Dual reactive gas driven high-speed launching system

A gas-driven, launch system technology, applied in the direction of compressed air guns, weapons without explosives, offensive equipment, etc., can solve the problems of high price, low gas density, and rapid decrease in efficiency, and achieve simple structure, increased energy density, and increased initial The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it does not imply any limitation to the content of the present invention.

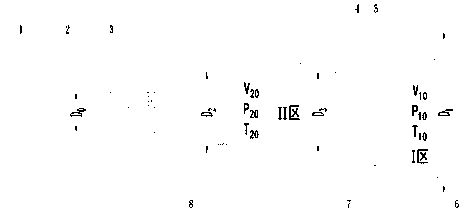

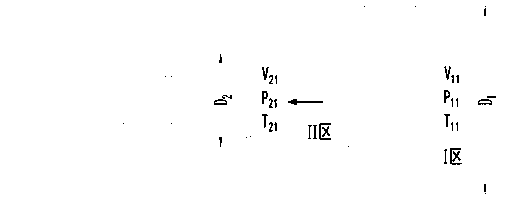

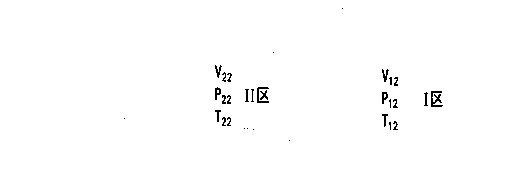

[0021] Such as figure 1 , a dual-reaction gas-driven high-speed launch system, comprising a launch tube 1 with projectiles 2, a reaction chamber, a diaphragm 3 located between the reaction chamber and the launch tube 1, characterized in that a piston 7 is housed in the reaction chamber, The piston 7 isolates the reaction chamber into two regions, the reaction chamber I zone 5 and the reaction chamber II zone 4, wherein the diaphragm 3 is located at the end of the reaction chamber II zone 4, and the reaction chamber I zone 5 is equipped with an ignition element 6, and the reaction chamber II Ignition element 8 is also housed in zone 4, deflagration is filled in zone 5 of reaction chamber I, and deflagration is also filled in zone 4 of reaction chamber II.

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com