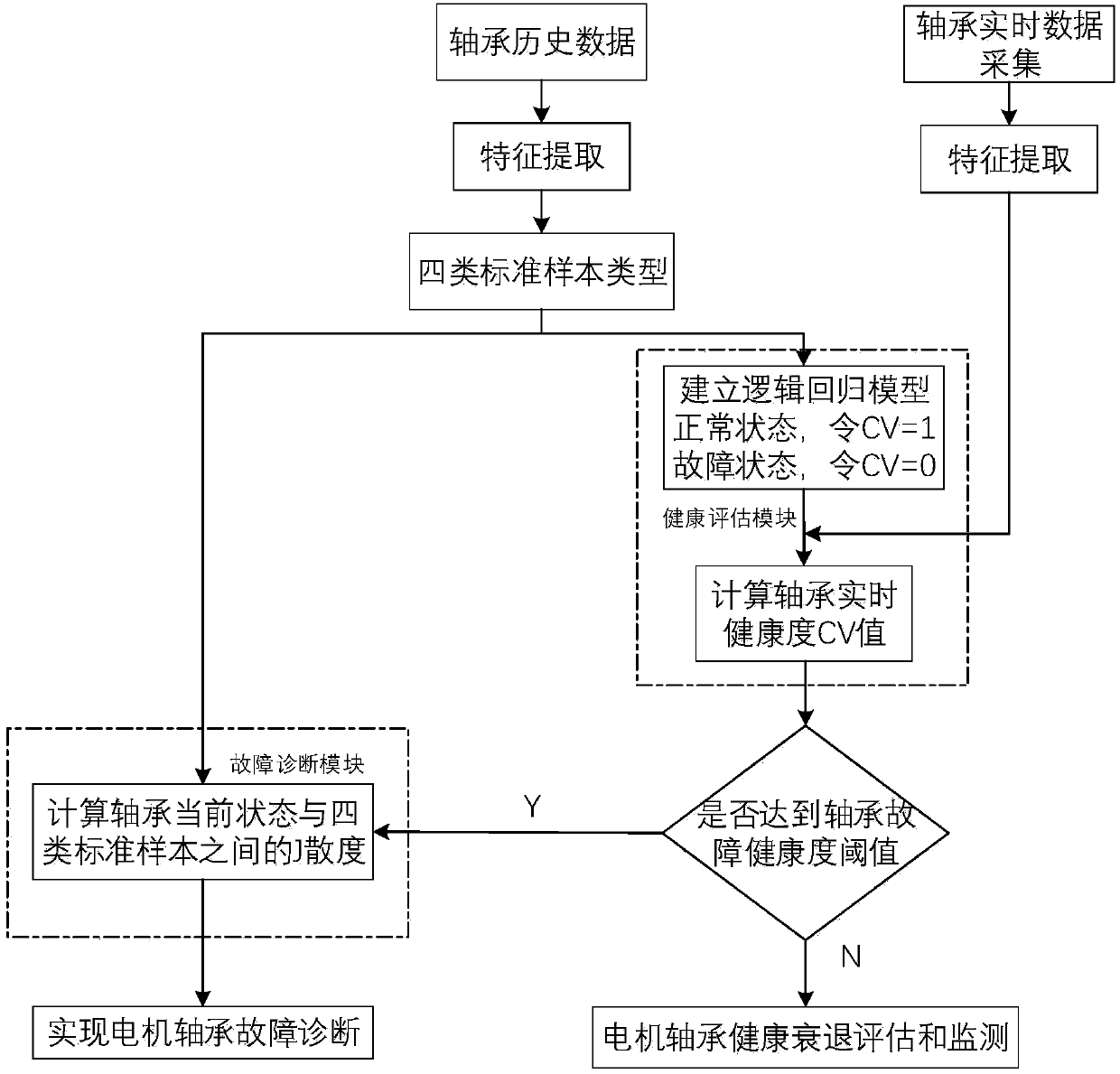

[0058] The method of the present invention is explained in conjunction with specific data and drawings. In this embodiment, three types of fault sensing data are used as examples to illustrate. The specific device diagram is shown in the accompanying drawings. figure 2 As shown, a fault prediction method for rolling bearings based on logistic regression and J divergence includes the following steps:

[0059] Step 1: Collect three kinds of fault sensing data at different fault positions during bearing operation and normal sensing data of bearing operation in normal state, respectively perform preprocessing and feature extraction on the three kinds of fault sensing data and normal sensing data, and establish three types of fault sensing data and normal sensing data. A fault location feature sample and a normal state feature sample;

[0060] Step 2: Train the logistic regression model through the established samples of the three fault locations and the samples in the normal stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com