Sealing and locating clamp of blind cover of metal blade

A technology for positioning fixtures and blind covers, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

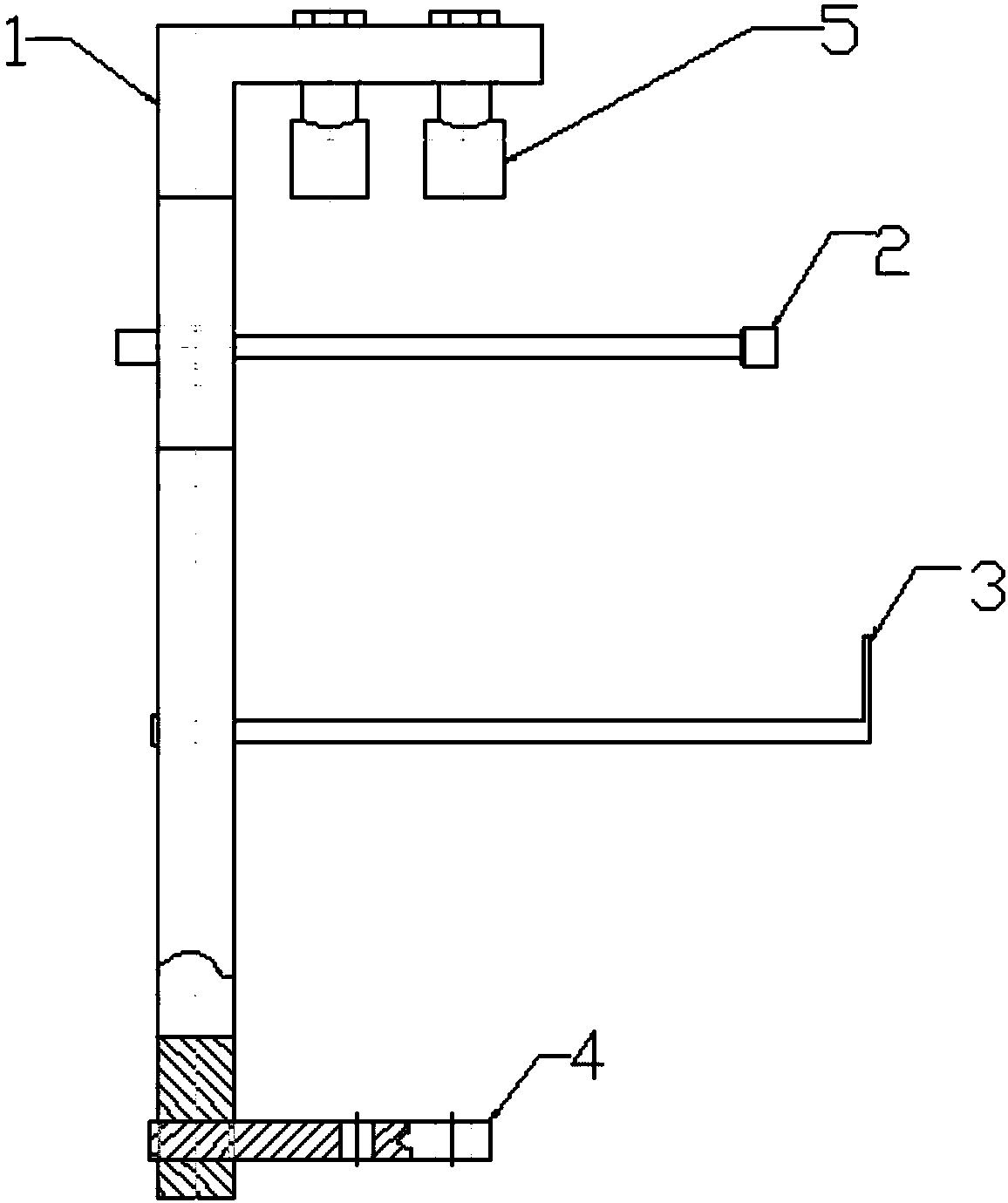

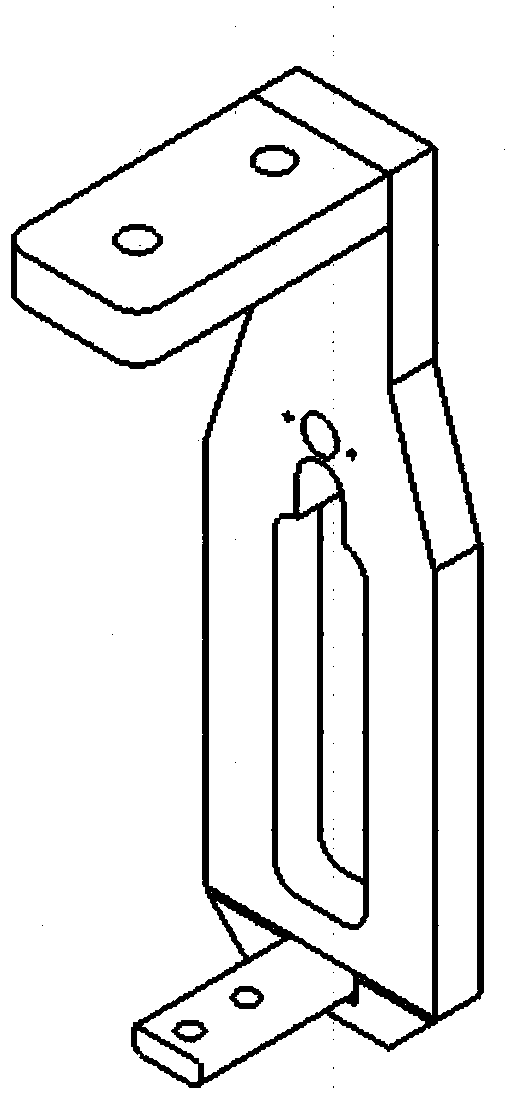

[0012] The present invention will be described in further detail below. refer to Figure 1-2 , in the sealing process of the blind cover, first put the blind cover into the inner cavity of the girder, install the positioning frame 1 on the tip of the girder, specifically, connect the tip of the girder and the fixing plate 4 through nuts, bolts, washers and washers The girders are connected, and then the girder leading edge adjusting device 5 is tightened to press the girder leading edge and keep close to it, then the pull rod 3 is screwed to the blind cap, and then the push rod 2 is used to push the blind cap to the set position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com