A horizontal moving device for laser testing of wall inclination

A technology of moving devices and inclinations, applied in active optical measuring devices, measuring devices, measuring instruments, etc., can solve problems such as difficult to measure distances, difficult to obtain detection results, difficult to level rulers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

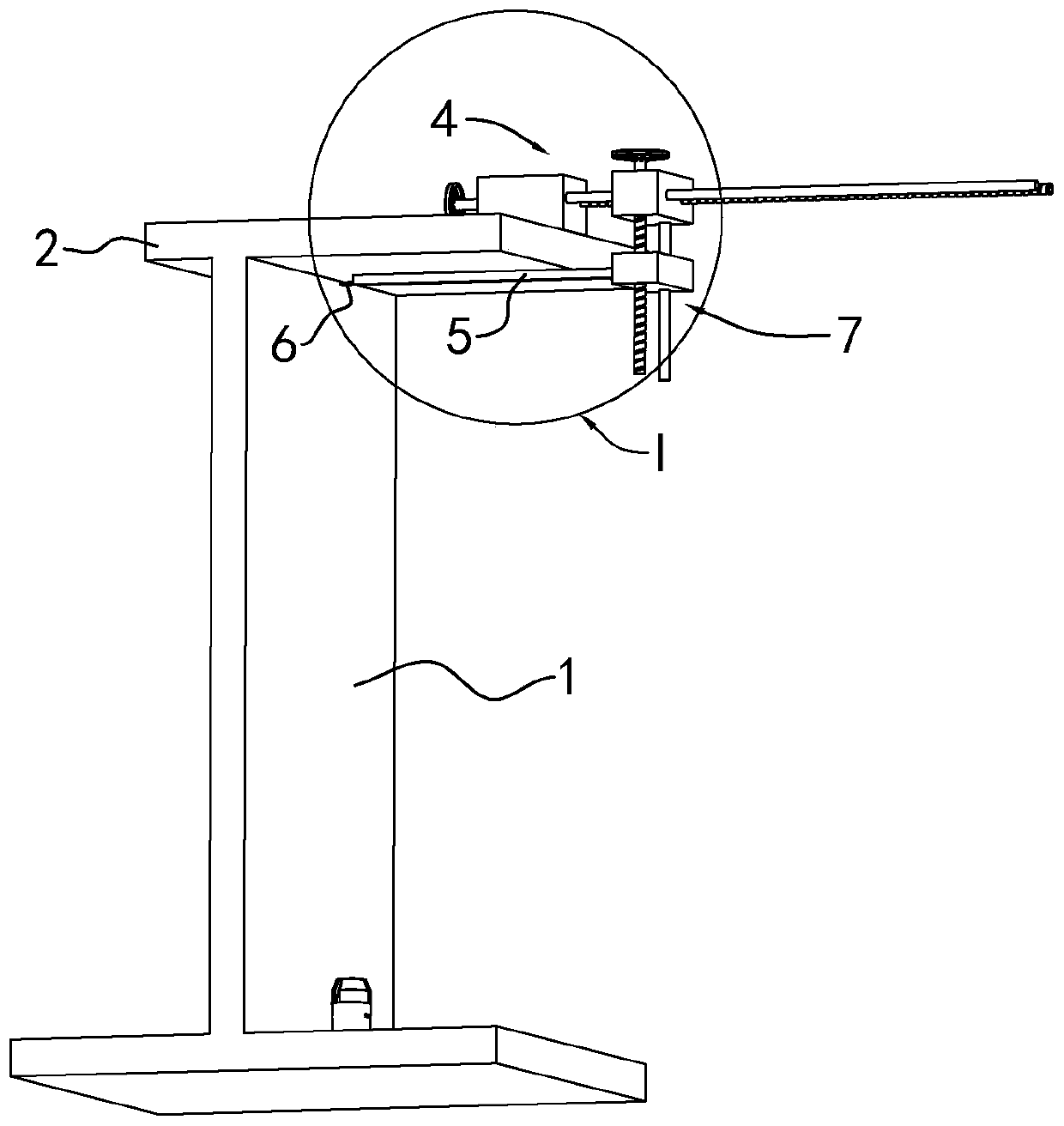

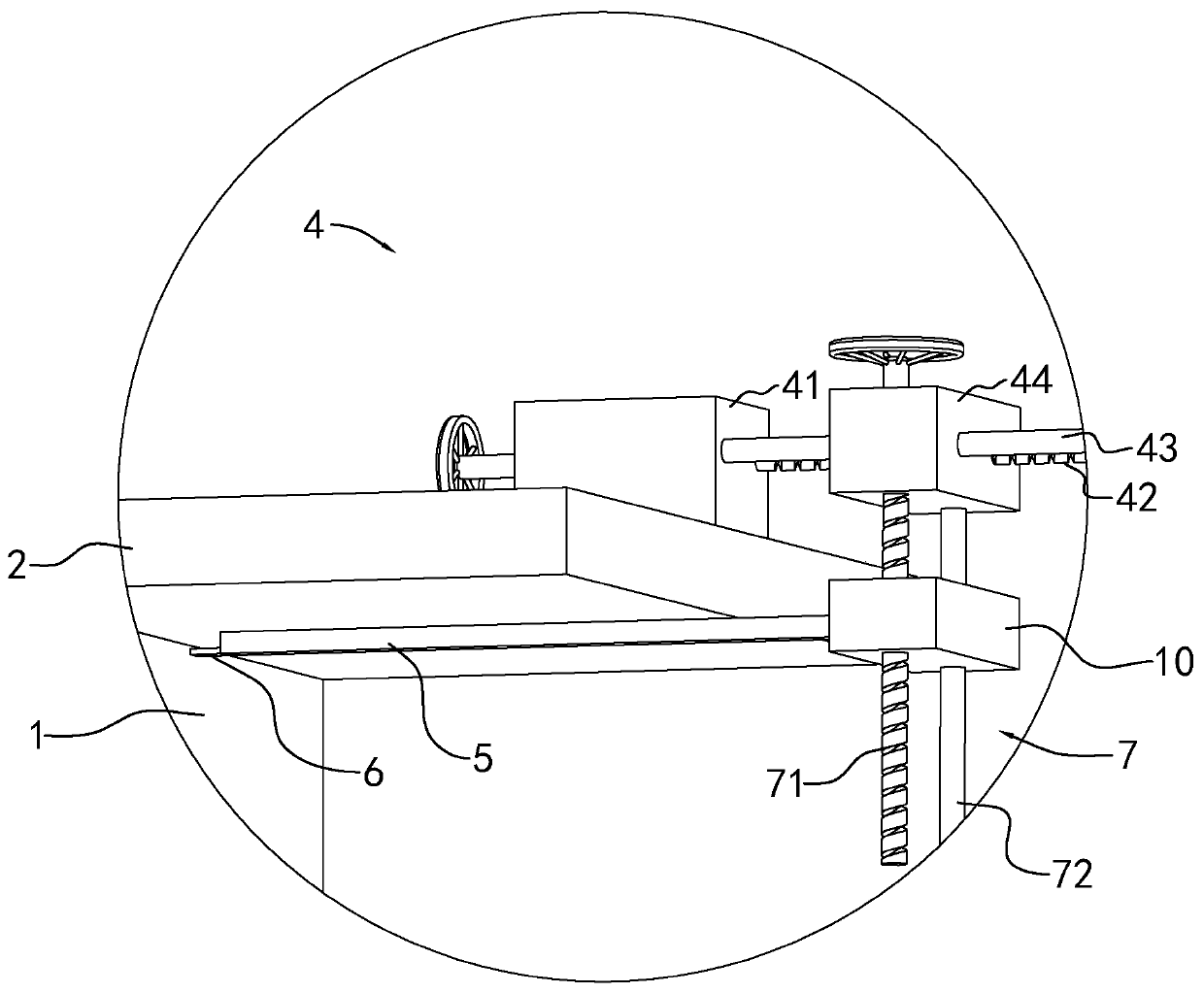

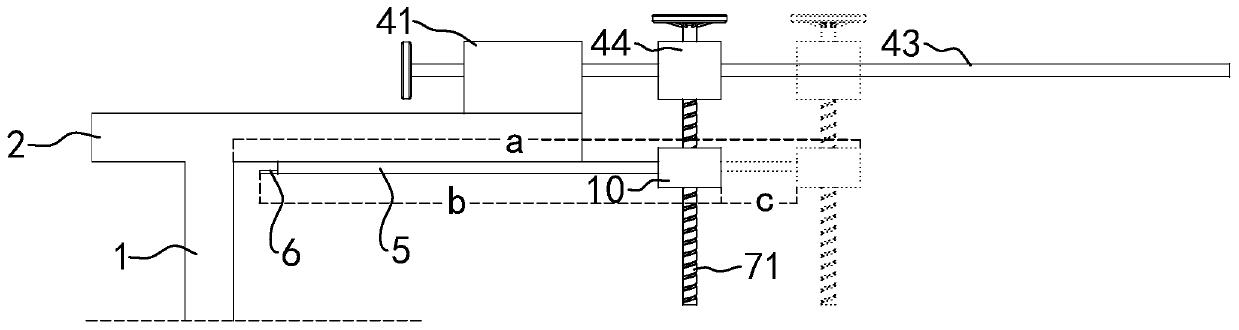

[0033] Embodiment 1, a kind of horizontal moving device for the laser test of the inclination of the wall body 1, see figure 1 and 2 , including the first lead screw structure 4, the first lead screw structure 4 includes a base 41 that can be placed on the platform 2 and auxiliary parts arranged on the base 41, a level can be installed on the top of the base 41, and a level can be installed on the observation level The position of the air bubble to adjust the base 41 to the level.

[0034] Auxiliary parts comprise two horizontal screw mandrels 42 and guide rods 43 that are arranged in parallel, wherein the smooth section of the left part of the screw mandrel 42 passes through the base 41 and rotates to fit. In order to improve the smoothness of rotation, the screw mandrel 42 and Bearings are arranged between the bases 41; the left end of the screw rod 42 is fixedly connected with the base 41 coaxially with a hand wheel, and the right part is a threaded part, which is threade...

Embodiment 2

[0038] Embodiment 2, a horizontal moving device for the laser test of the inclination of the wall 1, combined with Figure 4 The difference from Example 1 is that the end of the connecting rod 5 away from the guide block 44 is fixedly connected with an inclined mirror 8, and the laser emitted by the laser marking instrument 3 is irradiated on the mirror 8, which is difficult to observe due to the irradiation on the upper side. Whether the laser has entered the mirror 8, the mirror 8 is set to be inclined, the reflection of the mirror 8 can increase and change the laser path, so that the final landing point of the laser is the ground, as long as the staff downstairs observe the laser appearing on the ground, Then it indicates that the laser light enters into the mirror surface 8 .

[0039]In addition, in order to be able to achieve the completion of the test by only one staff member in this embodiment 2, the mirror surface 8 is installed at an angle of 45° with the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com