Temperature-dependent solid material thermal diffusion coefficient measuring device and method

A technology of thermal diffusivity and solid materials, which is applied in the field of thermal physical property testing of materials, can solve the problems of heavy measurement workload, etc., and achieve the effect of wide application range and low test environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

[0027] The invention provides a measuring device and method for the change of the thermal diffusivity of solid material with temperature.

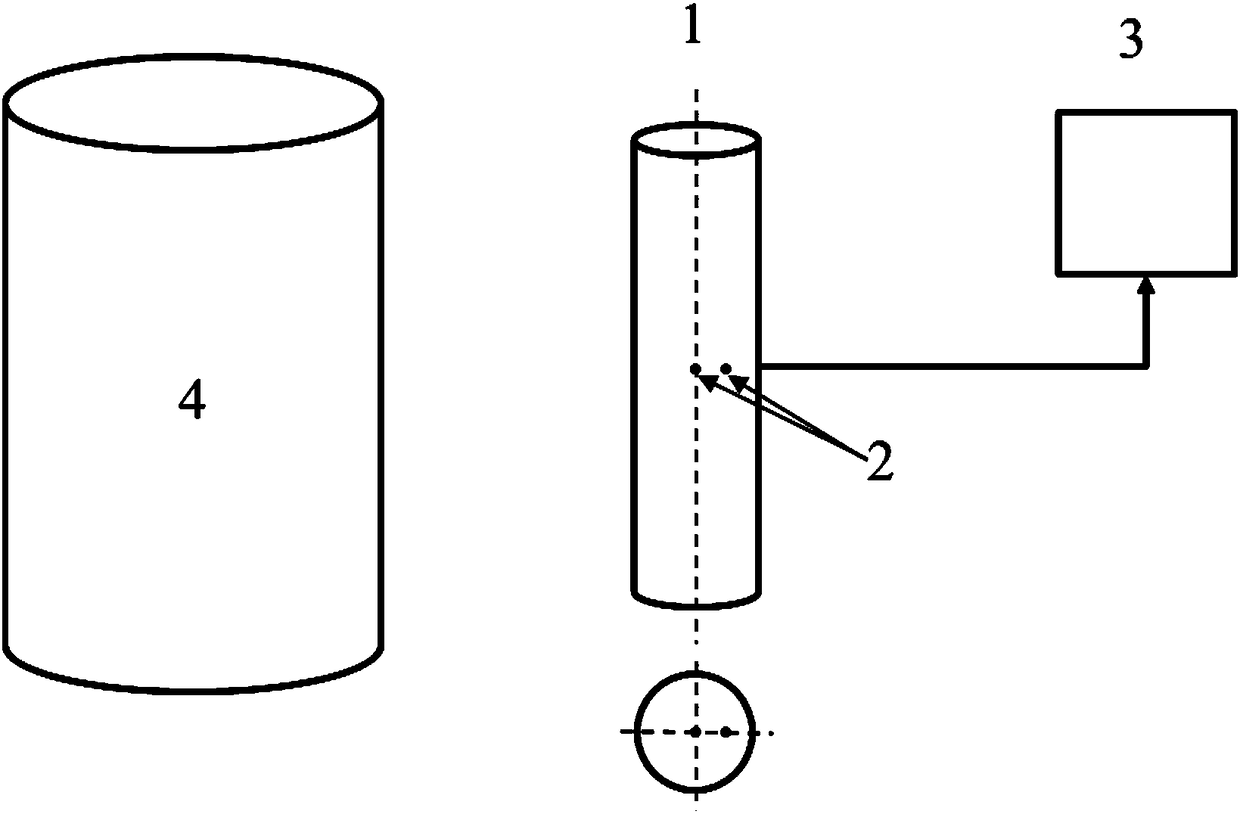

[0028] like figure 1 As shown, in this device, the armored micro temperature measuring thermocouple 2 is placed inside the cylindrical test material 1, the cylindrical test material 1 is placed in the constant temperature tube furnace 4, the cooling device is to cool the cylindrical test material 1, and the armored micro The temperature measuring thermocouple 2 is connected with the temperature recorder 3, and the temperature recorder 3 sends the data to the data analysis software. The length of the cylindrical test material 1 is more than 5 times the diameter.

[0029] There are two armored mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com