Wet mixing granulator, and solid preparation production line applying wet mixing granulator

A technology of wet mixing and granulator, which is applied in the direction of granulation in static tanks/tanks, can solve the problems such as the interference of scraper movement, and achieve the effect of full utilization of materials, simple structure and convenient cleaning.

Active Publication Date: 2018-06-15

HANGZHOU GUOGUANG PHARMA

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] This method can only scrape powder on the part of the pot body, and the structure of the existing wet mixing granulator is generally the same as the patent disclosed in China with the publication number CN2745642Y. The movement of the flakes causes interference

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

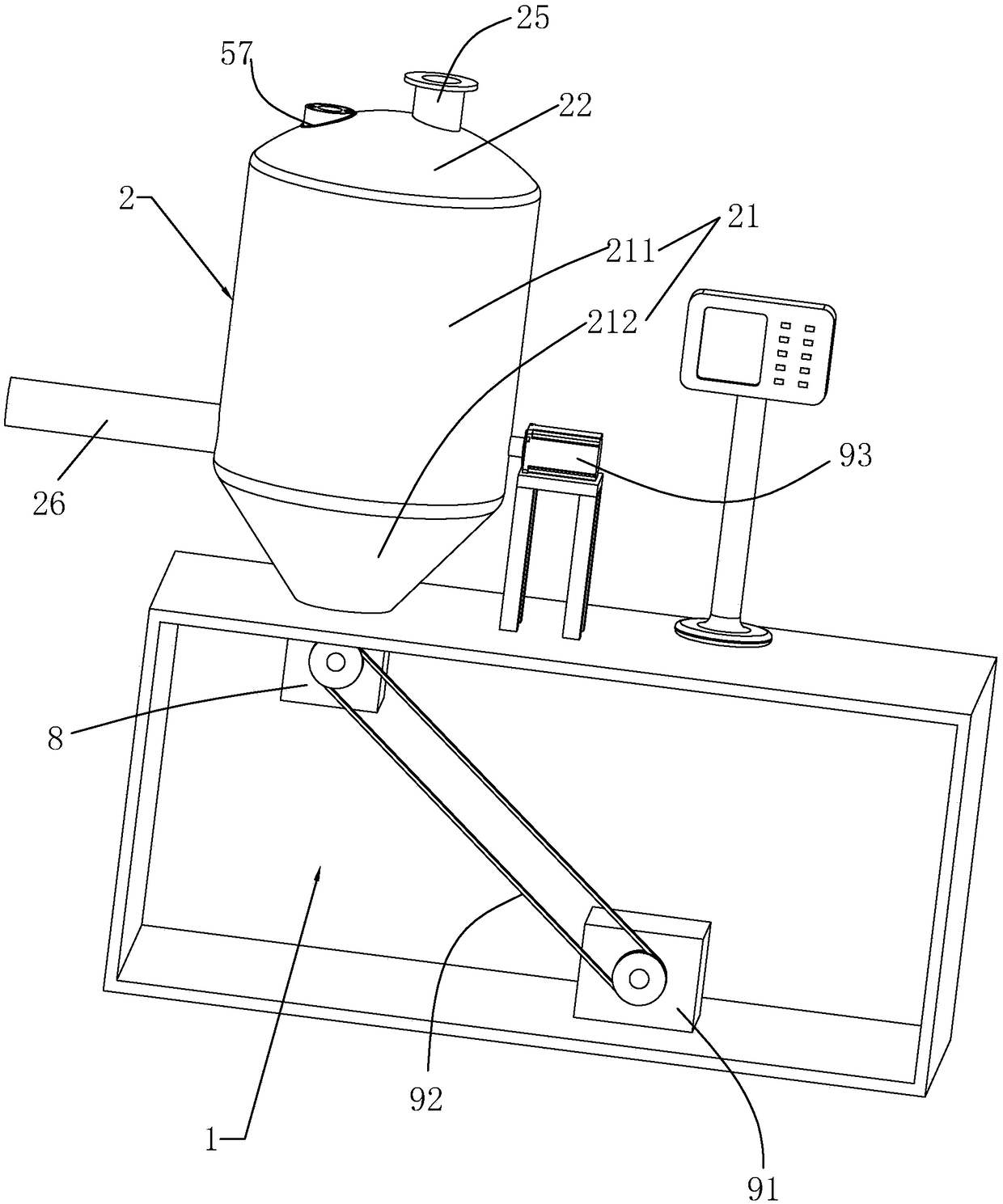

[0047] Embodiment 2: A production line for solid preparations, comprising a pulverizer, a mixer, embodiment 1, and a coating machine connected in sequence.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

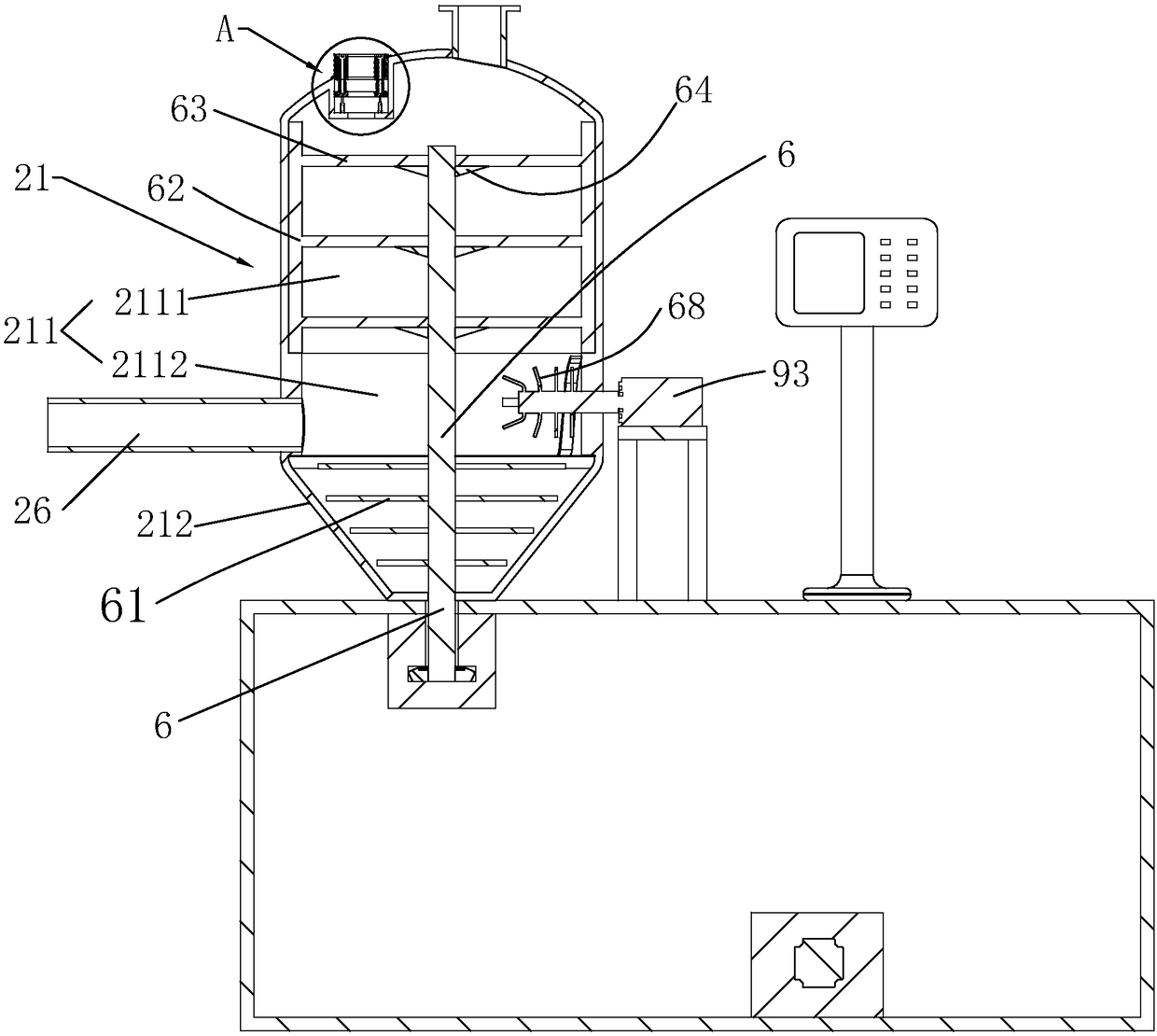

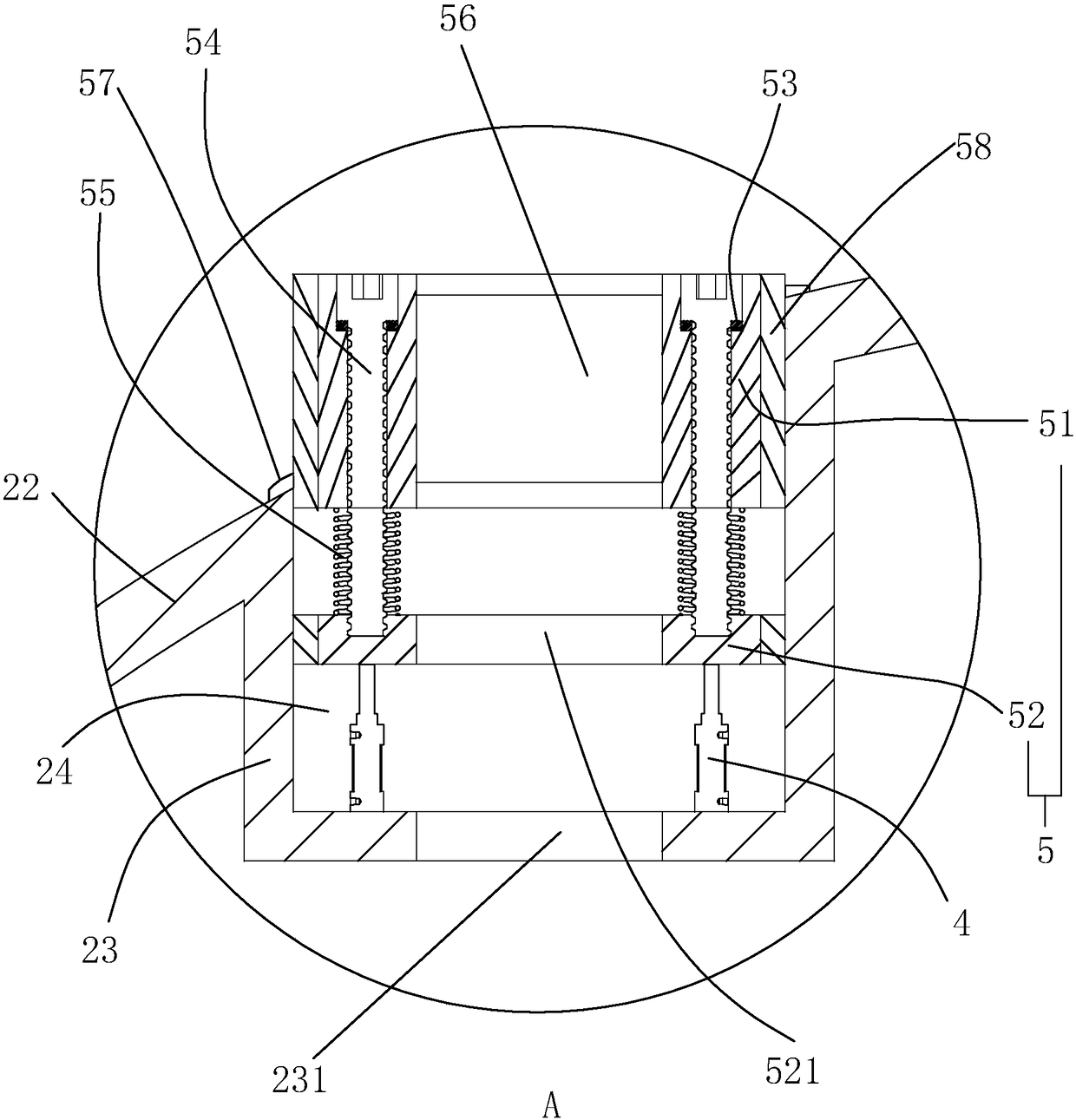

The invention provides a wet mixing granulator, and a solid preparation production line applying the wet mixing granulator. The wet mixing granulator comprises a material cylinder, a rotary shaft, a granulation cutter and a stirring paddle. The stirring paddle is fixed onto the rotary shaft; the rotary shaft is driven by a power device I to rotate; the granulation cutter is driven by a power device II to rotate; a first connecting rod is fixedly connected with the rotary shaft in a sleeved way; a first powder scraper blade pressing against an inner wall of the material cylinder is fixed to oneend of the first connecting rod; a second connecting rod capable of axially moving along the rotary shaft is arranged on the rotary shaft; a second powder scraper blade pressing against the inner wall of the material cylinder is fixed to one end of the second connecting rod; the first powder scraper blade is located on the upper end of the granulation cutter; the second powder scraper blade and the granulation cutter are located on the same height; the first powder scraper blade and the second powder scraper blade are arranged in a staggering way; a guide bar is arranged at one side, close tothe granulation cutter, of the interior of the material cylinder, and is located on the outer side of a cutting trace of the granulation cutter; the rotary shaft rotates to drive the first powder scraper blade and the second powder scraper blade to rotate circumferentially; when moving to one side of the granulation cutter, the second powder scraper blade presses against the outer side of the guide bar and moves in an extending direction of the guide bar.

Description

technical field [0001] The invention relates to pharmaceutical equipment, in particular to a wet mixing granulator and a solid preparation production line using the wet mixing granulator. Background technique [0002] The publication number is CN204746265U, which discloses a wet mixing granulator with an adjustable powder scraping device, which includes a pot body, a rotating shaft, a stirring paddle, a fixing device and a powder scraping device, and the paddle is installed on the rotating shaft at the bottom of the pot body; The fixing device is connected with the stirring paddle, and the powder scraping device is connected with the fixing device; the upper part of the rotating shaft is provided with an external thread, the lower part of the fixing device is hollow and the inner wall is provided with an internal thread matching the external thread of the rotating shaft; the powder scraping device consists of a powder scraping sheet, Composed of a transmission rod and a conn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J2/10

CPCB01J2/10

Inventor 沈贡民李卫平王晓露

Owner HANGZHOU GUOGUANG PHARMA

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com