Feeder provided with bionic sharkskin placoid scale structure and resistance reducing particles and manufacturing method

A manufacturing method, shark skin technology, applied in the application field of engineering bionic technology, can solve problems such as high power of the feeding motor, wear of the feeding mechanism, burning of the feeding motor, etc., to reduce wear noise, reduce equipment power loss, and ensure The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

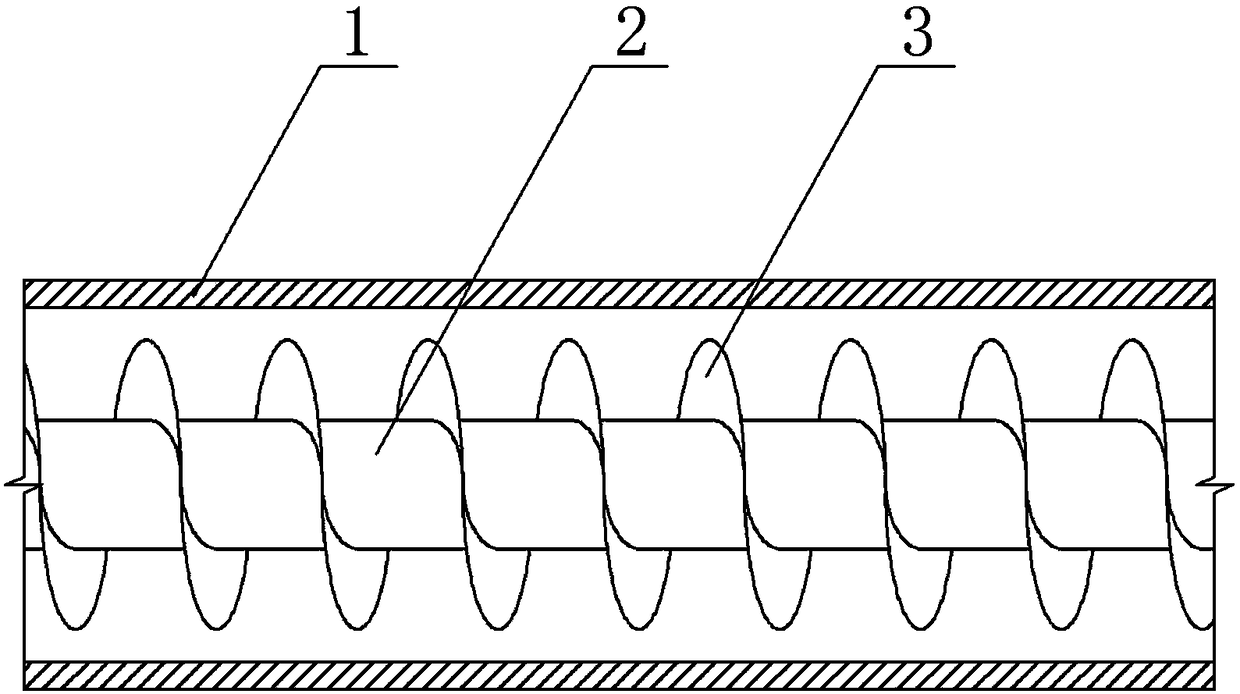

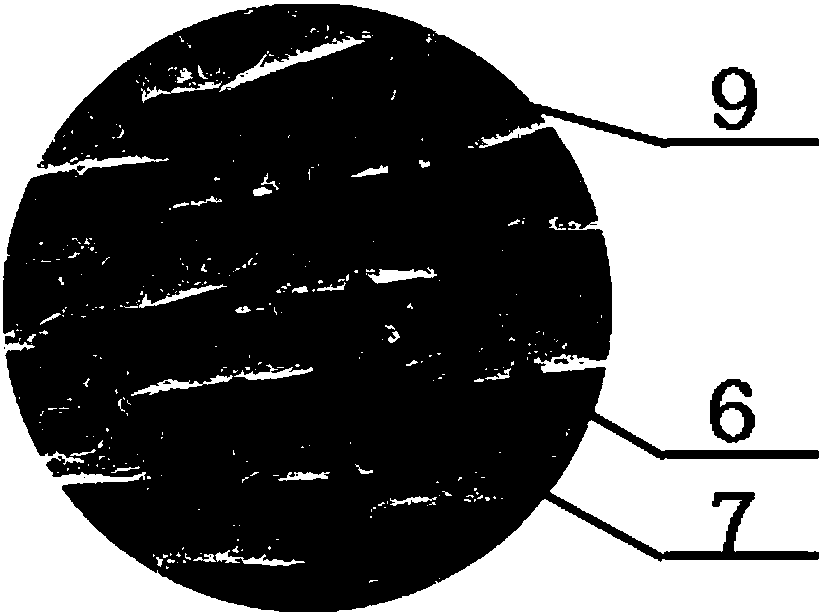

[0060] Such as figure 1 figure 2 As shown, a feeder with a bionic sharkskin shield scale structure and drag-reducing particles includes a housing 1 and a screw 2, the screw 2 includes a blade 3, and the surface of the blade 3 is provided with a bionic sharkskin shield scale structure and drag reduction Particles, the bionic shark skin shield scale structure is the same as the shield scale structure, and the drag reduction particles are raised particles. The shield scale structure distributed on the surface of the blade 3 includes continuously distributed shield scales B9, drag reducing particles C6 are distributed on the surface of the shield scales B9, and drag reducing particles D7 are distributed between the shield scales B9.

[0061] A method for manufacturing a feeder with a bionic sharkskin shield scale structure and drag-reducing particles, comprising the following steps:

[0062] a. Preparation of shark shield phosphorus biological template: intercept 50×50mm blue s...

Embodiment 2

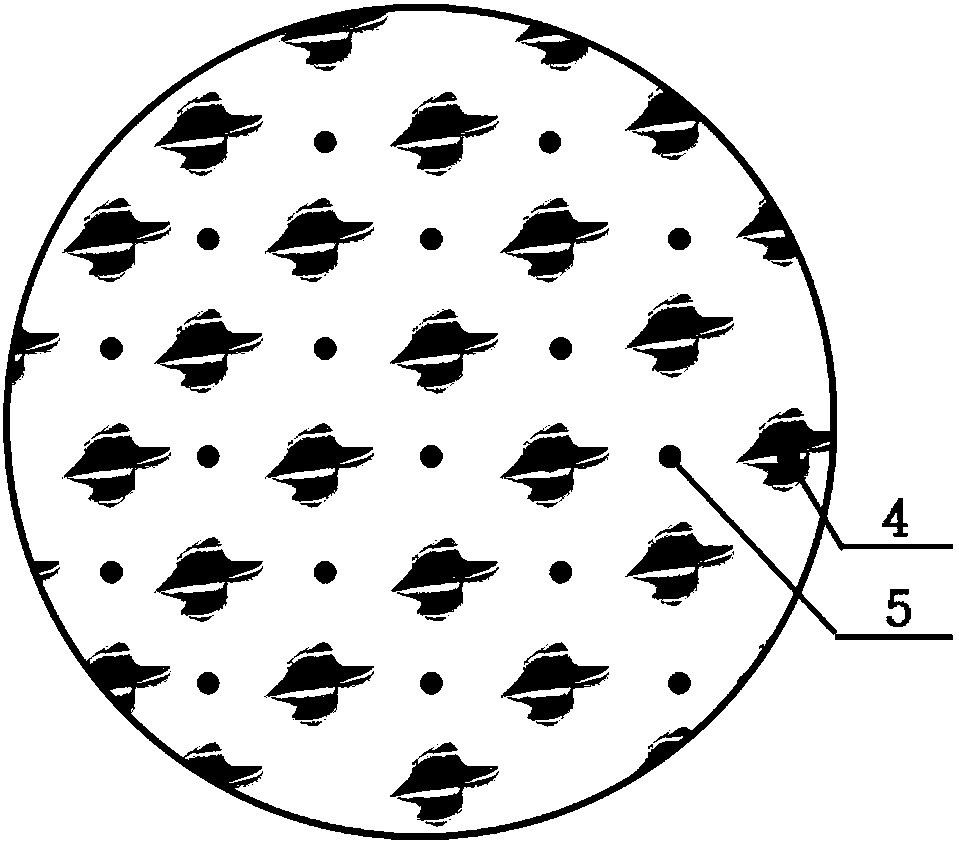

[0067] Such as image 3 As shown, in this embodiment, the shield scale structure includes shield scales A8 distributed in a staggered manner, drag reducing particles A4 are distributed on the surface of the shield scales A8, and drag reducing particles B5 are distributed between the shield scales A8.

[0068] A method for manufacturing a feeder with a bionic sharkskin shield scale structure and drag-reducing particles, comprising the following steps:

[0069] The biomass briquettes are formed, the particle size of the wood powder is controlled at about 30 mesh, and a single-pipe screw feeder with a shaft is used for feeding. In addition, in a self-made vacuum hot press, a polymethyl methacrylate (PMMA) plate was used as a substrate, and 150×300mm shark skin scales were spread on it with the face down and flattened with a plate supplemented by an air cushion; the temperature was raised under vacuum conditions. To the glass transition temperature (Tg) of PMMA (Tg) 105°C and kee...

Embodiment 3

[0072] Such as Figure 4 As shown, in this embodiment, the shield scale structure includes staggered distribution of shield scales A8 and continuous distribution of shield scales B9, drag reducing particles A4 are distributed on the surface of shield scales A8, and drag reducing particles B5 are distributed between shield scales A8 ; Drag-reducing particles C6 are distributed on the surface of the shield scale B9, and drag-reducing particles D7 are distributed between the shield scales B9.

[0073] In some rural areas, many waste straws and agricultural and forestry wastes in the fields are burned on site, which pollutes the environment and wastes resources. Therefore, they can be further processed to obtain biomass scraps, mixed with corn stalks and branches, and the length of scraps is about Below 5mm, equivalent diameter below 2mm, use shaftless screw feeder for feeding. Using high-precision electron microscope and scanning electron microscope to observe the biological tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com