Peanut gynophore removal sorting machine

A sorting machine and peanut technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of high labor intensity, easily damaged peanuts, not clean enough, etc., to achieve enhanced competitiveness, low cost, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

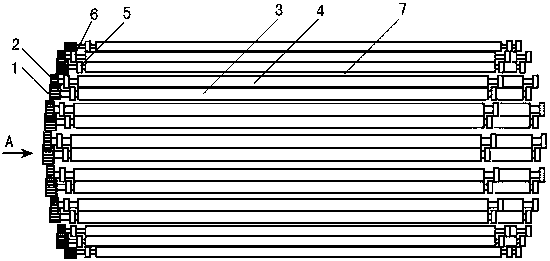

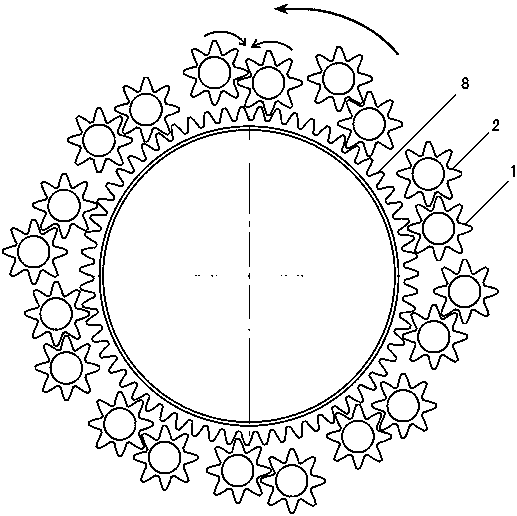

[0027] This embodiment is a barrel-shaped peanut sorting machine.

[0028] Such as figure 1 As shown in -3, the peanuts go to the selection machine, the driving roll 3 is fixed on the driving roll shaft (the driving roll 3 and the driving roll shaft are integrated), the driven roll 4 is fixed on the driven roll shaft (the driven roll 4 and the driven roller shaft as an integral structure); the front and rear ends of the driving roller shaft and the driven roller shaft are fixed on the front and rear roller frames through bearings (respectively, the driving roller bearing 5 and the driven roller bearing 6), and the roller frame is in the form of a ring status (see Image 6 , Figure 7 ); the driving roller shaft at the front end is provided with a driving gear 1, and the driven roller shaft at the front end is provided with a driven gear 2, and the driving gear 1 is meshed with the toothed disc 8 for transmission, and the toothed disc 8 is arranged side by side with the rolle...

Embodiment 2

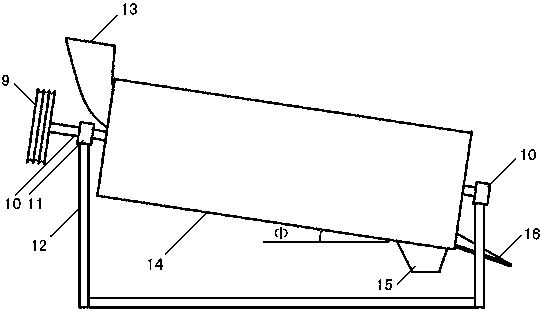

[0042] This embodiment is a plane-shaped peanut sorting machine.

[0043] Such as Figure 9 As shown, the selection machine for peanuts includes a frame 31, a power device, and a casing (not shown) fixed on the frame 31; several groups of driving rolls arranged horizontally and both ends of the driven rolls are directly arranged through bearings On the frame 31, several groups of driving rolls and driven rolls are placed with a high front and a low rear to form an inclined plane. The inclination angle of the inclined plane is 10°-30°, preferably 15°-25°. A supporting plate 29 is arranged below the driving roll and the driven roll; the roll gap between the driving roll and the driven roll is 0-0.8 mm, preferably 0-0.6 mm, and one group of driving rolls and the driven rolls are separated from another group of dry rolls. The group gap between the driving roll and the driven roll is 5-20 mm (considering the inclination angle of the inclined plane, the group gap should be increase...

Embodiment 3

[0049] This embodiment is another kind of planar peanut sorting machine.

[0050] Such as Figure 10As shown, the same as in Example 2, several sets of driving rolls and driven rolls are placed on a plane, and are placed with a high front and a low slope. The inclination angle of the slope is 10°-30°, preferably 15°-25°. There is a supporting plate under the driving roll and the driven roll; the roll gap between the driving roll and the driven roll is 0-0.8 mm, preferably 0-0.6 mm, and one group of driving rolls and driven rolls and another group of driving rolls The group gap 7 between the driven roll and the driven roll is 5-15 mm. The difference between this embodiment and embodiment 2 is that several sets of driving rolls and driven rolls in embodiment 2 are arranged horizontally, and several groups of driving rolls 1 and driven rolls 2 in embodiment 3 are arranged vertically, and the axes of the driving rolls and driven rolls are arranged vertically. The front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com