Automatic grabbing-travelling device

An automatic, one-to-one technology, applied in the direction of motor vehicles, transportation and packaging, manipulators, etc., can solve the problem of single application range of automatic grabbing devices, and achieve the effects of improving operating efficiency, reducing floor space, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

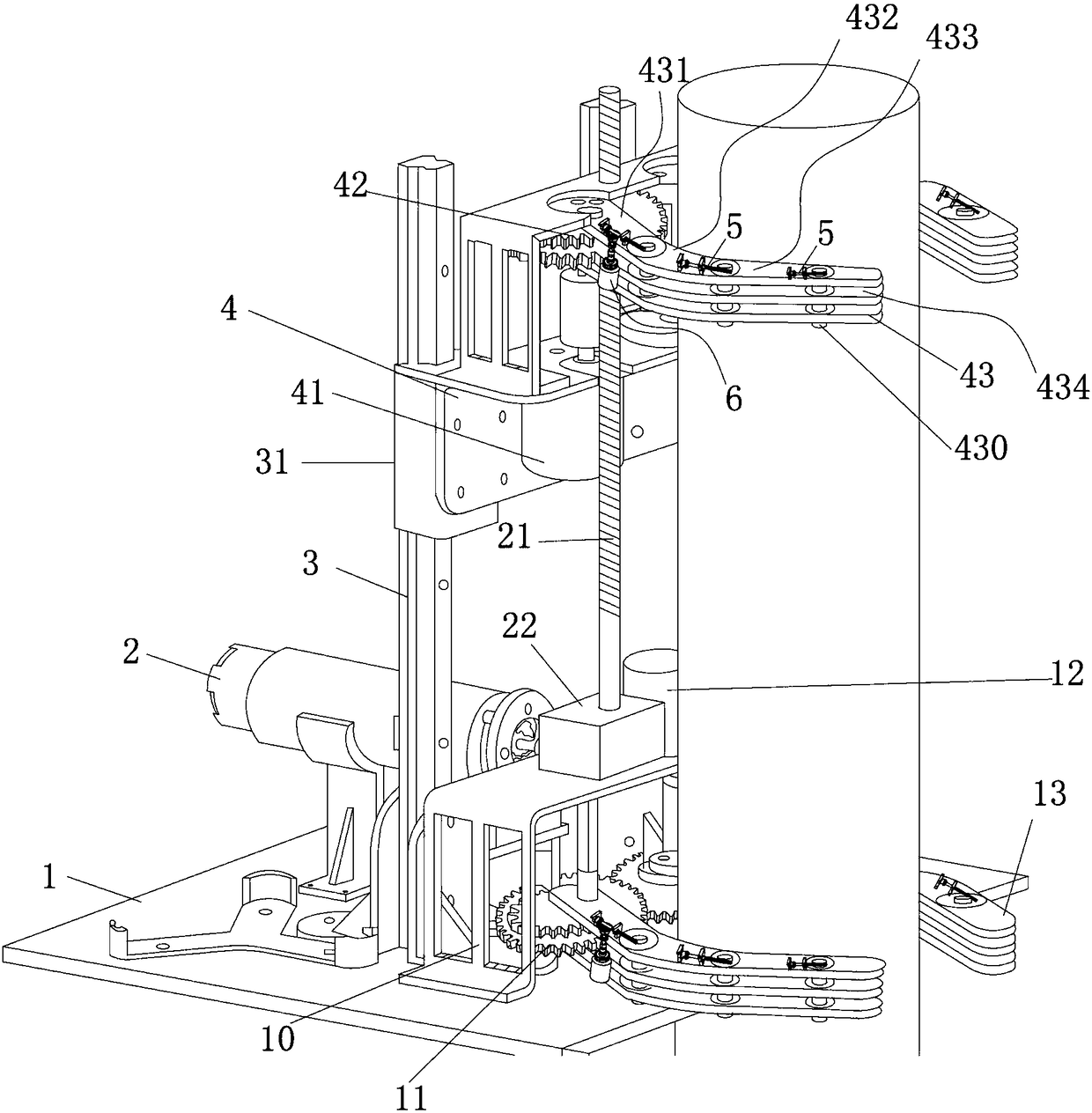

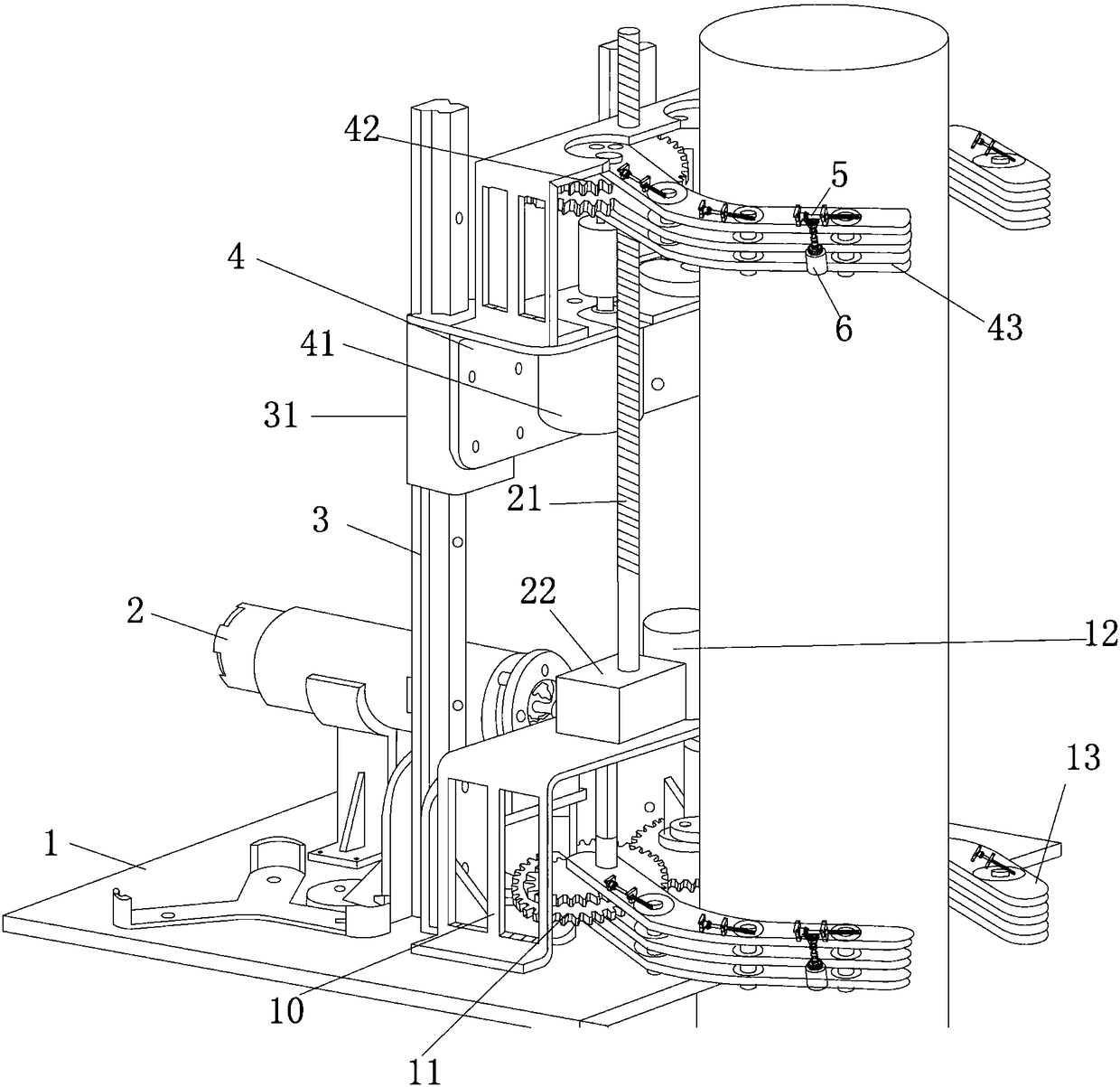

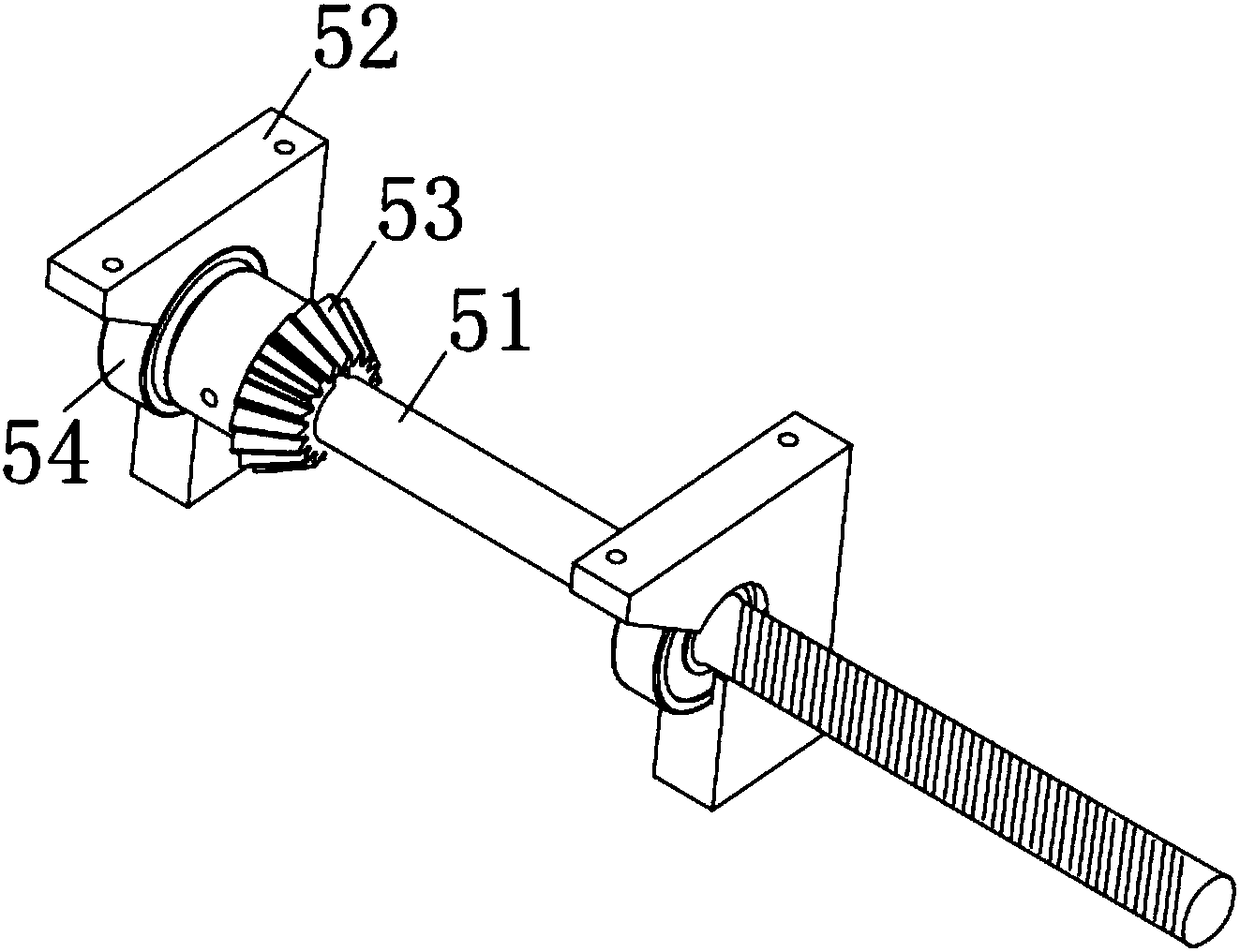

[0039] Such as Figure 1-5 As shown, the present invention provides an automatic grabbing device, including a display module, an infrared distance measuring module, a manipulator, a rotating and telescopic module, and a driving mechanism.

[0040] Specifically, the LCD display module is arranged on the top of the grabbing device to realize the real-time display of the status of the upper and lower manipulators and the current position of the grabbing device. The LCD display module is connected to the chip circuit of the grabbing device. Next to the LCD display module A number of buttons are installed, and the buttons are used to control the chip circuit, and finally the buttons control the start and stop of the movement of the gripping device, the gripping and releasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com