Feeding device for granule pill filling machine

A technology for filling machines and pills, which is applied in packaging, solid materials, transportation and packaging, etc. It can solve problems such as the inability to ensure that the number of pills is always fixed, increase production costs, and the error rate of counting machines, so as to eliminate counting machine errors and reduce cost-wasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

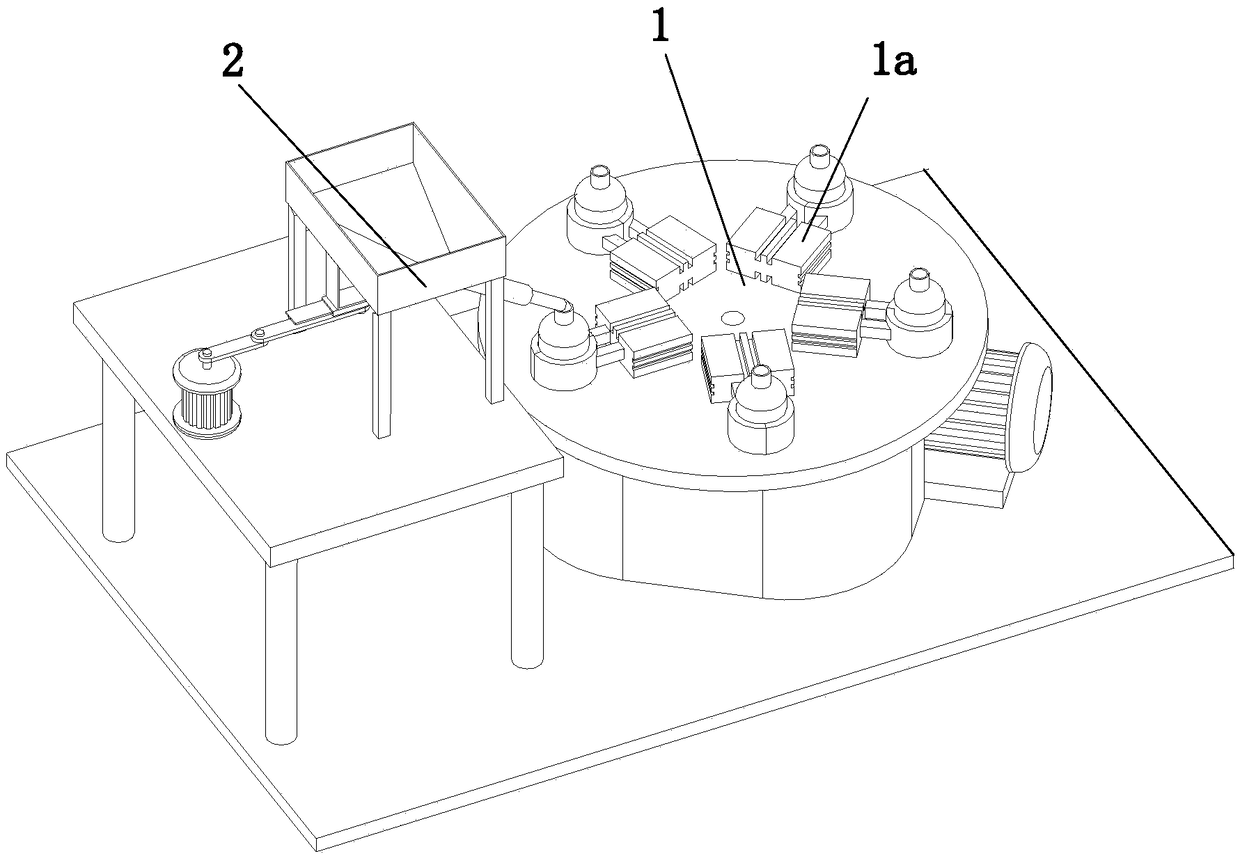

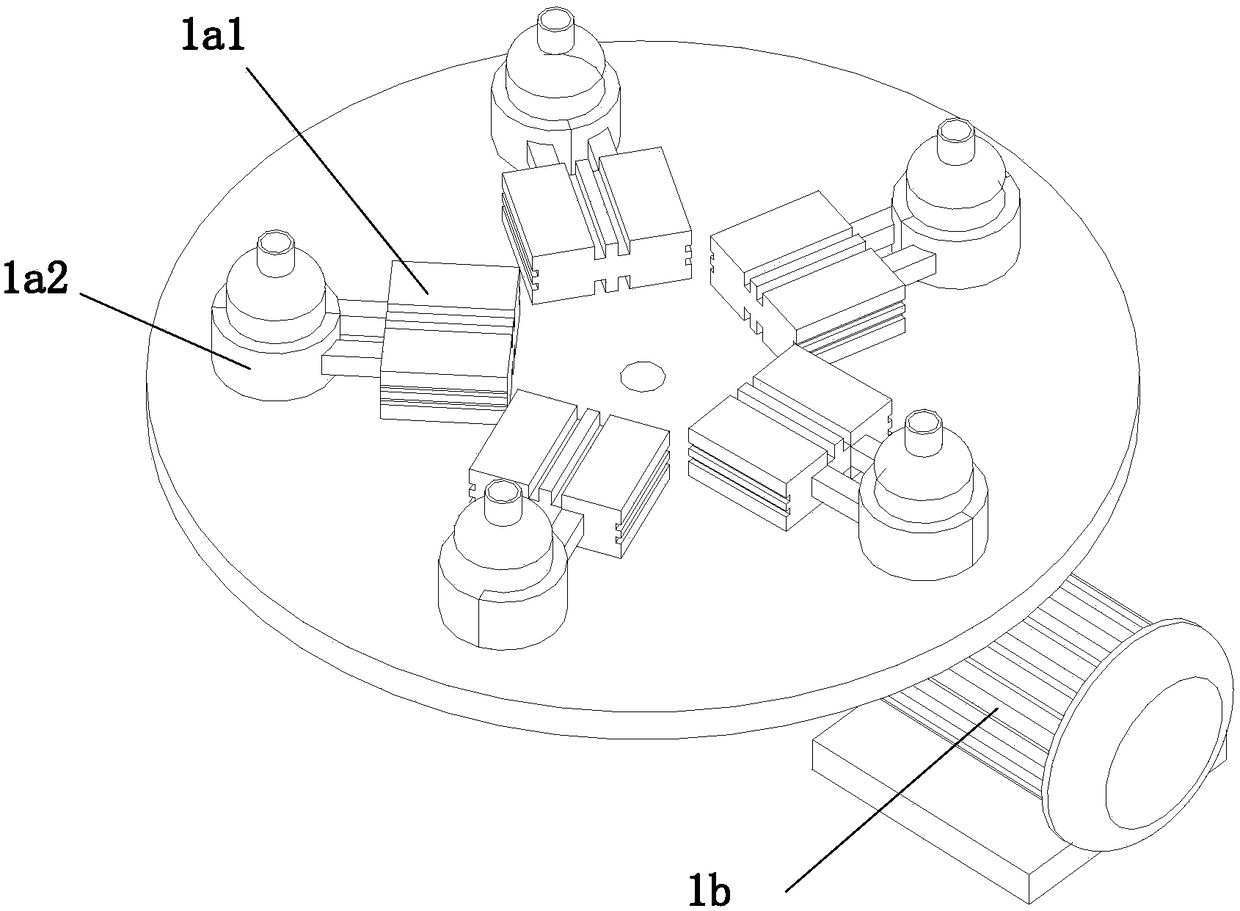

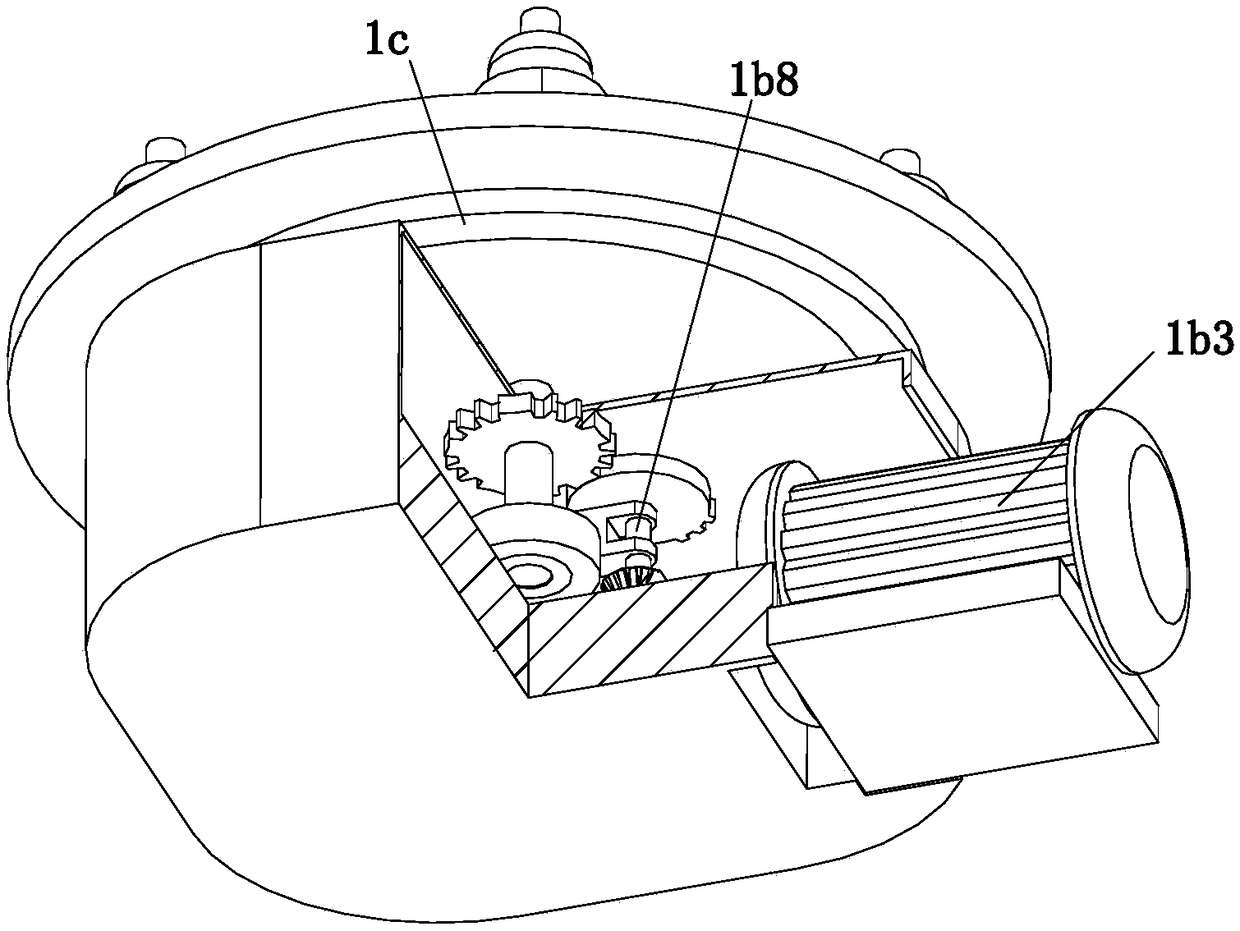

[0026] refer to Figure 1 to Figure 11 A granular pill filling machine shown includes a circular rotating platform 1 for carrying medicine bottles and a feeding device 2 for loading pills into the medicine bottles. The rotating platform 1 is provided with a The clamping assembly 1a of the medicine bottle, the bottom of the rotary platform 1 is provided with a first drive assembly 1b that drives the rotary platform 1 to rotate intermittently, the feeding device 2 includes a hopper 2a for loading pills, and is used to guide the pills from the hopper 2a enters the connecting pipe assembly 2b in the medicine bottle and the linkage assembly 2c used to control the on-off of the hopper 2a and the connecting pipe assembly 2b, the clamping assembly 1a holds several medicine bottles, and then the first driving assembly 1b drives the rotary platform 1 Intermittent rotation, so that all medicine bottles are filled with pills at the bottom of the connecting pipe assembly 2b in turn, and th...

specific Embodiment 2

[0038] refer to Figure 1 to Figure 11 A granular pill filling machine shown includes a circular rotating platform 1 for carrying medicine bottles and a feeding device 2 for loading pills into the medicine bottles. The rotating platform 1 is provided with a The clamping assembly 1a of the medicine bottle, the bottom of the rotary platform 1 is provided with a first drive assembly 1b that drives the rotary platform 1 to rotate intermittently, the feeding device 2 includes a hopper 2a for loading pills, and is used to guide the pills from the hopper 2a enters the connecting pipe assembly 2b in the medicine bottle and the linkage assembly 2c used to control the on-off of the hopper 2a and the connecting pipe assembly 2b, the clamping assembly 1a holds several medicine bottles, and then the first driving assembly 1b drives the rotary platform 1 Intermittent rotation, so that all medicine bottles are filled with pills at the bottom of the connecting pipe assembly 2b in turn, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com