Micro drag chain

A towline and miniature technology, applied in the direction of towline, hanging chain, etc., can solve the problems of unreasonable structure, falling pipelines, inconvenient disassembly of the towline, etc., and achieves the effect of being suitable for maintenance, exquisite in structure and convenient in manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

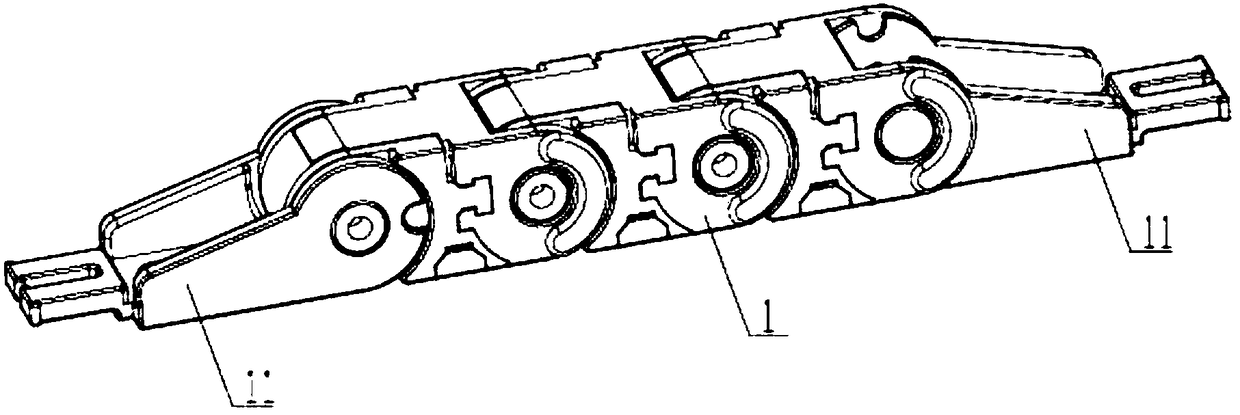

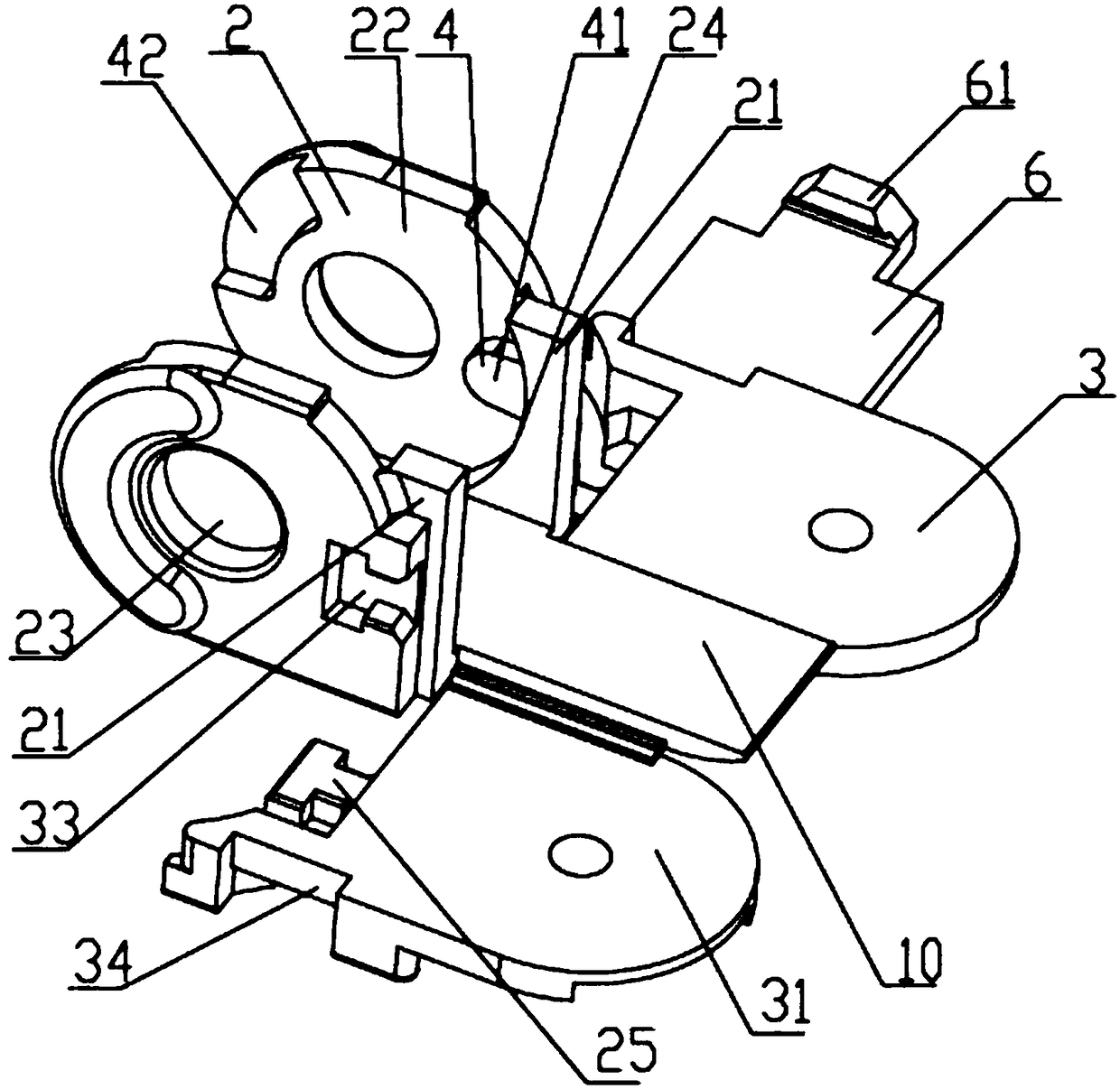

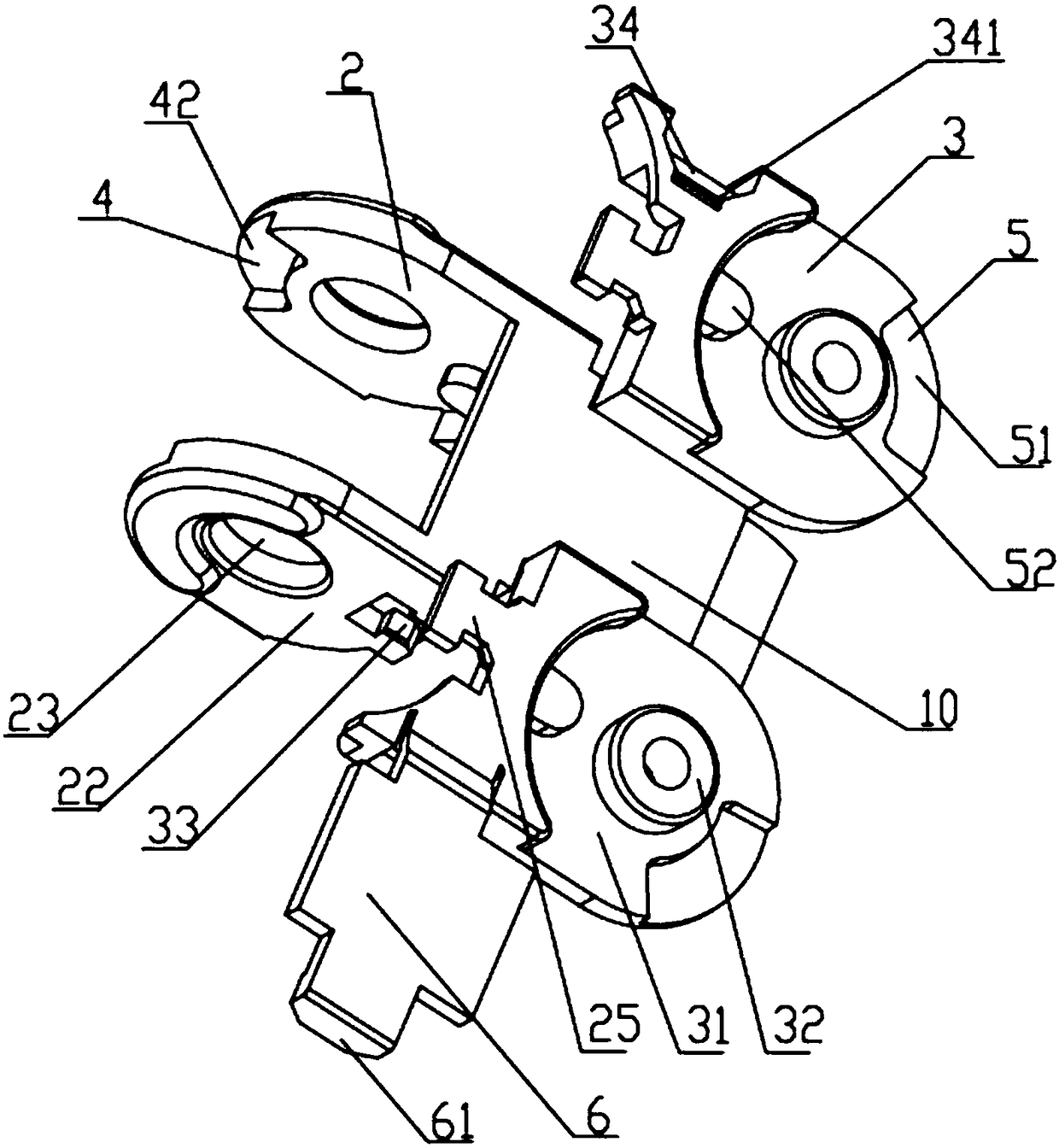

[0021] Such as Figure 1 to Figure 3 As shown, the present invention discloses a mini drag chain, which includes a group of base bodies 1 that are hinged and integrated with each other. And the connecting component 3, the fixing component 2 cooperates with the connecting component 3 on the front adjacent base 1 to form a storage space for accommodating pipelines.

[0022] Wherein, the fixing assembly 2 at least includes support plates 21 fixed on both sides of one end of the bottom plate 10 in a symmetrical structure, and a fixing plate 22 is fixed on the outside of each support plate 21, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com