Positioning transferring device and technology for lighter automatic stacking machine

A technology for lighters and stackers, which is applied in packaging, transportation and packaging, and individual objects, and can solve problems such as failure to meet the yield rate, safety of explosive personnel, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

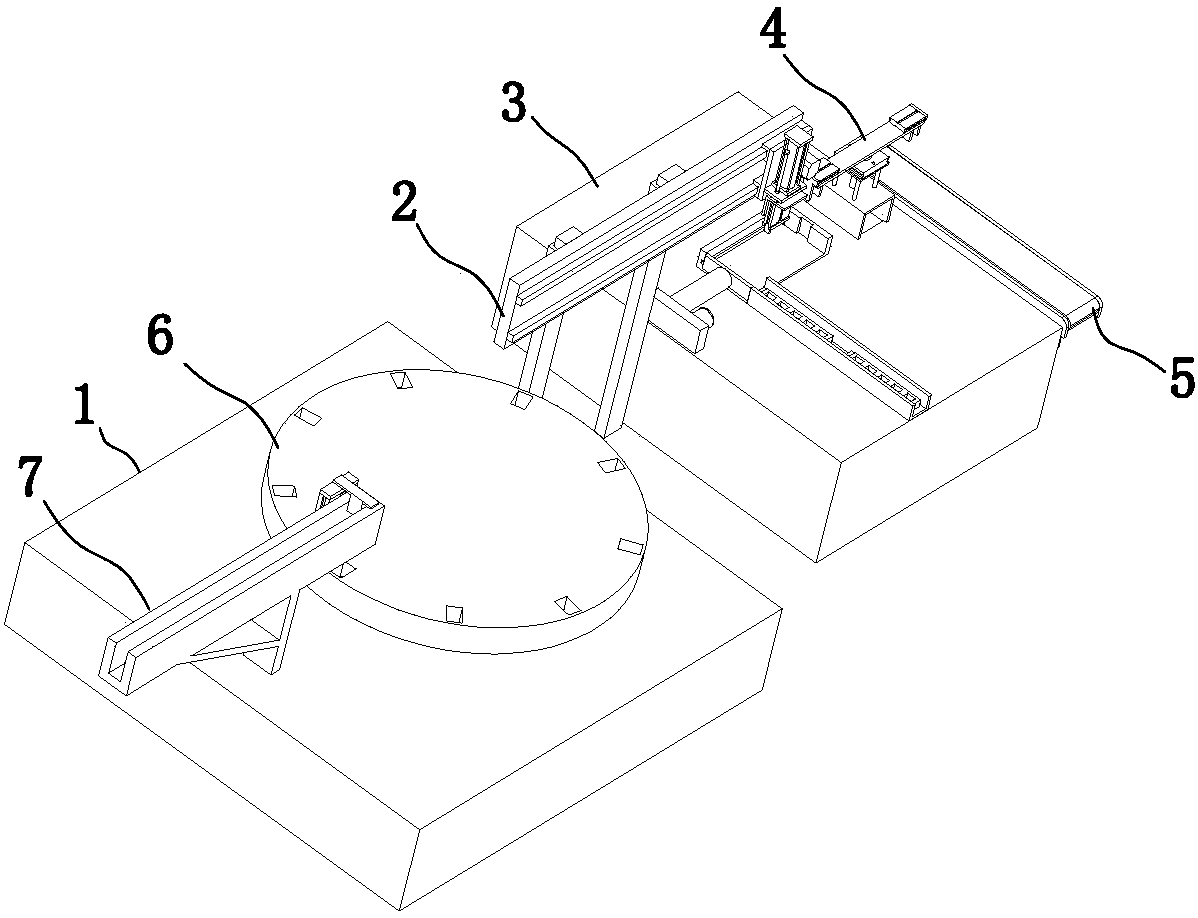

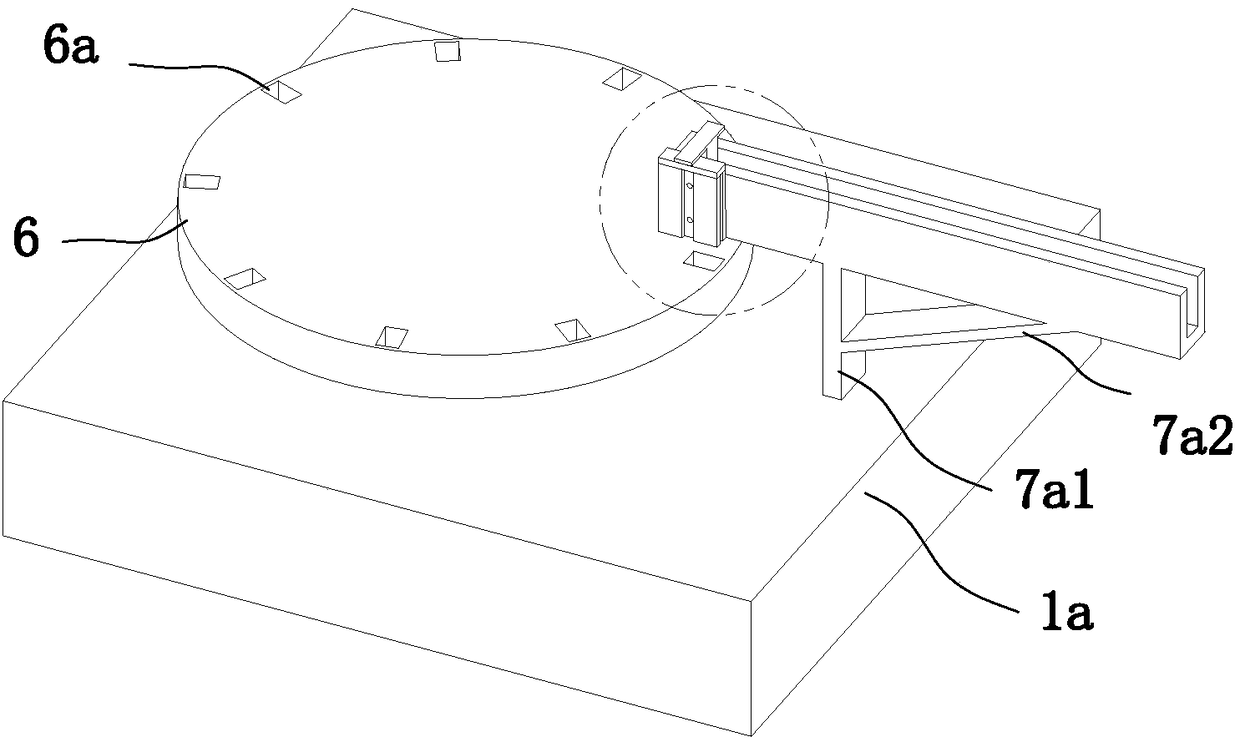

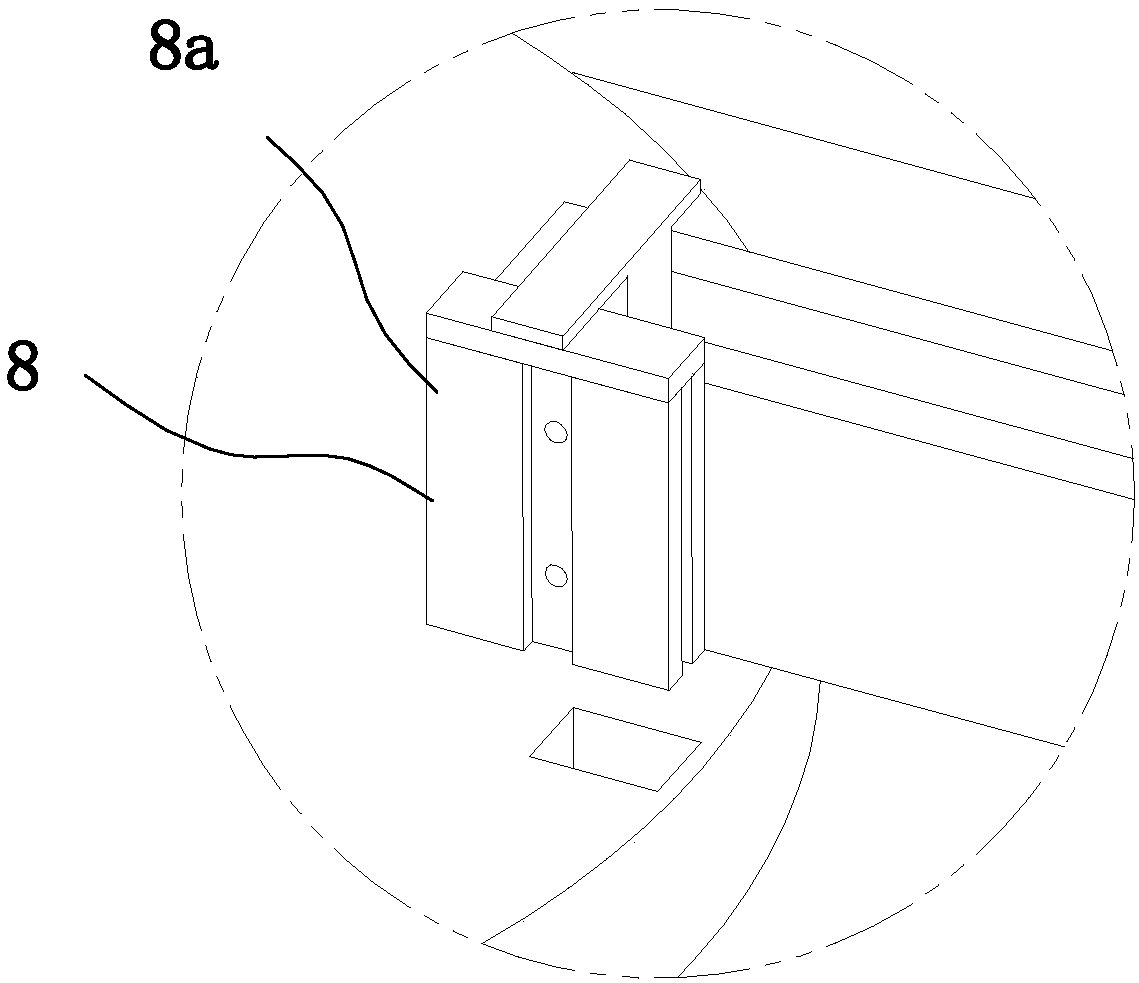

[0037] refer to Figure 1 to Figure 11 The shown lighter automatic stacking machine includes a feeding platform 1, a positioning shifting device 2, a supporting platform 3 and a feeding device 4, and the positioning shifting device 2 is located on the side of the feeding platform 1 and is adjacent to the top of the feeding platform 1. Cooperate, the supporting platform 3 is positioned at the side of the positioning shifting device 2 away from the feeding platform 1, and the unloading device 4 is positioned at the top of the supporting platform 3 and cooperates with the positioning shifting device 2, and the side of the supporting platform 3 is provided with The unloading conveyor belt 5, the unloading conveyor belt 5 cooperates with the unloading device 4 on the support platform 3, the top of the feeding platform 1 is provided with a turntable 6 that matches the positioning and shifting device 2 and directly above the turntable 6 The first conveyor belt 7 for transporting the ...

Embodiment 2

[0055] Please refer to the attached Figure 1-11 , the positioning and shifting process of the positioning and shifting device of the above-mentioned lighter automatic stacking machine includes the following steps:

[0056] S1. The positioning fixture 2e1 is conveyed by the second conveyor belt 2e3, and the positioning block 2e4 is located directly in front of the output end of the second conveyor belt 2e3;

[0057] S2. The translation assembly 2b slides to the specified position on the support assembly 2a, the lifting assembly 2c drives the air clamp 2d to move vertically downward to clamp the lighter on the turntable 6, the lifting assembly 2c drives the air clamp 2d to move vertically upwards and then translates the assembly 2b Move to just above the positioning jig 2e1;

[0058] S3. The lifting component 2c drives the air clamp 2d to move vertically downward, and the air clamp 2d inserts the lighter into the positioning fixture 2e1 of the positioning member 2e;

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com