Device convenient for moving light building wallboard

A technology for construction and wall panels, which is applied in the field of devices for moving light-weight building wall panels. It can solve the problems of uneven moving speed of transport panels, back and forth sliding of wall panels, and uneven ground, so as to protect the quality of side walls and avoid vibration damage. damage and reduce stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

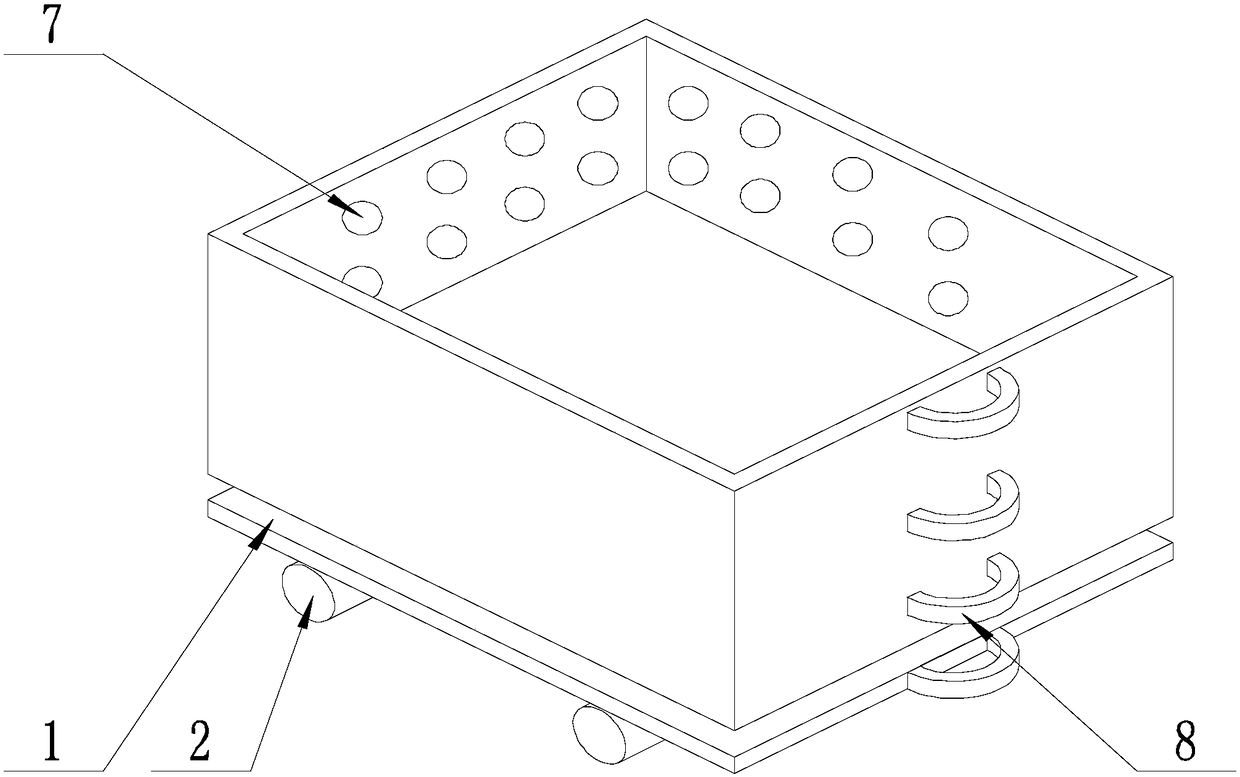

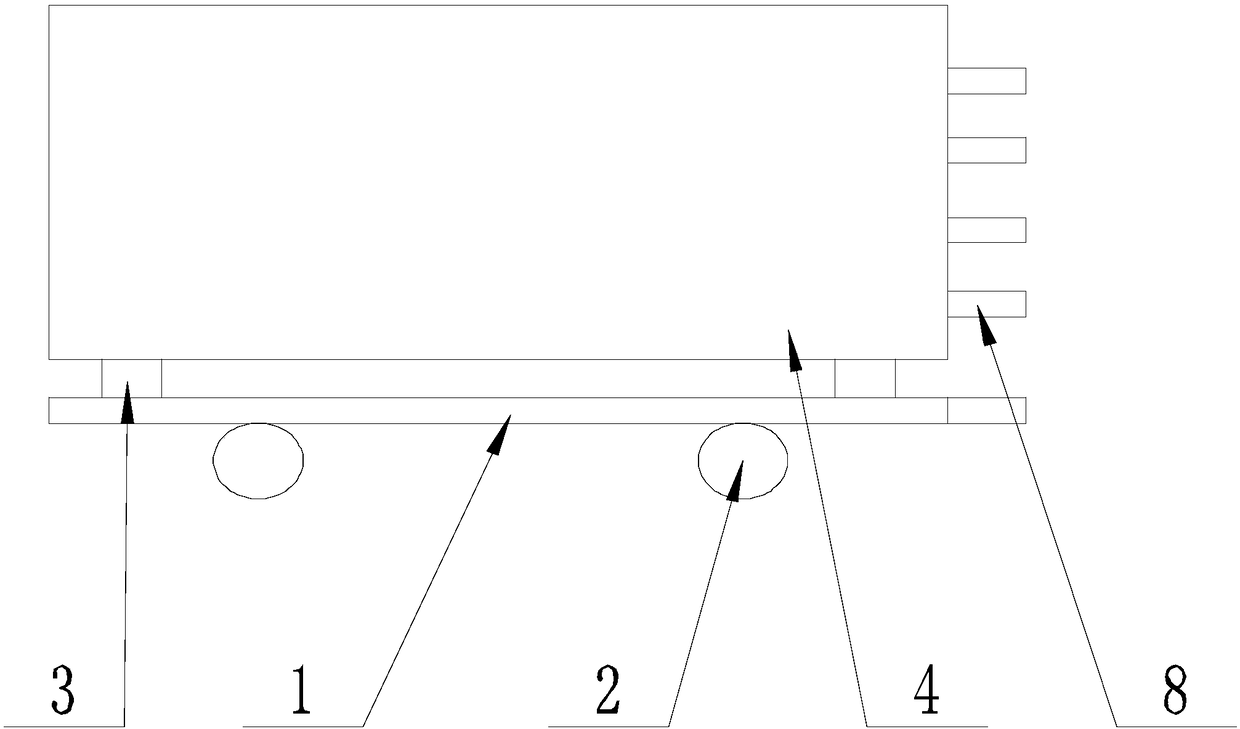

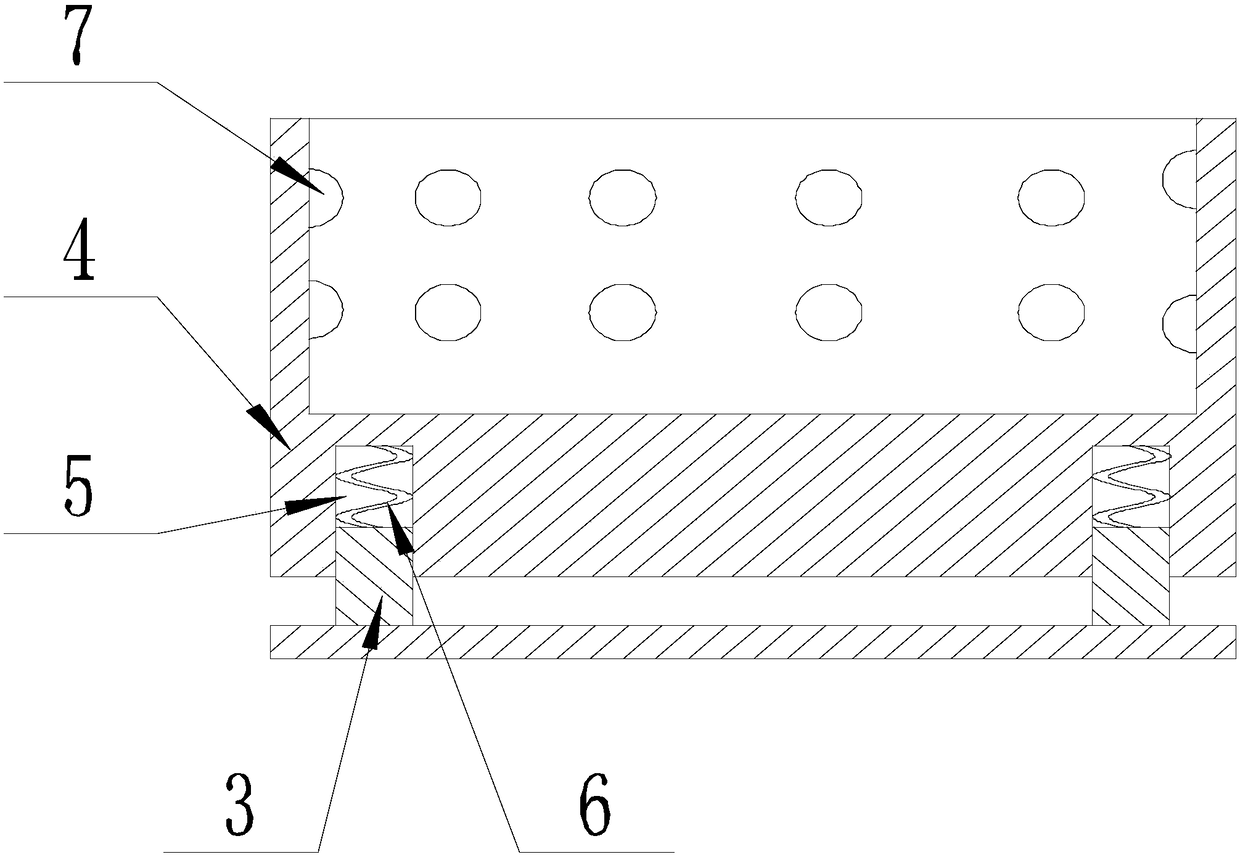

[0032] like Figure 1-Figure 3 As shown, the present invention is convenient to move the device of light-weight building wallboard, comprises the roller 2 that connects successively, transport plate 1 and bearing box 4, and described bearing box 4 is positioned at the top of transport plate 1, on the lower surface of bearing box 4 Several installation holes 5 are provided, the axes of the installation holes 5 are perpendicular to the horizontal plane, damping springs 6 are arranged in the installation holes 5, and several limit rods 3 are arranged on the upper surface of the transportation board 1 , the axis of the limiting rod 3 is perpendicular to the horizontal plane, one end of the limiting rod 3 is connected with the upper surface of the transport plate 1, and the other end of the limiting rod 3 is inserted into a mounting hole 5 respectively, and is connected with the damping spring 6 connect.

[0033] Before transportation, the lightweight building wall panels are hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com