Lifting clamping mechanism for car gear shaft maintenance

A clamping mechanism and gear shaft technology, applied in the direction of lifting frame, workpiece clamping device, lifting device, etc., can solve the problems of easy sliding, low efficiency, low clamping firmness, etc., and achieve convenient maintenance and firm clamping and fixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

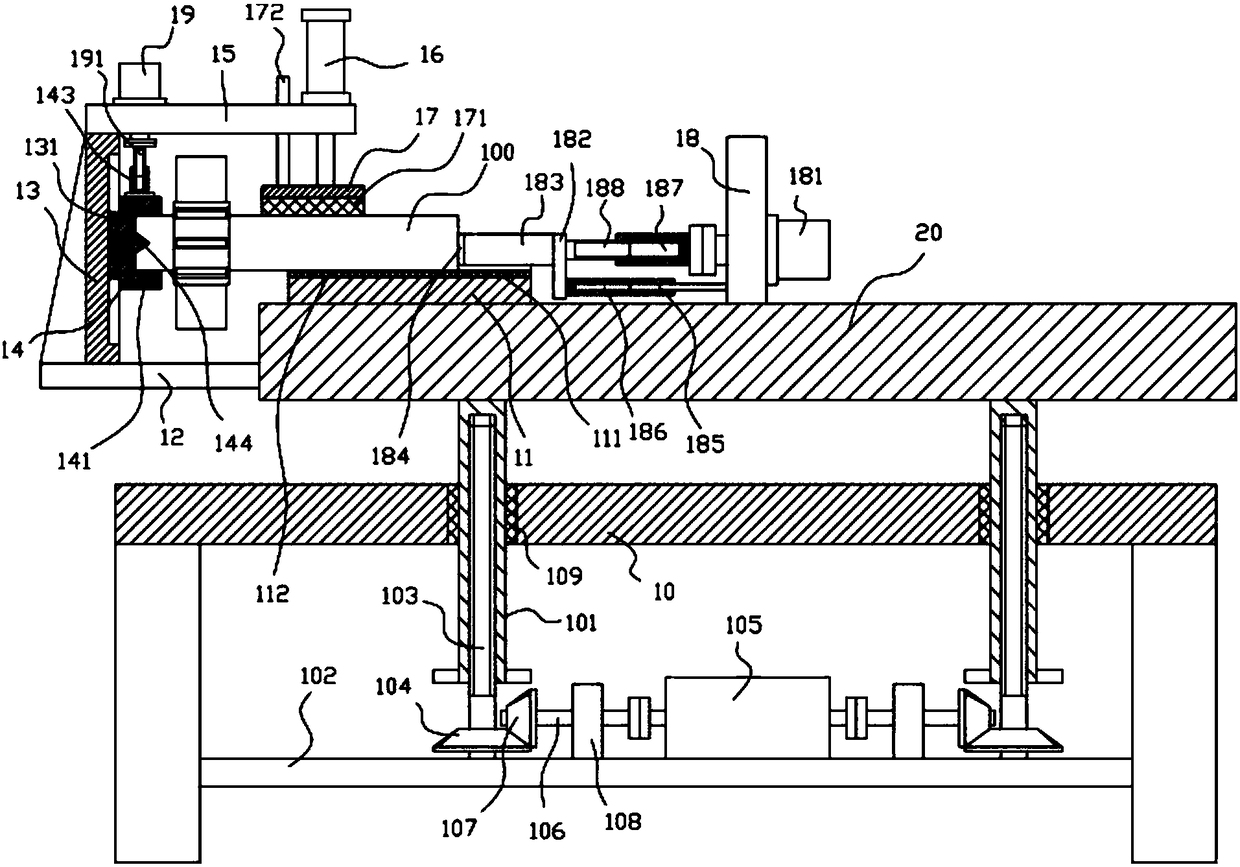

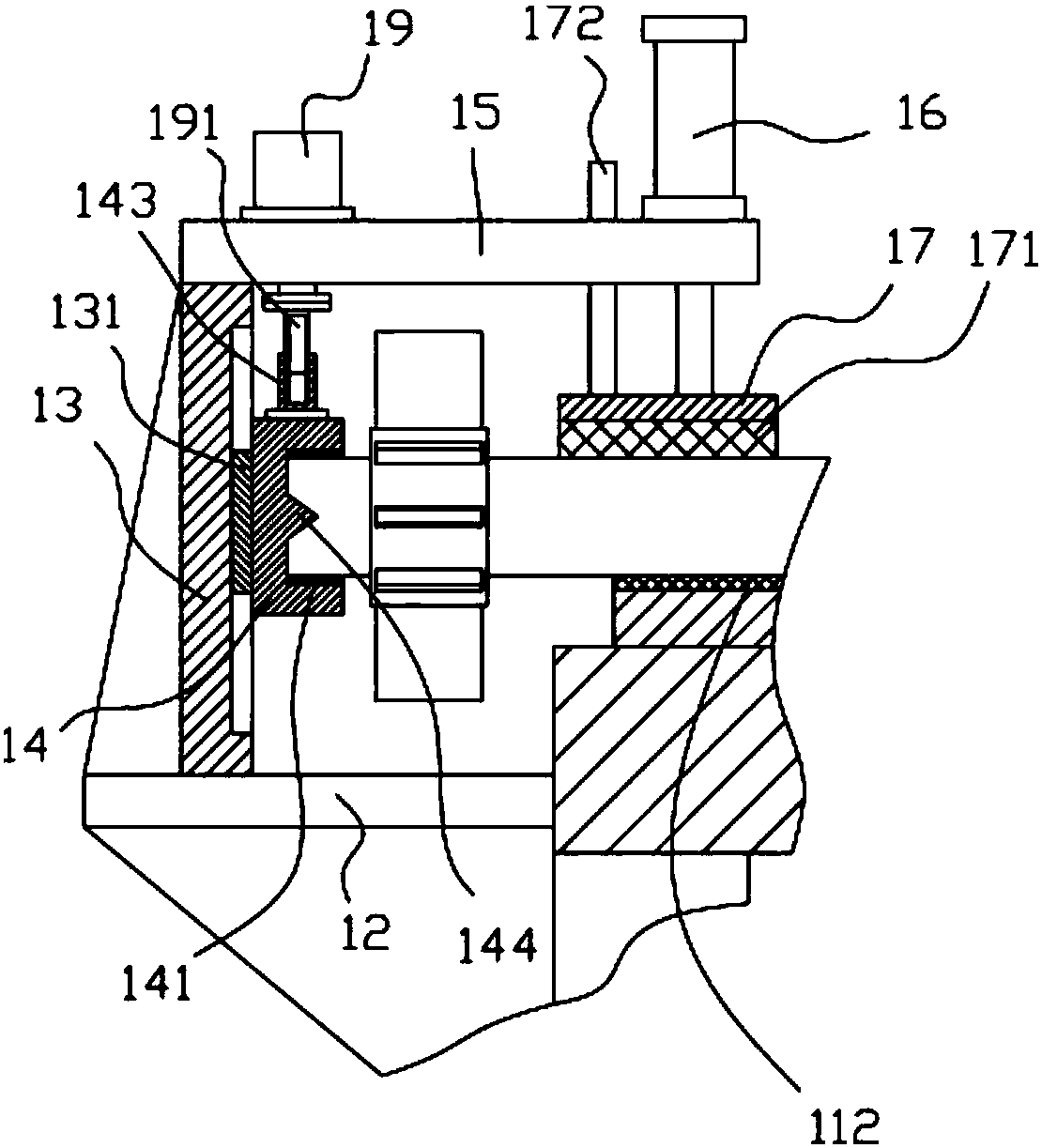

[0021] Example: see Figure 1 to Figure 2 As shown, a lifting clamping mechanism for automobile gear shaft maintenance includes a frame 10 and a lifting main board 20. The lifting main board 20 is located above the top plate of the frame 10, and the top plate of the frame 10 has two vertical inserts. Straight adjustment screw sleeve 101, the top end of the vertical adjustment screw sleeve 101 protrudes from the top surface of the top plate of the frame 10 and is fixed on the bottom surface of the lifting main board 20, and the lower horizontal fixing plate is fixed on the lower side wall of the leg of the frame 10 102. Both sides of the top surface of the lower horizontal fixing plate 102 are hinged with lifting vertical screws 103, the upper part of the lifting vertical screw 103 is screwed in the vertical adjustment screw sleeve 101, and the lower part of the vertical adjustment screw sleeve 101 is in the frame 10. Below the top plate of the vertical screw 103, a transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com