Bearing Assembly Including Oil Quality Sensor

A technology of bearing components and sensors, which is applied in the direction of bearing assembly, bearing components, rotating bearings, etc., can solve the problem of expensive lubricants and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, identical or functionally equivalent elements are denoted by the same reference numerals.

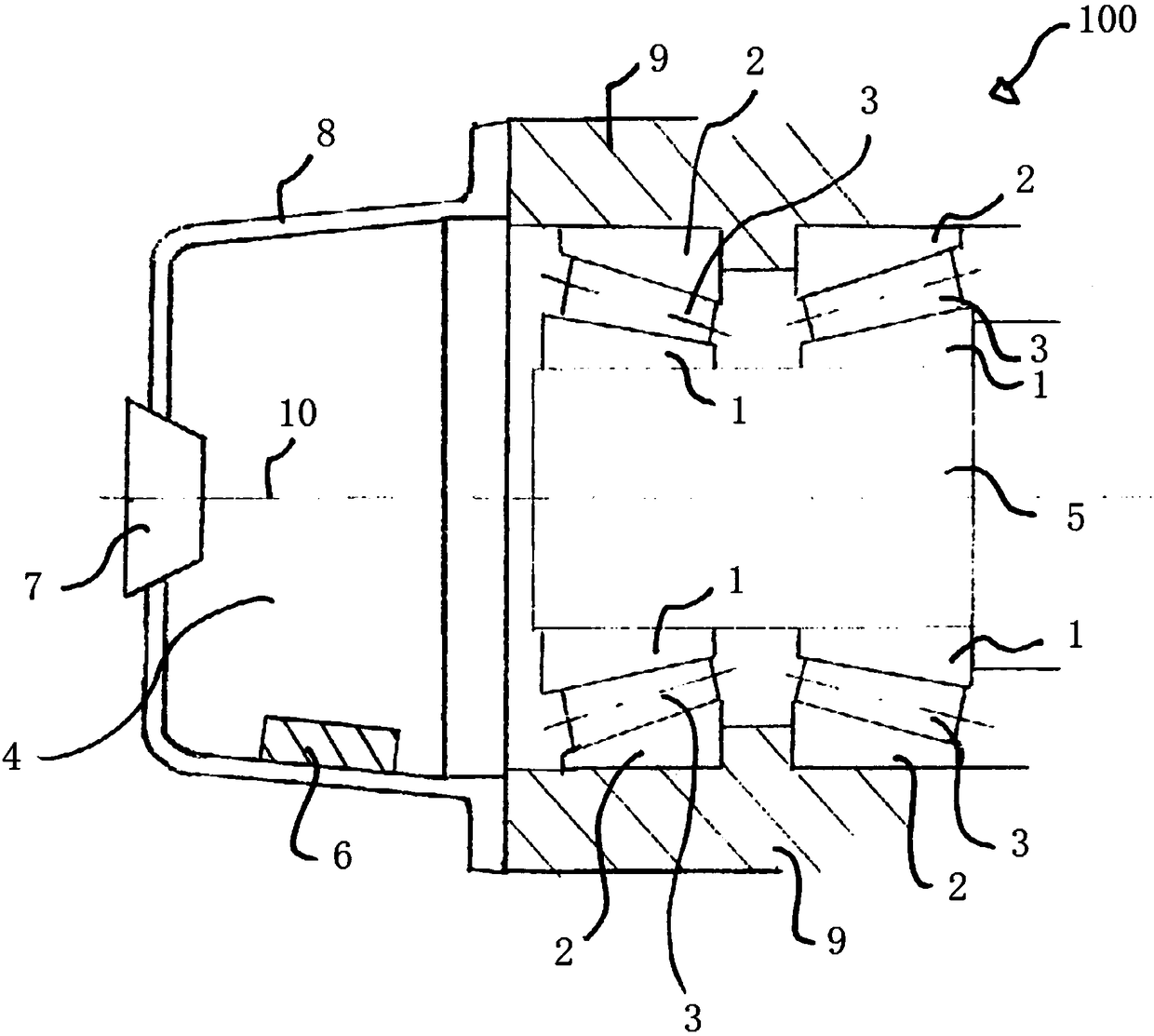

[0035] figure 1 A bearing assembly 100 is shown. Bearing assembly 100 may be a wheel bearing assembly for a motor vehicle. exist figure 1 In the exemplary embodiment shown, the bearing assembly comprises two bearings, each bearing comprising a first bearing ring 1 and a second bearing ring 2 arranged rotatably relative to each other. The (both) bearings are arranged on an axle 5 and each bearing comprises (located) a rolling body 3 between the first bearing ring 1 and the second bearing ring 2 . Lubricant 4 is provided in a sealed space that may be referred to as inside the bearing, including around the axle 5 and around the bearing (comprising the first bearing ring 1, the second bearing ring 2 and the rolling elements 3) ( around) area. Said lubricant is sealed with respect to the exterior by a housing 9 and a hub cover 8 which at least partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com