Tube bundle reaction and rectification integration apparatus

A technology of reactive distillation and reaction device, which is applied in distillation separation, chemical instruments and methods, distillation adjustment/control, etc., can solve the problems of catalyst coking, difficulty in refining, affecting product quality and yield, etc., and achieves reduction of by-products. The effect of generating, avoiding secondary reactions, and avoiding coking inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

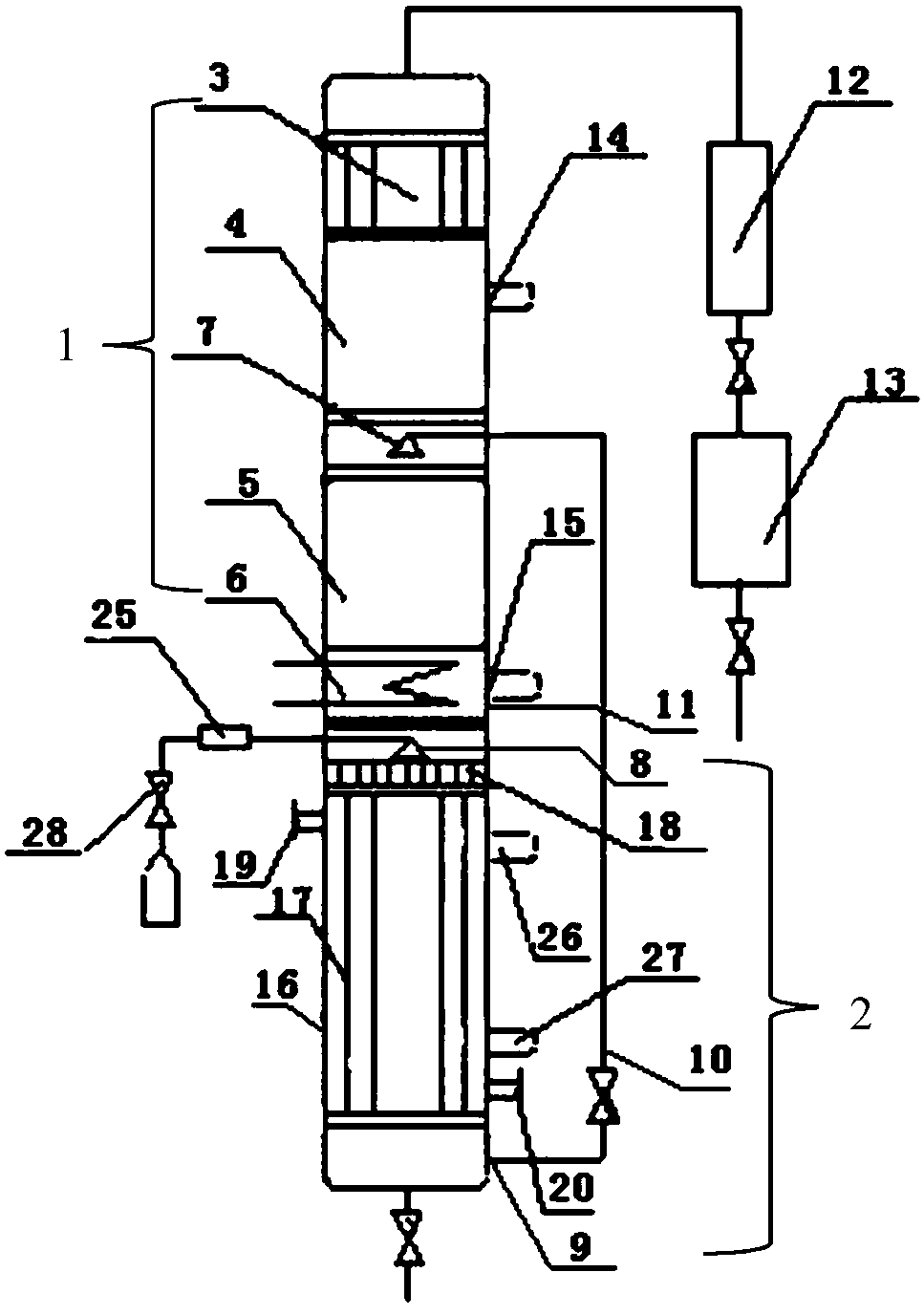

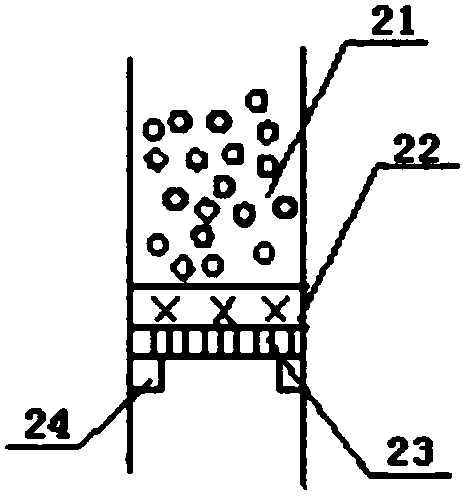

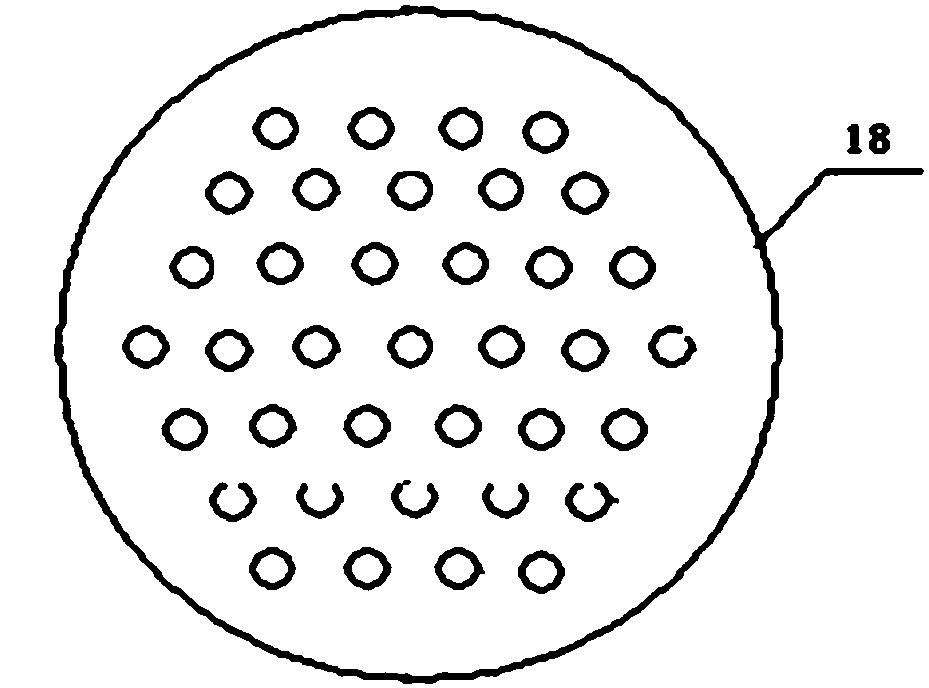

[0013] Such as figure 1 As shown, the tube bundle reaction distillation integrated device of the present invention includes a rectification device 1 and a tube bundle reaction device 2 integrated up and down.

[0014] The rectification device 1 includes an internal reflux condenser 3, a rectification section 4, a stripping section 5 and a coil heater 6 from top to bottom, and the internal reflux condenser 3 is also connected to an external condenser 12 and connected to the external condenser. The collection tank 13 connected with the condenser 12, the internal reflux condenser 3 and the external condenser 12 are controlled by using a cooling medium. The whole rectification device 1 supplements the heat and controls the temperature through the coil heater 6 . A first thermocouple 14 and a second thermocouple 15 are respectively installed at the upper and lower ends of the rectification device 1 for temperature measurement. A first feed port 7 is provided between the rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com